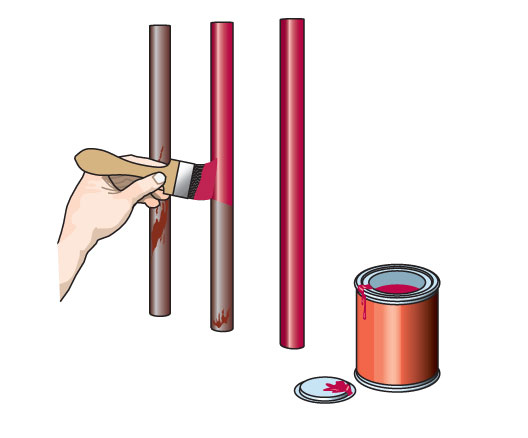

It is usually necessary to remove the loose layer of rust and peeling paint from forged products that have already been used, especially those that are located in the open air. For such cleaning, the most suitable tool is selected:

- Wire wire brush

- Coarse sandpaper

- Grinder

- If metal products and a lot (fence, ), then it would be more rational to purchase sandblasting machine. Sanding will save time and effort.

Now you need to brush off the dust and remaining sand and start degreasing.

Cleaning new forged products is different. Factory grease, grease and oil stains may remain on ferrous metal. They are washed off with a 5% solution of any SMS (synthetic detergent - washing powder) or removed with a solvent. Shiny and smooth metal is treated with sandpaper P-40 or higher, and dust is removed. Galvanized surfaces are washed with a stream of water, but aluminum and its alloys do not require preliminary cleaning - they are simply degreased immediately.

Methods for degreasing forged elements

- Hot water-soap solution (90°C) - to prevent the soap from curdling, first boil the water, then dissolve the grated laundry soap

- Caustic soda solution is also very hot

- Various solvents - acetone, isopropanol, 646, butyl acetate, etc. (before painting there should be no traces of solvent left on the metal)

When working with chemicals should be protected open areas body with gloves, masks, goggles and do not touch fat-free surfaces.

The traditional painting option includes several coating stages:

- Rust converter— after applying the composition it turns into a durable chemically neutral coating, enhancing the anti-corrosion effect of the primer

- Special primer composition— stops the formation of rust, isolates from moisture, gives high adhesion to metal and subsequent coating. Typically the primer has weak decorative properties and wear resistance. Although primer-enamels are produced “two in one” - corrosion protection plus an attractive appearance of the product. When choosing a primer, you should pay attention to the label: most of them are universal, but there are only for interior or only for exterior use.

- Paint for forged products(for metal) - decorative coating, which is applied over the primer layer and protects it from aggressive influences environment: precipitation, sunlight, temperature changes. To enhance protection and extend the service life of paints, special varnishes are sometimes applied as an additional layer.

Modern developments in the field paint and varnish materials allow you to combine the properties of all layers. For example, rust-converting substances are added to the soil, and anti-corrosion components are added to the paint. Thus, special forge paints not only give forged products expressiveness for many years, they have increased performance characteristics and protection against corrosion.

Painting – adds sophistication to durability.

On video: painted wrought iron railings

Making and installing gates is only half the battle. So that they last for a long time and have not been negatively affected by precipitation, corrosion, etc., it is extremely important to choose high-quality paint. The paint for the gate must match modern standards quality, because on the street she faces serious negative impact, this includes frost, rain, snow, ultraviolet rays and the like.

In this article, we will tell you how to paint a gate and what paint to use. By doing all the work correctly, as well as choosing the appropriate composition, you will be able to provide reliable protection to your manufactured gates for many years. In the photos and videos in this article, you will see clearly how to do all the work yourself.

How to choose the right one

Today there is a wide variety paint and varnish compositions that it offers modern market. You should figure out which one is better to choose. Therefore, before going to a specialized store, you should carefully study this issue.

The following types of compositions can be used to paint gates:

Considering the widespread use of hammer paint, let’s take a closer look at all the advantages. What exactly makes it so popular for painting gates?

Benefits of using hammer paint

This paint composition is great for painting gates and other outdoor elements. And there are significant explanations for this:

- There is no need for labor-intensive preparation work. The composition of the paint allows you to avoid cleaning the gate from rust and applying a primer.

- Painted gates will serve reliable protection for metal from exposure to ultraviolet rays and moisture.

- The surface of the gate acquires a dirt-repellent effect. As a result, the structure will not get so dirty.

- This paint gives the gate a beautiful appearance.

Advice! When purchasing hammer or other paint, you should pay attention to whether it is approved for outdoor use. It must reliably protect the structure from negative impact environment, as well as withstand frost, moisture, high temperature And so on.

When using hammer enamel, you should pay attention to the fact that its application to the surface of the gate is allowed only in sunny, warm weather. If it will be wet weather, that is, there is a risk that everything will have to be redone.

Primer for painting - which one to choose

Painting gates requires first applying a special primer to them. This increases the quality of adhesion. Also, applying a primer has a positive effect on external characteristics. When it comes to choosing a primer, it is preferable to trust the manufacturer of the gate paint you choose.

One of the advantages of using primers is that they contain substances that convert chemical composition rust. That is, this means that the process of metal oxidation slows down significantly. The use of special primers will extend the service life coverings.

Paint application technology

Having decided on the choice of paint for the gate, you should pay special attention to how to paint it correctly. The technology itself is very simple. However, there are some details and nuances that are important to consider when working. Moreover, a certain sequence should be followed.

To carry out the work you may need the following tools and materials:

- Dye.

- Primer.

- Sandpaper.

- Roller.

- Brushes of different sizes.

- Solvent.

All work consists of the following stages:

- Preparing the gate surface.

- Eliminates grease, dirt, rust and other contaminants.

- Applying primer.

- Painting the gate.

Now let's look at each stage in its own sequence.

Preparation

First of all, all preparatory work should be done. To do this, the gates are cleaned of all kinds of contaminants. Everything is much simpler if you have a new gate. It’s enough to clean the gate thoroughly and that’s it. As for the old gates, there is much more trouble. For example, it may be necessary to remove the old coating. To do this, you can use special compositions, which are called “Paint Removers”.

It is also important to degrease the surface. Due to this, the quality of adhesion increases significantly. If you find areas with identified rust, then you need to use sandpaper or a grinder with a grinding wheel. If you made the gate yourself, then before painting you should also carefully sand everything welds. Then take a garden hose and, under strong pressure, wash off all possible dirt from the surface of the gate. It would be a good idea to wash their surface with special detergents. This way you can remove all dirt and possible grease stains. After all this, let the gate dry thoroughly.

Advice! Remember that in order for the paint to adhere well, you should thoroughly wash the gate from grease. To do this, wash each corner of the gate with a special cleaning brush. Moreover, remove all stubborn rust.

Applying primer

The next step is to start applying the primer. It's very easy to apply. To do this, you can use a regular brush or roller. It is recommended to use a rust converter first. After applying it and drying, it will appear on top of the surface. white coating. You can remove it with a regular rag. Only after this can the primer be applied.

When applying primer, you should reliably protect all structural elements from getting it on them. For example, you can buy a special masking tape and paste it over door handle, awnings or others important elements. The primer is applied using a sprayer or a regular brush. You can also prime the gate using a roller. This method of painting gates will significantly speed up the whole job.

Advice! The primer should be applied at least 10 hours after washing the gate. During this period, all moisture will completely evaporate.

As for the number of layers of primer, one cannot do it. To achieve the best result, apply the primer in two or even three layers. The only thing that is important to take into account is that you apply each subsequent layer after the previous one has completely dried.

Applying paint - the final touch

Most final stage consists of painting the gate with paint. Remember that you should start with it only after the primer has completely dried. You can apply paint to the gate with a brush. However, in this case, stains may remain on the surface. To ensure that the paint is evenly distributed over the entire surface, it is better to use a special paint roller.

Painting should begin from top to bottom. While working, make sure to completely avoid the possibility of drips. When using a roller, this probability is very low. To make sure you don't miss anything, take a few steps back and see how you do. To achieve the best result, apply the paint in two layers. If necessary, three layers can be applied, but this is done extremely rarely.

For painting individual elements such as awnings, gate ends and the like cannot be done without using a brush. Therefore, during the painting process you should combine the use of tools. Moreover, it is necessary to apply a second layer of enamel after the previous one has completely dried. This is an important condition.

Conclusion

So, we have reviewed with you all the features of the process of painting gates, as well as the choice suitable paint. This article offers many photos that show how to carry out certain work processes. Be careful, because doing this kind of work can get pretty dirty. Therefore, wear old or work clothes. Be sure to wear gloves on your hands. If paint gets on exposed skin, use a solvent and remove it immediately after completing all work.

Why is there a need to paint metal products and why do it at all? After all, this is a strong and hard-to-wear material, and, for example, new garage metal gates already painted. Is it really just for beauty? Answering these questions is required to understand actions to preserve metal products from corrosion.

Determining the need for staining

Metal gates country house, both garages and entrances are used daily, which is necessarily reflected in their canvas. Moreover, they are installed on the street. And metal structures located in the open air are affected by temperature and humidity, ultimately leading to corrosion of the product.

The rust-corroded canvas gives the gate an unaesthetic appearance. This indicates not only the influence natural factors, but also about improper preparation of the surface for painting. Therefore, it is necessary to pay attention to the process of preparing and painting metal products.

The need for painting is determined visually. This is not only clearly visible rust, but also the presence of internal corrosion, which leads to the appearance of small bubbles on the surface and further peeling, as well as peeling of the paint. If the preparatory work is done efficiently, then the next painting will not be required soon. It will only be necessary to periodically tint, or rather, refresh.

Paint selection

When choosing a material for exterior work, you should be guided by certain requirements. They are dictated by the need for a long period of preservation of the surface from external factors. Here are the properties that the selected paints and varnishes should have:

- good ability to adhere to the surface (adhesion);

- sufficient elasticity, since expansion and contraction are the response of metal products to temperature effects;

- presence of water-repellent properties;

- possibility of use in a wide temperature range;

- resistance to chemically active substances;

- strength under mechanical stress.

When choosing a paint and varnish product, it is necessary to take into account all the points on this list. After all, iron gates are used in different conditions. They may be affected not only by temperature and moisture, but also by mechanical forces or accidental ingress of oils and other chemicals.

Knowing the requirements for paints for outdoor work, you can proceed directly to the choice. There is a wide variety on sale paint and varnish products, the cost of which varies widely.

The most used types are the following:

- Nitro paint is quick-drying, making it easy to use. However, it peels off and then, within six months, peels off. Not recommended for use over other types of paints and varnishes.

- Oily. Allows you to cover the product with a thick layer, but takes a long time to dry. Depending on the company producing the product, the drying process can last from a day to a week. Over such a long period of time, small particles stick to the canvas, which reduces the attractiveness of this type of paint.

- Alkyd enamel is universal and has good abrasion resistance. There is a wide range color solutions and the ability to choose textures - regular glossy or matte. The durability of the painted surface is from 3 to 7 years. Drying time is within 24 hours.

- Acrylic enamel - withstands sudden temperature changes and exposure to moisture, as well as aggressive substances, and is elastic. It has become widely used.

- Organosilicon enamel has good adhesion, is durable and elastic. It is especially noted for its heat resistance, anti-corrosion properties and low consumption when painting.

Choosing a painting tool

This is an important point in production painting works. The right approach is needed to preparatory work, and to painting the gates. Which tool to choose - independent process, depending on specific conditions and circumstances. An important factor here is professional level producer of the work.

A roller, a brush and a spray gun are the tools necessary to complete the work. Painting only with a brush is ineffective due to the appearance of streaks on the working surface. The work will have to be done again. It is impossible to paint with a roller in corners and narrow places. Therefore, their combined use is recommended.

The spray gun can only be used by a person who is skilled in working with it. It is required not only to change the spray pressure in a timely manner, but also to know what viscosity the paint must have in order to paint the gate. Lack of skills will lead to strong drips throughout the entire area to be painted.

Preparatory work

Preparation for painting the gate must be carried out in strict sequence. The following work steps must be completed:

- Washing or cleaning from dirt. Contaminants are removed, as well as other substances adhering to the canvas are washed away. The most thorough work can be done using a hose. Pay special attention to corners and hard-to-reach places.

- Surface cleaning. At this stage, it is necessary to remove peeling paint from the canvas. If the layer of the previous coating is large, then the entire thickness of the old paints must be removed. The work can be done either with a metal brush or with a hair dryer. It is possible to use a grinder or a drill with a special attachment – a “brush”.

- Grinding. Produced sandpaper fine-grained structure, regardless of the method of doing the work - manually or using a drill that has a special attachment. The mechanized method speeds up the work. However, without using manual grinding can't do without hard to reach places Oh.

- Degreasing. Performed with a solvent after cleaning and sanding. It is important to treat the entire surface without gaps, not forgetting hard-to-reach areas. The quality of adhesion of further coatings to metal depends on this.

Of course, changes and additions to the work order are possible. Some gate owners wash them after cleaning and polishing, using detergents. This allows you to save on degreasing products. But it should be remembered that these works must be carried out especially carefully, and detergents cannot replace the solvent.

Carrying out painting work

The best way to paint evenly is with a spray bottle. The work is done quickly and efficiently, with all hard-to-reach places painted. Be careful not to get into Airways small drops of paint that fly in the form of a suspension in the surrounding space when performing work with such a tool.

The most common way to paint is to use a roller to large areas, and the brush is in hard-to-reach places.

Painting work must be done from above, gradually moving down. Apply paint in parallel lines that overlap by several centimeters.

After painting is completed, it is necessary to evaluate the integrity of the work. To do this, step back a few meters to identify gaps and other defects. Paint over the discovered areas with a brush. If the paint color turns dull after drying, a second coat is required. The work is performed in the same sequence - from top to bottom. It is possible to apply several layers to achieve bright color

surface to be painted.

Metal forging has always been considered a difficult and revered art. It is precisely art, since it is one thing to simply weld two pieces of iron to each other, and quite another to make something beautiful and pleasing to the eye out of it.

But to create a real masterpiece, the skill of one blacksmith is not enough, the finished product still needs to be painted, and we will talk about how and what is the best way to do this in this article. Someone might say that painting a forged product is no different from painting, for example, wooden table top , but this is far from the case. Firstly, these are, of course, special paints, which will be discussed below. And secondly, the method of painting, especially if there is a need to perform Painting works

with your own hands, but there are no skills in this matter.

It is interesting that if the approach is incorrect, even the most expensive and high-quality paint will be powerless to protect the product from corrosion.

- If we talk about painting methods, they can be very diverse:

- Brush.

- Spray gun (see Selecting a spray gun for painting).

- Tampon.

Important! When working with a spray gun, you should remember that the thicker the consistency of the paint, the harder it is for him to spray it and the higher the pressure must be set on the compressor.

But you should always remember difficult places, which are on forged products always in excess. For example, these could be welding points, the fact is that during the forging process, the metal is subjected to strong heating and weakens on its own, and welding burns even more protective film, which always forms on the surface.

It is at the welding points that corrosion begins first, and from there it spreads throughout the entire product. Another important nuance, which should be remembered is cleaning the product, no, not from possible rust, since three-in-one paint for forged products can handle it safely, but to clean it from scale and delamination of the metal.

Product cleaned and prepared for painting

The fact is that at the moment of calcination, non-uniform parts of the metal begin to peel off; during a cursory examination this may not be noticed, but it is enough to finished product wire brush, as particles resembling scales immediately begin to fall off.

Cleaning with a wire brush must also be done if the product has already been painted and now you just need to renew the coating. Metal paint has very high adhesion to the surface being painted, but it can peel off from the old coating.

Forging paints

Playing on color contrast, looks perfect on wrought iron gates

If the question of how to paint forged products yourself is more or less clear, then what paints to use is a much more complex and extensive question. If you do not pay due attention to it, then the product will have to be repainted annually, especially if it is located outside.

Today, there are a lot of paints specialized for metal (see Types of paints for metal: which one to choose), and each of them has its own unique set of qualities, and such diversity only confuses the inexperienced person even more. We will not dwell on the entire assortment presented in modern construction stores.

And let's talk only about the most popular and, as a result, quality materials, designed specifically for metal surfaces, taking into account the fact that the product will be used outdoors and constantly exposed to negative influences.

Hammer paint

Hammer paint, or paint with a hammer effect (see Paint with a hammer effect: features of use) is so named for the similarity of the coating to potholes caused by hitting metal with a hammer. Relief surface paint perfectly hides all the small imperfections and flaws that inevitably happen on a forged product, especially if we are talking about a real one hand forged, and not about stamping on machines. The instructions for applying hammer paint assume using any convenient tool.

It can be:

- Spray gun.

- Roller.

- Brush.

- Tampon.

It all depends on personal skills and preferences; the quality of the coating will not suffer at all.

Important! Hammer paint is very thick, and even the working consistency of the material may not lend itself to simple electric spray gun. Therefore, if it is not possible to use a compressor or pneumatic tool, then it is better to use simpler and more accessible methods.

Pros:

- High degree of adhesion to metal.

- Three-component paint does not require an additional layer of primer.

- The polymer coating is completely resistant to water and sunlight.

- Durability. A product coated with hammer paint does not need to be renewed for many years.

- Large selection of colors.

- High resistance to mechanical damage. Hammer coating very difficult to damage, even with heavy or sharp objects.

Unfortunately, even this material has several disadvantages that must be taken into account when choosing hammer paint as a coating.

Minuses:

- The relatively high price, which, however, is more than compensated by the durability of the paint.

- High paint consumption square meter, especially when working with a spray gun.

- If repainting is necessary, hammer enamel is very difficult to remove, and no other coating can be placed on top of it.

- Hammer paint is available in a very wide range color scheme, but despite this, if the required shade is not selected, it is not possible to use color paste.

As you can see, the disadvantages of hammer paint are less significant and are fully compensated by the advantages, but they exist, and this imposes a number of restrictions on the use of this material.

Forge paint

In the photo, a special solvent for blacksmith paint

Painting forged products with blacksmith enamels is considered the most durable and high-quality. Today, only a few European companies produce paint of this quality, and accordingly the cost of this material is simply sky-high.

But considering that the manufacturer himself gives the minimum guarantee period for their products are over 25 years old, then the price becomes much more attractive. The peculiarity of this paint is that it consists of stable polymers, and in appearance it may resemble ordinary bitumen, but this is not so, forge enamels are not only much more stable than mastic, but also have a shine characteristic only of oil dyes.

One more interesting feature Forge paint is that it dries very quickly even at sub-zero temperatures. This makes it possible to paint the product directly outside and not be afraid that the coating will be ruined by rain or unexpected frosts.

Even a well that is in constant contact with water can be painted with blacksmith enamels

If we talk about the minuses, then except high price, we can highlight the need for a mandatory preliminary layer of primer, which must be of the same brand as the paint itself. Otherwise, the manufacturer automatically withdraws all warranty obligations about the durability of the coating.

Interesting! If financial possibilities are limited, then you can simply use blacksmith’s primer and apply regular PF paint on top of it. In this case, all the characteristics of the enamel increase several times, although the result is unlikely to be achieved at 25 years.

And in order to clearly understand how to work correctly with blacksmith paints with your own hands, you can watch a video that clearly shows all the stages.

Paints ML

ML paints for car painting

Enamels under this brand - attempts domestic producers create a kind of hammer enamel. Unfortunately, their quality is significantly inferior to their foreign analogues, but their cost is also much lower.

Externally, this paint resembles a regular PF, but unlike it, it has higher technical characteristics, including durability and resistance to mechanical damage.