Tell me honestly, how do you store your woodworking tools, saws, drills, clamps, nuts, washers and a bunch of other little things you need in your garage or workshop? I think many will answer: in plastic buckets from under the paint or cardboard boxes. Moreover, “small things” are usually stored in the form of some kind of “assortment” and when you finally need some small key or nut, you need to spend a fair amount of time to find them. Sometimes it’s even easier to buy new parts than to find old ones. Are you familiar with this situation? If yes, then I suggest making a few simple and inexpensive devices for storing small items so that they are always in sight.

1. Storage of nails, self-tapping screws, screws and other small items

Plastic jars of mayonnaise, horseradish, etc. are useful for this. The lids from underneath are screwed to the horizontal surface of the shelf, and the jar with accessories is screwed to the lid. You can also screw the lid to a vertical surface and cut the jar in half.

2. Storage of nuts, washers, keys, scissors

You will need thick wire and perforated fiberboard sheet, which is attached to the wall of a workshop or garage. From wire we make hooks and loops with detachable ends, onto which we string nuts or washers. You can attach cardboard labels to such bundles indicating the sizes of the fittings. Scissors and keys can simply be hung on hooks.

3. Box for storing nails, screws and other small items

This mini bookcase can be made from plywood. And as shelves you can use cupcake stands or baking dishes.

4. Storage of drills, cutters and keys

You can attach a pad made of foamed polyethylene or polystyrene to the wall, in which we make small holes for drills, cutters, etc. Due to the elasticity of the material, they will be firmly fixed in the cells and easily removed.

5. Storage of circular saws and grinding wheels

For this purpose, we use plastic disposable plates, which we cut in half and fasten to the wall with self-tapping screws. Very simple, convenient and everything is at hand!

6. Magnetic boxes for small items

We use small plastic food containers. We glue a metal washer to the bottom of the container with super glue, and attach a strip with a magnetic strip to the wall. It is convenient to store all sorts of small items in such transparent containers.

7. Storing band saw blades

Using hooks and paper clips makes it easy to store band saw blades.

8. Storage of clamps

For clamps, a simple rectangular plywood box that is attached to the wall is very suitable. We place the handles of the clamps in the box.

Please rate this post:

A box for storing various small items and products is considered an indispensable attribute in a modern household. Thanks to this design, everything is in its place without creating clutter. For example, vegetables and fruits should be stored in a ventilated structure where fresh air can easily enter.

Monolithic products without any holes are suitable for tools. Designs with additional doors and a folding mechanism are suitable for various small items.

We offer original options DIY storage boxes. Here you will find out what materials and tools you will need to make these products.

What materials are used to build structures?

Most often, boxes are made of wood and other materials. For instruments, it is better to choose solid pine or maple. Alder or aspen is suitable for products. These tree species are distinguished by their durability and strength. They do not emit resinous secretions and do not dry out over time.

Plywood is suitable for making decorative items. You can place all sorts of little things here. To fix the parts, a special adhesive composition is used.

Master class on creating a box with your own hands

We offer step by step instructions how to make a box at home. To do this you will need the following tools and materials:

- tape measure;

- a simple pencil;

- board 25 mm thick;

- wooden edges 15 mm thick;

- thin plywood;

- metal corners;

- nails and screws;

- hacksaw;

- screwdriver;

- metal hinges for opening the lid structure;

- hammer.

First of all, you need to familiarize yourself with the diagrams and drawings of how to make a box. This will allow you to correctly compare the sizes finished product. You should not make too large structures, as they will take up a lot of free space.

When all the components are ready, you can proceed to making a storage system for vegetables and fruits. The process includes several stages:

On the surface of the boards we mark the size of the side parts of the product. Next we move on to the bottom of the box. We mark the size on the wooden edges. After this, using a hacksaw, we begin to cut out the blanks.

We fix the boards together using small nails. We attach the bottom parts using the same method.

The product cover consists of plywood sheet. It is installed on special hinges that allow you to control the closing process.

The photo of the DIY box shows the entire work process.

Tool storage box

This type of design is considered best idea DIY box. This product will allow you to keep all your working tools in one place. Here you can make additional sections for storing screws, nails and nuts.

To do this you need to prepare:

- thin board;

- thick plywood;

- hacksaw;

- electric jigsaw;

- hammer;

- screwdriver;

- tape measure;

- drawing of the finished product;

- metal corners.

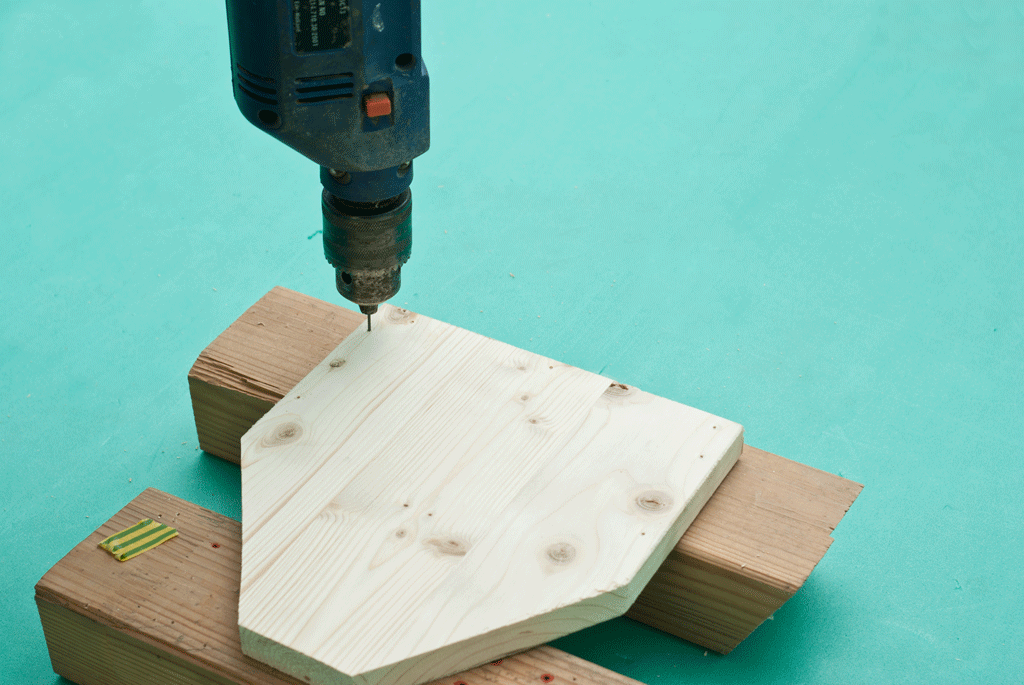

On sheets of thick plywood we make markings for the parts of the box. After this, we drill holes for fastening the metal hinges. Next, we connect the side parts to each other.

Let's start making the bottom for the storage system. To do this, we attach a thin board to the sides of the box. To prevent it from collapsing under the weight of tools, it must be strengthened with thin boards. To do this, several wooden elements are stuffed on the bottom surface.

On the side parts of the plywood we draw markings for the handles. They will be cut inside the main body of the product. Here you will need an electric jigsaw. The cutting base is installed at the beginning of the marking.

In the process of cutting out parts, you should not make sudden movements. They can cause cracks to appear on the surface of the product.

Now let's start installing the partitions. To do this from thin plywood cut out a small square. It is fixed with metal corners in the middle of the structure.

The diagram shows a detailed view of the tool box. The drawing shows the exact number of parts:

- side parts – 4 pcs.;

- bottom – 1 pc.;

- septal wall;

- handles – 2 pcs.

DIY photo of boxes

This article is about how to do wooden box for tools. If you have a lot of tools and want to keep them organized, the best thing you can do is create a simple toolbox out of wood. From our experience, we find them very useful as they are lightweight, durable and provide plenty of space for storing tools. Don't forget that you can adjust the size and design to suit your needs.

The main components of the tool box are made from 20mm boards as they have a beautiful appearance, and very durable. In addition, we recommend that you glue the joints and fasten everything with cuts. Try to screw in the screws as symmetrically as possible.

Once assembly is complete, you will need to sand the entire surface of the box. Make sure all edges are smooth. Otherwise, you may hurt your hands on the sharp edges. Also, be sure to check that all screw heads are level with wooden surface. Get rid of dust and shavings before painting.

What you need to make a wooden tool box

To make a wooden tool box, you will need the following:

Materials

Tools

- protective gloves, glasses;

- ruler, ;

- chalk, tape measure, level, carpenter's pencil;

- and drills.

Adviсe

- Pre-drill holes in wood components before installing screws.

- Make a handle from a cylindrical stick.

Time

- 1 hour

Box decoration

Making a simple wooden tool box is one of those projects that can be done in less than an hour. But it can make your life easier, especially if you work with tools a lot.

Smart Tip: Before joining the parts, add a little glue to the joints. Immediately remove excess adhesive with a dry cloth, otherwise it will be difficult to remove once it dries.

The first step of the project is marking. As you'll see in the next step of the project, we'll be using 1x8 boards to make a toolbox. Therefore, you should use a carpenter's pencil and a straight edge to mark the lines on the wooden boards.

In order to get precise cuts, we recommend using a jigsaw or a good circular saw. Make sure the saw has smooth teeth, otherwise it may tear off the edges.

Smart Tip: Also, make sure the blade will fit exactly along the cut line before sawing.

The picture shows all the components needed for the box. Circular machine can make the job easier since many cuts need to be made at an angle.

You should use this drawing when making components for the box. Make sure you double check all measurements, otherwise the components may not fit correctly.

After creation wooden parts, you need to drill holes around the edges. As you can see in the picture, you need planks on wooden block to prevent surface damage. Drill three holes in the bottom and two holes in the sides.

Smart Tip: If you are not experienced in woodworking, you should draw guidelines for pilot lines. Allow some space from the edges to prevent the wood from splitting.

If the edges of the bottom are not smooth, you should sand them thoroughly with 120- sandpaper before assembly.

Coat the bottom ends with wood glue to strengthen the connection. Remove excess glue with a dry cloth, otherwise you will waste time cleaning it.

Press the ingredients firmly and leave for half an hour. If you are using good glue, it will hold the joints together well.

However, still screw the screws into the drilled holes.

In order to receive robust construction, we recommend using self-tapping screws. Work carefully to prevent damage to wood components.

Smart Tip: Align all parts before twisting. As you can see in the picture, the edges should be smooth.

Once all the components are installed together, the toolbox should look similar to the one shown in the photo below.

Make a handle from a cylindrical wooden rod. The diameter of the handle is approximately 20 -25 mm.

Smart Tip: Use a ruler to cut the rod to the desired length.

Add a little wood glue to both ends of the rod before installing it in place. Then drill a hole and tighten the screw. Hold the handle while screwing, otherwise it may move out of place.

Smart Tip: Leave about 15mm from the top edge to the wooden handle.

Remember to smooth the edges of the wooden components with sandpaper.

Smart Tip: Clean the box of dust and shavings before painting.

Then completely sand the entire surface of the box with sandpaper.

Smart Tip: Apply several coats of paint, varnish or stain to improve the appearance of the wood and protect the materials from rotting.

If you want your drawer to have the same dimensions as in our article, we clarify that 1 inch equals 2.54 cm.

Any owner has a lot various instruments and fasteners. Sometimes all this is stored in a separate box, on or in, neatly folded or piled in a heap. Often, when starting or when it is necessary to tighten the nuts, you have to search for a long time for the right wrench, screwdriver or pliers. A multifunctional toolbox with compartments for wrenches, drills, fasteners, etc. You can buy it in a store or make it yourself. In today's review by the editors of the site, we will look at the types of boxes for, what you can make from and how to assemble them with your own hands.

Tool boxes differ in the material used and the type of items stored. According to the material used they can be:

- wooden. Wood is an affordable and easy to process material. To make the box, use either durable multilayer plywood 10, 16 or 18 mm thick. The complexity of the design depends on the wishes and skills of the master;

- metal. Steel or iron structures Quite heavy, but strong and durable. Lighter boxes are made of aluminum;

- plastic. These boxes are lightweight, durable, convenient and have a modern design.

The boxes also differ in the type of tool stored in them and are:

- Unprofessional. They are a design with several compartments. They use bags or cases of different sizes.

- Power tool. Special boxes used for storing drills, etc. As a rule, such boxes are equipped with a large compartment for certain equipment and several small ones for additional equipment.

- Professional. Most craftsmen prefer this particular type of tool box, since they have separate seats, for a certain type of equipment.

- Universal. Boxes of this type have a large number of compartments and are used to store a wide variety of. There are tool boxes with removable partitions, which allows you to rebuild inner space at our own discretion.

Design of tool boxes

Tool boxes are also divided by design. And here it is not the shape of the box that is meant, but the opening option and the presence of auxiliary compartments. The following designs are distinguished:

- case. It is a rectangular box with a handle. They usually have several compartments and removable partitions, allowing you to plan the interior space as you wish. Such designs are small in size and weight;

- container. A fairly spacious box with partitions and separate containers that fold like a nesting doll. Sections can be folded up and to the sides, and the box itself is often equipped with wheels for easy transportation;

- multibox. This is a vertically positioned design in which the drawers and hardware are pulled out like in a traditional linen chest of drawers.

Requirements for tool boxes

When choosing a tool box in a store or deciding to make it yourself, you need to take into account some of the requirements for its design:

- The bottom of the box or container must be sufficiently thick and durable, since this is where the bulk of the contents fall.

- When the box is fully loaded and lifted, its walls should not be deformed.

- It is recommended to choose a structure made of fire-resistant material.

- There should be no gaps in the box so that dust and dirt do not get inside and contaminate what is stored in it.

For your information! If you decide to purchase a tool box in a store, then give preference to multifunctional models with separate compartments and a closed insert organizer for small parts and fasteners.

Related article:

: what you should definitely have on hand. Read our publication for the main differences between similar tools, advice and recommendations from experts.

How to Make a Simple Open Tool Box

Inexpensive wood is most often used to make a tool box, especially if this is your first experience. We suggest making the simplest box without a lid. Its advantage is that it can fit and carry almost any size.

To make the simplest tool box You will need a board, wood glue, screws, or a drill and a hacksaw. The simplest box consists of:

- long walls (front and back) – 2 pcs.;

- narrow and high sidewalls (the height of the front and back wall should be larger, since a handle will be attached to them) - 2 pcs.;

- bottom (from a thick board) – 1 pc.;

- handles (square or round block, galvanized, chrome or aluminum tube) – 1 pc.

Assemble all the parts into a single structure using wood glue and. Please pay attention Special attention handle attachment. This box can be supplemented internal partitions(removable or stationary), and also make a cover. Dimensions can be very different: it all depends on your needs and desires. Photos of the assembly are shown below.

Tool box made of plywood

First of all, you need to make a drawing and calculations and transfer them to plywood. Carefully mark, cut out parts along the intended contours and make grooves, thanks to which the structure will be more durable. All cuts must be sanded with sandpaper.

Next, the box is assembled. Glue is used to connect the parts. First, the frame is glued together (to make the work easier, you can use clamps or rubber rings). The handle is made from MDF and carefully processed or used from an old case or suitcase. To keep everything in its place in the box, you can make small compartments. One part of the box is reserved for a compartment for storing screwdrivers.

Related article:

: the best home gadgets that any self-respecting home owner should have at hand are in our publication.

Wooden organizer with lid

This design is excellent for storing equipment, and is also durable, reliable and solid in appearance. To make it you will need:

- board;

- wood glue;

- metal corner pads – 8 pcs.;

- pen;

- self-tapping screws;

- furniture hinges – 2 pcs. or piano loop;

- latches-locks – 2 pcs.;

- drill;

- clamps;

- sandpaper.

Mark the parts on the boards according to the dimensions given below.

Detailing

| Name | Drawing number and quantity |

| Main drawer | |

| Front Panel | No. 1 – 1 pc. |

| Back panel | No. 2 – 1 pc. |

| Bottom | No. 3 – 1 pc. |

| Support rail | No. 5 – 2 pcs. |

| Side | No. 6 – 2 pcs. |

| Lid | |

| Top | No. 4 – 1 pc. |

| Front and back wall | No. 7 – 2 pcs. |

| Side | No. 8 – 2 pcs. |

| Removable tray | |

| Pen | No. 9 – 1 pc. |

| Bottom | No. 10 – 1 pc. |

| Long sides | No. 11 – 2 pcs. |

| Short sides | No. 12 – 2 pcs. |

| Partition | No. 13 – 2 pcs. |

Assembling the tool box

First of all, we assemble the box body and lid. To make it easier, use clamps and corner ties. The parts are connected using a special glue for carpentry. After the glue has dried, we drill holes, countersink them and carry out additional fixation with self-tapping screws.

Next, we assemble the removable tray in the same way, install partitions and additionally secure everything with self-tapping screws. Inside the body of the box, we install two strips on the short walls, spaced 300 mm from the top edge.

Once again we treat the tool box with fine abrasive paper to remove the slightest burrs. Cover the structure protective composition and let dry. If, after such treatment, raised wood fibers are found, then it is necessary to sand the box again and repeat the finishing.

To complete the assembly, you need to connect the cover to the body using hinges and self-tapping screws. Install the handle and latches-locks, as well as protective metal covers on all corners of the drawer. The box is ready and now you can fill it out necessary equipment, and fasteners.

A few words in conclusion

A tool box is a must-have item for any craftsman. You can buy it at any hardware store or make it yourself according to your needs. We hope that the above examples of making tool boxes will be useful to you. if you have own ideas, then share them in the comment form.

Household tools have an amazing ability to get lost at the most inopportune moment. If hammers and screwdrivers are used periodically, they are stored anywhere: mezzanines, cabinet shelves, balconies.

Therefore, when the wife asks to hang a shelf, remembering exactly where the drill and screws are located will be problematic. It is much more practical and efficient to store tools in a special box, which can be purchased ready-made or made with your own hands.

What to choose

Let us immediately note that the tool box can be different, and the shape and dimensions directly depend on what is supposed to be stored inside the case.

For hand tools. Usually this is a rectangular design with a handle, where the internal space is divided into one large compartment and 2-3 smaller compartments. It is convenient to store hammers, screwdrivers, and fasteners here.

For power tools. Such cases are usually produced by the manufacturer of the instrument itself. Standard option: portable box, where one cell is reserved for a power tool and exactly repeats its shape, the rest are intended for equipment: drills, batteries, etc.

Organizers. These are modular designs consisting of several drawers various forms and sizes. These options are suitable for professionals and home craftsmen; they are easy to store and transport, and help you quickly find any small item.

When the problem of storing a tool arises, the first thing that comes to mind is to purchase a ready-made tool box in a store. However, this is not the most the best option. The fact is that factory designs are aimed at the average buyer, so they may not be suitable for a specific model of an angle grinder or drill. In addition, the number of tools usually increases and the internal space becomes small.

To avoid these problems, you can make your own tool box with a little effort and creativity.

From boards

If there are few tools, they are used periodically and only for home use, there is no point in manufacturing a complex structure. It is enough to make an ordinary wooden box from boards so that screwdrivers, hammers and screws are simply in one place and not lying around the entire apartment.

Considering that we are talking about an elementary product, you can do without a preliminary drawing. The main thing is to decide on the size of the sides. For the material of manufacture it is better to choose edged board coniferous species: this is the most affordable option, which is easy to process.

The homemade box consists of 5 parts:

- 2 side walls;

- 2 end walls;

The elements are cut out in accordance with the planned dimensions, treated with sandpaper and fastened together with self-tapping screws. For greater reliability, the side parts can be fixed with metal corners.

This homemade wooden box is inconvenient to carry, but it will help you store your tools in one place and not have to look for them throughout the apartment. It can be placed in the trunk of a car, on a pantry shelf or in the garage. Sizes vary depending on what exactly is supposed to be stored inside.

From plywood

DIY plywood tool boxes are eye-catching interesting design. They are easy to use and emphasize the professionalism and qualifications of the home craftsman.

Comfortable plywood box with a handle will consist of the following elements:

- bottom – dimensions 450*200 mm, a shallow groove is cut in the middle for a transverse partition;

- walls - cut out in the amount of 4 pieces. A groove is also cut in the middle of the end elements;

- cross post - recommended height 400 mm, length adjusted to the width of the bottom, taking into account the sidewalls. The upper corners of the rack are cut down to create a trapezoidal shape.

The assembly is carried out according to this scheme. To begin with, the body elements are glued together, pressing tightly against each other. While the glue dries, a hole is cut out in the transverse post, which will serve as a handle; wooden dies can be glued to the upper part for ease of grip. Next, the stand is installed in pre-prepared grooves and fixed with glue.

After completing the work, you get a plywood tool box, convenient for carrying. However, you can make the design more functional. To do this, to transverse septum wooden dies are glued in advance drilled holes, where you can place screwdrivers, pliers, side cutters and other tools necessary for doing homework.

To prevent the box from drying out, it is coated with several layers of varnish. For greater reliability, if desired, the bottom is secured to the walls with corners.

Transformation into a stool

From plywood and wooden blocks you can make a portable box for storing tools, which, when turned upside down, will turn into a simple stool or stand for performing work at heights. This is being manufactured universal design according to this scheme.

The bars are cut according to the specified size. They will serve as legs and be located at an angle. To make the stool stable, the upper and lower ends are cut at an angle of 15 degrees.

Sheets of plywood are nailed to the legs, which will become end walls. The recommended width is 360 mm, the height is selected in such a way as to completely hide the legs without protruding beyond their limits.

The side walls are cut out of plywood and occupy approximately half the width of the block. The edges of the rectangle are cut at an angle to exactly match the angle of the legs.

The cover is made rectangular and attached to the ends of the racks with self-tapping screws.

After the work is done, turn the resulting stool upside down, turning it into a deep box for storing tools. To make the structure convenient to carry, a wooden block is cut out, the length of which will correspond to the distance between the walls. Round off sharp corners, screw the block with self-tapping screws and get a comfortable handle, which additionally serves as a stiffener.

Organizer box

It's more complex design, but it is ideal for storing large tools and additional small items: fasteners, corners, nails and much more. At first glance, such boxes seem to be a complex mechanism, but in fact they can be made independently by spending a little free time.

The manufacturing process is conventionally divided into 3 stages:

- We assemble the body. This is a deep plywood box with an open top, which is intended for storing large tools, such as an angle grinder, a screwdriver or an electric drill. However, you can do the opposite: delimit the internal space into several sections with wooden blocks and store bolts, nuts and screws here;

- additional boxes. There will be 4 of them, and they are installed on top of the main box, which must be taken into account when determining the dimensions. Additional drawers should not extend beyond the boundaries of the base. To give the structure a complete look, the upper boxes are equipped with lids;

- individual elements are combined into a single whole. To do this, the organizer is assembled into a finished form, markings are made on the walls for installing metal plates: 3 pieces for a group of drawers on each side. Then, in accordance with the applied markings, holes are drilled where the bushings are installed.

To make the organizer easy to carry, the top drawers can be additionally equipped with handles.

Note that here are the most simple options. With a little effort you can turn regular box for tools into a work of art that will become a real decoration of the garage, country house and a city apartment.