Simple and traditionally used in all culinary cultures of the world, cold smoking technology is designed to obtain appetizing snacks from fish and various types of meat.

A private smokehouse in the house or in the country will diversify the process of preparing delicacies, especially when it comes to avid fishermen and hunters.

This simple and stove-like device can be assembled from available tools in various situations.

Do-it-yourself collapsible smokehouse

You can build a temporary smokehouse right on the fishing spot, or make a stationary structure in the courtyard of the house, which will give room for culinary imagination and allow you to enjoy the unique smoked taste without harming your health.

The main principle of smoking is long-term fumigation with smoke at a certain temperature of pre-salted products.

Therefore, before starting to study various recipes for smoked fish or sausage, you need to get a smokehouse - a chamber in which smoke will be generated in the right mode and with the desired properties.

The main working device of the smokehouse is a smoke generator, which can be made from improvised means.

A food chamber can be built, giving a second life to a damaged refrigerator, gas stove, metal barrels and cylinders.

A portable and collapsible home-made smokehouse is the most convenient to use. It can be disassembled and stored, as well as taken out for picnics, hunting and fishing.

The prefabricated design allows for improvements, parts and containers to be replaced. To make such a smoking machine, you will need an old gas cylinder, two metal barrels, steel plates and rods, 5 half-meter pipe sections with a diameter of 10 cm, from tools - a grinder, a drill and a welding machine.

The gas cylinder becomes a firebox, smoking chambers are cut out of metal barrels, in which metal nets and rods for products are installed.

A chimney is mounted from the pipes, into which a home-made smoke generator is inserted - a device for producing and supplying smoke to chambers with products. In this case, the smoke temperature is regulated by the length of the removable pipe.

The principle of operation and assembly of the smoke generator

Before making a smoke generator with your own hands, you need to imagine the principle of the smokehouse: in the firebox, due to constant heating, the combustible material smolders, the smoke passing through the pipe is cooled to the desired temperature - from 20 to 40 degrees Celsius, depending on the processed product.

Here, the purification of harmful impurities and condensate settling takes place, after which the smoke enters the smoking chamber to fulfill its purpose.

The body of a smoke generator for smoking can be any metal utensil, for example, a can or a deep saucepan, in the lid of which you need to drill a hole for a fitting - a part connected to the chimney.

Sawdust intended for burning is placed on the bottom of the container, on the side, at a height of about 3 cm from the bottom, an ignition hole must be provided.

Then a connection for the aquarium compressor is made in the housing, and opposite the firebox there is a hole for the chimney, which is connected to the chamber with food.

The photo shows how a homemade smokehouse with a smoke generator might look like.

Note!

Variety of smoke generator designs

The appearance and functionality of a homemade smoke generator depends on the situation. Temporary structures can be built in 5 minutes, but with a more serious approach, you can get factory quality and aesthetics.

The smoke generator compressor can be installed both from the bottom and to the top of the casing. Instead of an aquarium processor, you can use any other electric pump, with a capacity of 4-5 watts.

The main purpose of the compressor is to supply oxygen for combustion, so craftsmen can adapt coolers and fans from various devices for this purpose.

There are many options for the selection of the body, it can be made of a heat-resistant pipe, you can use various options for outlet pipes, supplement the design with a container for collecting condensate, an ordinary water tee is used as an ejector.

You can improve the ignition point by attaching a metal spiral to the bottom of the case.

Note!

Do-it-yourself photo of a smoke generator

Note!

Smoke fish, meat or game is not just about increasing the shelf life of meat products. This is a unique opportunity to change their taste in a positive way. And although modern technology offers many options for changing taste, smoking is still a popular operation. Of course, manufacturers today offer different designs of smoking installations. But making a smokehouse and installing a smoke generator in it with your own hands is not only cheap, it is quite simple.

The most important thing is that there are no complicated devices here. Any installation can be made from scrap materials, often used materials, and often those that are supposed to be thrown into the trash. After all, the smoking technology is very simple. It is based on the fact that the smoke from burning wood enters the chamber where meat products are hung. Being impregnated with smoke, they are canned and get the same extraordinary taste and smell. Of course, the wood species used in the smoking process will play an important role. Experts recommend choosing chocks from fruit trees for this.

Smokehouse design

The scheme is simple. This device consists of two parts:

- Firewood is burned in one. In this case, they, in principle, should not burn. The main process is smoldering. That is why it is so important that there is little oxygen (fresh air) entering this chamber.

- In the second chamber of the smokehouse, carcasses (fish, poultry, pieces of meat) are hung.

Both chambers are connected by a pipeline through which the smoke from the smoldering wood will move. At the same time, the more smoke comes into the second chamber, the more intense the smoking process will take place. In the same chamber, a small hole must be made to remove excess smoke. The same hole will serve as a chimney to create a rarefied atmosphere inside.

There is, however, one negative point in this smoking installation. In order for the pledged products to be smoked inside for several hours, it is necessary to keep the firewood smoldering all the time, throwing additional lumps into them. Therefore, you have to be near the smokehouse all the time. You can get rid of this if you make a smoke generator for cold smoking with your own hands.

What is a smokehouse smoke generator

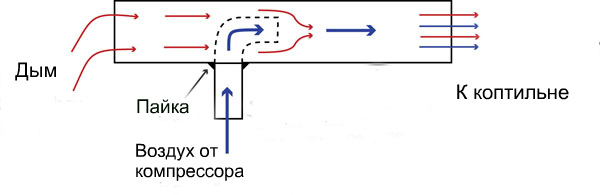

The smoke generator circuit is simple. So that you understand what is at stake, take a look at the photo below. It clearly shows how this device works.

It turns out that between the chamber of the smokehouse, where the firewood is smoldering, and the chamber in which the meat products are hung, a small cylindrical device is installed. A branch pipe with a branch inside is soldered into it, through which air is supplied under low pressure. Creating a stream moving towards the second chamber of the smokehouse, the air pulls along with it the smoke from the combustion chamber of the smoke generator. In this case, the smoke is completely absorbed, without remaining on the walls and without leaving the combustion chamber. That is, it is the most efficient form of smoke consumption, practically without losses.

So here is a combustion chamber with an intermediate element, which creates a directed flow of a mixture of air with smoke, and is a smoke generator. It is clear that the larger the combustion chamber, the longer the smoking process will take. If we talk about household installations, then for this you can use various household items. For example, an aluminum milk can, a used fire extinguisher, an old broken thermos. But the optimal solution is a smoke generator for cold smoking from a steel pipe with a diameter of 80-100 mm and a length of half a meter.

On the one hand, it is tightly closed with a lid, this is done by welding. On the other hand, it is left open, only a half-hole (round, rectangular) is made on the side, which will be used to ignite wood chips. A hole is also made on the side, to which a branch pipe is connected. Air will be driven through it. By the way, to create a directed air flow under pressure, you will need to purchase an air compressor. For example, the one used in aquariums. Here is such an uncomplicated smoke generator device.

Now, regarding the location of this branch pipe. It should be closer to the fuel combustion zone or vice versa. The best option is if the branch pipe is higher, that is, away from the combustion zone. The thing is that with a reverse installation, several negative actions occur.

- First, the height of the combustion chamber is limited. And this is the direct reason for the damping of firewood.

- Secondly, intensive smoke extraction leads to rapid fuel combustion, which reduces the life of the smoke generator.

- Thirdly, the draft inside the smoker is reduced, especially when the compressor is off.

- Fourthly, the low fit of the nozzle creates conditions under which unburned chips get inside. And this blocks the passage.

- Fifthly, low fit is the location of the nozzle in a high temperature zone, which reduces its service life.

The intermediate element of the smokehouse, which is also part of the smoke generator, can be made from ordinary pipes with a diameter of 20-25 mm. You can simply weld it to the combustion chamber of the smoke generator and to the smokehouse chamber, and in the gap install a branch pipe from the same pipe to which a pipe of a smaller diameter is welded. Through it, air from the compressor will be supplied to the smoke generator.

In principle, the intermediate part can be made in different ways. Here are just some of the variations:

- A connection of two pipes is made with a thread, where a fitting in the form of a tee is installed between them. A squeegee is inserted into its free hole, onto which the adapter from the pipe to the hose is screwed. Through the connected hose, air will be supplied to the smoke generator.

- Instead of a hose, you can solder a copper tube.

- Install a tee fitting on top of the combustion chamber using the installed squeegee. One side of the fitting will be directed into the chamber where the products are hung, the other will be supplied with air.

Some modifications of such a connection are shown in the photo below.

By the way, the method of attaching the nozzles to the combustion chamber of a smoke generator for a cold-smoked smokehouse, made by hand, can be done not only by welding or soldering. The same photo clearly shows the threaded mount. That is, there are many options for how to make a smoke generator. But the device made correctly will serve faithfully for many years.

Smoke generator compressor

As mentioned above, an aquarium compressor can be used to supply air to the smoke generator. This is a small device of low power (4-5 W), which is quite enough for the smoking household unit to work efficiently.

But the craftsmen do not stop at the same place. Save so save. Here's how you can make one of the types of compressors for a smoke generator with your own hands. To do this, you need a computer fan and a five-liter plastic bottle.

- The bottom of the bottle is cut off.

- A fan is inserted into the resulting hole, which is fixed with self-tapping screws.

- A hose is attached to the bottle cap through the cut hole.

- The fan is connected to the electric current network.

Simple and effective solution. The main thing is to ensure the sealing of all joints.

In principle, this is all that concerns such an apparatus as a smoke generator for smoking, made by hand. There is only one question left, how to smoke meat and fish products.

Firewood for smoking

There is only one limitation on the choice of firewood for the smoke generator. Do not use softwood chips for smoking. They contain resin, which gives the meat a bitter taste. All other tree species can be used without restriction.

As for the size, there are no prohibitions here either. The only thing you need to pay attention to is the ability to move the smoke through the laid and smoldering pieces of wood. Therefore, when small chips are put into the smoke generator, it is recommended to install an additional element inside the device, along which the smoke will freely move towards the outlet. It can be a perforated tube or a spring of the required length and width. Smoke will move between large chips on its own.

A homemade smoke generator is an efficient thing to work with and not costly for the budget. It is easy to assemble and maintain. The device has gained popularity since its inception, since smokehouses often require a separate space, and a smoke generator for cold smoking is mobile and compact, which makes it easy to place it on the smallest piece of land.

The unit is easy to operate - the principle is based on air movement. For example, a melted stove emits smoke into the chimney, the wind carries it to a certain distance - this device also performs its work.

Smoke generator

Self assembly

Today, in specialized stores for tourism and recreation, you can easily purchase a smoke generator for cold smoking, but making it yourself will be more practical and economical. The main components of any device that is intended for the production of smoke and subsequent smoking is a fire source necessary to maintain a certain temperature, as well as a cooling system and smoke supply to the chamber where the product is smoked.

It is important to remember that the process of assembling a smoke generator with your own hands is not complicated, but a responsible approach is necessary for the device to be an effective and complete addition to the smokehouse. At the very beginning of the work, it is necessary to find out what will be the source of heat - wood, electricity or gas. If we are talking about an option for use in urban conditions, then electricity will become the basis, and for dacha use, you can mount a firebox on wood - this will maximize the taste of the finished dish.

Design features of a smoke generator for cold smoking

You can assemble a homemade smoke generator using any design - there are practically no restrictions. It is important to take care of the presence of 3 components:

- Combustion chambers;

- Oxygen pumps.

Components are readily available and inexpensive

The combustion chamber is a container, the main part of the entire structure. Its shape and size can be different, it is only important that the materials are refractory. According to practical observations, the most optimal option for manufacturing a combustion chamber is to use a metal pipe with a diameter of 10 cm.

When doing the installation with your own hands, it is necessary to ensure that there is a hole with a diameter of 7-10 mm in the lower part of the container.

It is required to ignite and supply oxygen, as well as to constantly maintain combustion. The upper part must be closed in order to restrict the flow of air. For this purpose, a cover from the same pipe is perfect:

A plug is welded to a small piece of pipe and small strips are cut, the length of which is equal to the length of the side of the pipe. Strips around the perimeter can be welded or riveted so that they protrude beyond the edge of the future cover

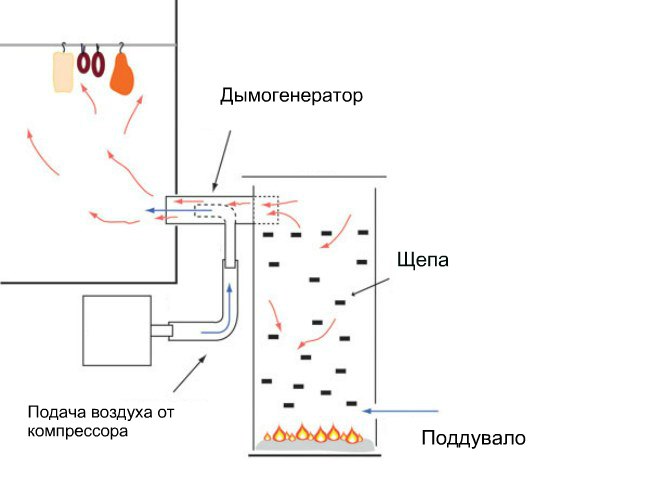

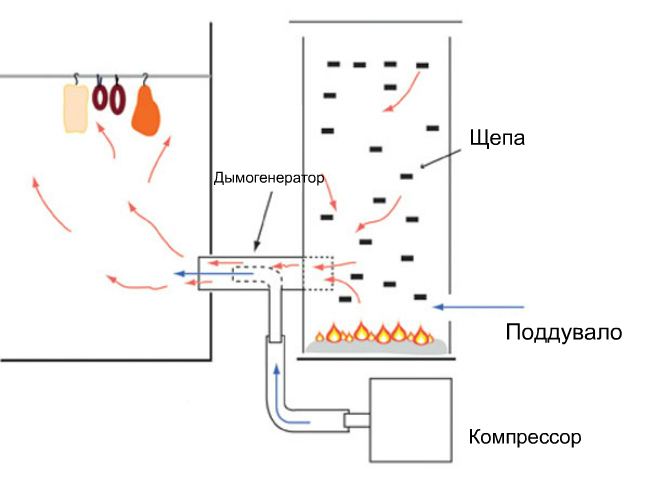

The main part of the structure - an ejector, is made from ordinary water supply "tees"; in addition, squeegees and pipes are required, which are connected to each other by welding or ordinary thread. Its location is not important - it can be installed both above and below.

Smoke generator for cold smoking with bottom ejector

This solution is ideal for a compact smokehouse. The device does an excellent job in conjunction with it, but due to its small size, it does not allow a sufficient volume of air to flow, as a result of which it quickly goes out. A self-assembled combustion chamber must necessarily include a pipe protected from chips from entering.

It is important to take into account that the ejector located in the lower part of the combustion chamber does not contribute to the process of natural air flow; such smokehouses need constant temperature control from the side of the person. If the ejector is located in the upper part, then all the difficulties and defects in the design of the smokehouse will immediately disappear.

Drilling holes Fixing fittings

Self-assembly features

The pump is necessary for the constant supply of air to the device. For do-it-yourself installation, an ordinary aquarium compressor may well be suitable, since its power is quite enough for such a design.

An aquarium pump is perfect for supplying smoke.

However, a home-made smoke generator for cold smoking can be a real masterpiece of human thought, since an old cooler or a home fan can act as a source of air pumping. You just need to connect the air source with a plastic bottle and the element can be considered successfully assembled and ready for use.

A compressor can be made from a cooler and a bottle

A self-assembled smoking device differs in that any wood is suitable as fuel, unless you have to give up spruce and pine, since they are sources of resins that are harmful to the smokehouse and distort the taste and smell of the finished dish. The size of the chips is not so important, but it requires attention, because when using small sawdust, it will be necessary to make a small addition to the design - use a spring that will serve as a kind of chimney, allowing the smoke to pass through the layer of sawdust.

The smoke temperature of the smokehouse is important for the final result, since not only the appearance of the product and the aroma depends on it, but also the degree of readiness.

In most generators, the temperature can be adjusted at will - by increasing or decreasing the length of the pipe that connects the smoking chamber directly to the smoke generator.

As the main smokehouse, you can use an empty gas cylinder or a metal barrel, even a box or box is allowed. Many have adapted old, non-working refrigerators for cold smoking, since they are tightly closed and well insulated, which allows them to maintain a constant and optimal temperature.

Thus, it is not difficult to create a functional smoke generator for cold smoking with your own hands. You only need a little free time and creative thinking, since you can create a device from almost any materials at hand.

If there are no suitable materials or tools, try making a cold smoking smoke generator like in the video.

Smoking requires not only the correct choice of processing technology for certain food products, but also requires special equipment. In this article, we will consider with our own hands, drawings, accessories, installation operations. After studying this information, it will not be difficult to make a design exactly according to individual needs.

Read in the article

Basic information

Smoke treatment has been used for hundreds of years. It prevents the decomposition of organic matter, prolongs the shelf life of food. Mushrooms, meat, fish after the appropriate procedure acquire a specific pleasant taste.

Unfortunately, some of the achievements of modern science are not used for the benefit of consumers. With the help of skillfully selected chemical compounds, the appearance and taste parameters of smoked products are imitated. We can only hope that the ingredients in Liquid Smoke are really harmless. A homemade smoke generator will help to eliminate unnecessary risks. Its parameters are not difficult to select in exact accordance with the existing requests for the volume of processed raw materials.

Features of culinary processing

In practice, two methods are used. Hot smoking uses a temperature range from + 55 ° C to + 110 ° C. The main advantage is the speed of creating ready-to-eat products. However, this processing cannot be called gentle. Excessively high temperatures can destroy vitamins and other beneficial compounds. An uneven effect on the entire volume is permissible, therefore, a marriage is possible. The shelf life of finished products is shorter than with cold smoking.

To reproduce the second technique, the equipment presented in this article is used. With its help, smoke treatment is carried out in a gentle mode (from + 25 ° C to + 30 ° C). If in the first variant the duration of the procedure is several hours, then here it will take days. But the finished product will contain many useful ingredients. Its shelf life will increase.

Important! Smoke generators for cold and hot smoking are different devices. In this case, it is necessary to lower the temperature of the combustion products to the optimal level.

For your information! Smoke is created using smoldering wood. Only hardwoods that do not contain resin are used for smoking. Apple, cherry or pear have particularly pleasant aroma characteristics. But such raw materials are difficult to find. More common trees are suitable: willow, alder.

Formulation of requirements

To select the appropriate option, it is necessary to use the stated data on cold smoking technology. It is also necessary to take into account the limited technical and financial capabilities of the average person. Using these factors, it is not difficult to formulate hardware requirements:

- The device must generate high intensity smoke.

- It must be continuously fed into the working chamber with cooling to an acceptable temperature.

- Convenient if the operation of the installation does not need to be monitored. But at the same time, one should remember about the need to comply with elementary fire safety rules.

- The chips are inexpensive. But the fullest possible use of such fuel will come in handy. This will allow, with a reasonable size of the generator, to increase the interval between downloads.

- The more complex, the less reliable the designs. It is necessary to choose a smoke generator that is simple enough to create at home, well adapted for long-term operation.

Important! If you decide to buy a smoke generator for cold smoking, the price will only be one of the important factors. You should pay attention to the requirements given in this section in order to select quality equipment without errors.

smoke generator for cold smoking

Features of the device of a smoke generator for cold smoking with your own hands

A simple design consists of the following components:

- Capacity. A layer of sawdust is placed on its bottom. A removable cover is used for refueling. In the lower part there is an ignition hole.

- Air supply hose. It is installed at the top of the case.

- In the same place, but on the other hand, the outlet branch pipe is mounted. The smoke from it enters the working chamber.

- Air blower.

Each of the installation methods has certain advantages and disadvantages:

- The upper one is removed from the smoldering area, so the node is not exposed to unnecessary thermal effects. Here, the smoke is cleared by a backfill layer and cooled by a longer path.

- Bottom mounting is convenient for quick replenishment of sawdust stock. In this case, no significant obstacles are created to the free passage of smoke. In the first case, when using raw materials from too small fractions, a decrease in productivity is not excluded.

How to make a smoke generator for cold smoking with your own hands: drawings and proper preparation

The project should be studied as a whole so that the created product is convenient to use, and the characteristics of the smoke correspond to the optimal parameters. Therefore, first you need to correctly determine the place in which the smokehouse will be installed. It is necessary to provide free access to all its parts. It will come in handy on which you can lay out and pack food.

The figure shows that cooling is performed in a long channel. The smoke generator is located at the bottom, so the heated air rises on its own. The clear advantage of this solution is its autonomy. It was used by our ancestors who did not know electricity. But even today, if you have your own, you can implement a similar project. The equipment will perform its functions economically, without consuming electricity.

Such large-scale structures are created on the basis of a special engineering project. They are used for the production of food products in commercial quantities. Ordinary household tasks will be successfully solved with less cost.

Features that are important to consumers are highlighted below:

- The device shown in the illustration is mobile. It can be connected to different smokehouses, transported, stored without unnecessary difficulties.

- It does not need an additional source of energy. Ignition and air access - through a hole with a diameter of 10 mm in the lower part of the case.

- Removing the bottom will make it easier to remove the ash.

- Special wing nuts are not only fasteners. Their shape makes it easy to securely fix the structure on the ground.

- The purpose of the remaining elements is clear from the drawing. It should be noted that the dimensions are working. But they are optional. If necessary, the future user has the right to make his own adjustments.

smoke generator for cold smoking

Important! When the ejector is located at the top, it is necessary to ensure sufficient free passage of smoke through the compacted layer of sawdust. To do this, use a metal spiral, or a perforated tube.

To cool the smoke, the length of the pipe from the generator to the smokehouse is increased. The following figure shows an example of a more advanced system.

An electric heater with a regulator (1) is used here. Smoke is drawn off at the top. As it passes through the coil (2), it cools down. The next block acts as a filter. Moisture builds up at the bottom. For subsequent removal, use the built-in valve (3). Above - mounted analog (4).

Important! By installing the coil in running water, the cooling will be even more intense.

An aquarium compressor is often used to supply air to the ejector. This specialized technique has sufficient performance. It is designed for long-term unattended operation. Minimal noise and reasonable cost should also be noted as positive characteristics.

When making such structures on your own, you need to choose suitable component parts. Computer fans work well. They are able to perform their functions for a long time without breakdowns.

Making a smoke generator with your own hands for cold smoking: video and text instructions

For the manufacture of the main part of the structure, you can use the drawings that were presented earlier. The following tips will help you build without errors:

- A wall thickness of more than 2.5 mm is chosen for the walls of the steel body to prevent deformation under strong heating.

- Since the temperature in the upper part will not be high, it is permissible to use a flexible hose to connect the compressor. The boss can be made from Teflon. It functions as an insulator and a connecting element. Tubes of appropriate sizes are inserted into it.

- The bottom does not have to be removable. If desired, create a wide opening with a closing door. Ash is extracted through it. Traction is adjusted by moving the damper. This option is used with a large case size.

- The top cover should close tightly.

- Everyone cleans up. To prevent the appearance of rust, the outside of the case is covered with and. These compounds must be resistant to high temperatures.

- After assembling and connecting the compressor, the container is filled with sawdust and the operability of the device is checked.

Smoke plays the main role in smoking, as it processes the products in the smoking chamber. The taste and richness of the aroma depend on its quality and concentration. To establish an ideal cold smoking process, you need a smoke generating unit that can be made at home, but for this you need to know how a cold smoking smoke generator works and what basic structural elements it consists of.

Purpose and principle of operation of smoke generating units

The purpose of the cold smoking smoke generator is to produce a large amount of smoke and supply it to the cabinet for the preparation of smoked meats. As a result of interaction with semi-finished products suspended in the smoking chamber, chemical reactions occur that turn the pickled meat (fish) into a product suitable for consumption.

The principle of operation is based on the supply of smoke to the smoke chamber through the chimney. Dry chips (sold in a store or made independently) are placed in the body, the average consumption of which is 100 g per 1 hour of cold smoking.

Smoldering rate depends on moisture content, wood species and chip size

After loading the chips, working elements such as an air duct and a compressor are attached to the body, after which the fuel is ignited.

The design of the smoke generator is of two types:

- Top-mounted ejector;

- With the bottom location of the ejector.

An illustrative diagram of the differences is shown in the drawing below.

Ejector - a device that provides a flow of smoke into the smoking chamber. The principle of the ejector is as follows: the flow of one medium (in this case, air) in the tube creates a vacuum, which provides flow and thrust for the other medium (smoke). For a visual representation of the ejection principle, see the schematic drawing below.

It is considered the most convenient in operation with the upper location of the ejector, when the direction of air supply from the compressor coincides with the natural draft. If the compressor stops working, the chips will not stop smoldering. In addition, the upper location of the ejector ensures the autonomous operation of the apparatus.

The main structural elements of the smoke generator

The device of a smoke generator for smoking is not a complex system and consists of the following elements:

- Frame - capacity of a cylindrical or square profile. The best material is stainless steel, but there are aggregates made from other metals and alloys. The purpose of the body is storage of chips for and the place of smoldering itself

The following can be used as a body: a pipe, a thermos, namely its internal capacity, a fire extinguisher, etc. The optimal dimensions of the body are: 10 cm in width and 40-50 cm in height.

For slow smoldering of sawdust, it is desirable to produce dense stacking of sawdust, which were previously prepared. Moderate supply of air, both to the ejector and to the wood waste smoldering zone, will also help to reduce combustion. .

- Chimney ... Fastened to the body and ensures the removal of the smoke mixture from the ejector into the smoking chamber. Reliable fixation of the element to the body is ensured by a welded seam or a threaded connection;

- Ejector as a tool for creating good traction;

- Compressor ... A do-it-yourself smoke generator for cold smoking must have a means to improve traction and mix air with the generated smoke inside the body, that is, an ejector. And, in turn, a conventional compressor for small aquariums (up to 6 l / min) with the option of adjusting the air supply is perfect for powering the ejector. It connects to the ejector air supply connection.

It is allowed to use home-made compressors from plastic bottles and a cooler from a computer.

How to use a smoke generator for smoking

- The smoke generating unit is installed opposite the smoking cabinet on a flat surface, in which a hole is made in advance at the level of the chimney;

- A flexible hose from the aquarium pump is connected to the ejector connection;

- The body is tightly covered with chips (up to 1 kg);

- After loading, the lid closes tightly. If necessary, you can use a heat-resistant sealing gasket to seal the joint;

- Setting fire to sawdust with a lighter or gas burner;

- As the fuel burns out, the smoke generator body is re-filled with chips

- The smoke supply is regulated by adjusting the air supply by the compressor and the damper on the body.

- If necessary to control the temperature, the probe of an electronic thermometer is placed in the smoking chamber.

A little about smoking chambers

A do-it-yourself smoking chamber is a container or smoking compartment in which the stored products are prepared using smoke. Since we are talking about smoke generators, the chamber is not equipped with a portable oven made of metal or brick. It represents a mobile device located on a horizontal surface, above the smoke generating device when the ejector is located at the top, or parallel, at the bottom.

Depending on the volume of the smoking chamber, future delicacies are arranged in one or more rows.

Safety measures when working with a smoke generator

The device of a smoke generator for cold smoking is not included in the category of fire hazardous units, but it is necessary to observe safety measures, since during operation smoke is generated and an electric compressor is used:

- Turn on the exhaust device if the smoke generator is operating in a residential area;

- Install the device on a horizontal surface;

- If wood chips are ignited, use a spray bottle with water;

- When a characteristic burning smell appears from the compressor, it will turn off the device;

- Wear gloves when servicing the device in working order.