Putting tiles on the wall during the renovation process is, one might say, only half the battle. After all, various attributes of the room are hung on the walls: shelves, mirrors, and so on. And then the task for the manufacturer of works is how to drill a ceramic tile. It would seem that this is not the most difficult problem, but practice shows that not every home craftsman can cope with the task at hand.

The thing is that the tile is a very durable material, covered with glaze on the front side. The latter - the material is slippery, which complicates the drilling process itself. At the same time, the tile easily cracks when it is exposed to vibration and shock loads. Therefore, the likelihood that the lining will crack if the holes are drilled incorrectly is very high. Therefore, this process must be carried out carefully.

First of all, you need to choose a tool with which you will be drilling holes. Most often, drills and screwdrivers are used for this. In this case, it is necessary to choose such models that have several speed modes, because drilling the tile so that it does not crack is possible only at low speeds.

As for the drills for drilling ceramic tiles, none of them will work here. First, conventional metal or wood drills are made from simple tool steel. And their working edges are sharpened in a special way. Such glaze cannot be drilled. The technology of drilling in ceramics coated with durable glaze is based on the method of erasing the glazed layer using abrasive materials.

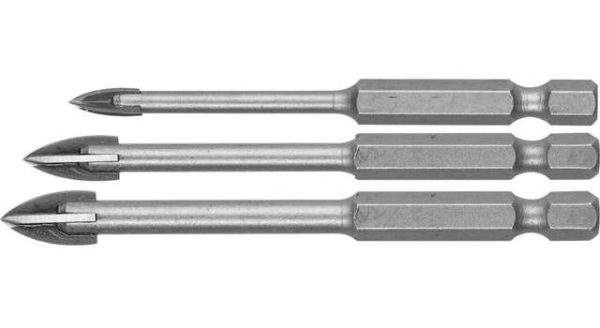

Tile drills

There are several types of drills that are specially made for drilling holes in ceramic, glass and porcelain. One of the varieties is a spear drill.

This tool is based on brass, that is, this is the material from which the tip is made. The latter is covered with diamond chips on top, and the tool itself undergoes heat treatment, during which the two materials are sintered together. The end result is a hard-wearing and very tough coating. The edge-mounted tungsten-titanium insert provides additional strength to the tool.

This is a rather expensive drill, so there is no need to buy it to drill multiple holes in a tile. A spear drill with a victorious tip is suitable for this. It is cheap, but with a minimal service life. Therefore, for making holes in tiles, for example, only in the bathroom and toilet, it will be just right.

The victorious drill is sharpened in a special shape that allows you to easily make holes in ceramic products. The main thing is not to pinch the tool during work. A sharp sharpening tool creates minimal contact with the tile, which allows the drill itself to easily enter the body of the tile.

If neither the first nor the second drill is at hand, then you can also use drills for concrete, which are made of hard alloy. It is optimal if this drill will be with a victorious tip. If not, it's best to use a new tool that hasn't been drilled yet. Sharp edges are the key to the quality of the final result. But keep in mind that it is necessary to make holes in the tiles with such a drill very carefully, because it is not intended for tiles.

Now to the question of what criteria still need to choose a drill.

- A kind of shank. For example, a cylindrical shank is best used in drills with low speeds, because they can slip inside the chuck at high spindle speeds. There are taper shanks and hex shanks. The latter are the best in this regard, moreover, they are more often used in cases where it is necessary to frequently change drills.

- Diameter. This indicator is the most important, because the diameter of the hole in the tile will depend on it. The size range of this indicator is quite large, where the maximum value is 12 mm.

- Length. This size depends on the thickness of the tile itself. Usually, drills with a length of 58 mm are used for this.

Tile drilling technology

So, let's move on to the main question of the article: how to properly drill a tile so that it does not crack. First of all, it is necessary to take into account some of the nuances of the drilling technology.

- The tile and drill must not overheat. This will immediately affect the outer decorative layer of the tile. It will simply crack, the end result is cracking of the facing material itself. Therefore, the advice is to wet the tiles while making the hole.

- You need to find the optimal pressure on the drill. This comes with experience, but you need to understand: created a little pressure - do not drill the tile, created a lot of effort - broke it.

- If you need to drill a hole between the tiles (in the seam), then this must be done very carefully. Therefore, the drill must be installed in the middle of the seam. If the hole on the markings fell from the edge of the tile, then the caution should be increased tenfold. There is a high probability that the tool will slide off the glazed surface towards the seam, and this can cause the edge of the tile to break. As a result, the tile itself may burst.

Attention! It is not possible to use the reverse mode when drilling a ceramic veneer.

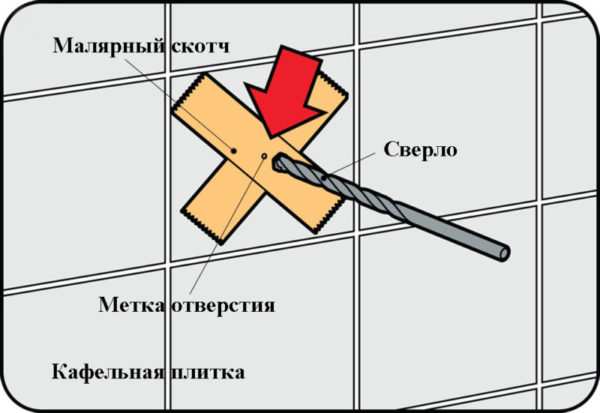

Before drilling the tile, you need to mark the drilling point with a marker. Then it is better to install an adhesive tape or plaster on the glazed surface. This material will prevent the drill bit from slipping off the smooth surface of the ceramic, making the process easier.

Please note that if the dowel, into which the self-tapping screw will be screwed, needs to be installed deep into the wall, then the tile and the wall itself will need to be drilled in two stages: first, the tile is drilled, then the drill is changed to a conventional one for concrete, with which the wall is drilled.

When drilling ceramic tiles, the hammer drill cannot be used. And for drilling the wall is already possible. After that, you can drive a plastic dowel into the drilled tile.

Large hole drilling technology

Typically, large holes are drilled in tiles for three reasons: for an outlet, for a mixer, or for a pipe. It should be noted that special crowns or ballerinas are used for this process. But there is an option for making a hole using drills. But everything is in order.

Crowns are cylindrical tools with a circular cross-section, the edges of which are covered with a hard material. It is by the coating-spraying that the cutters-crowns differ.

- Diamond. These are the highest quality tools with which you can cut not only ceramic tiles, but also porcelain stoneware. True, the latter results in rapid tool wear. It is recommended to use cooling when drilling holes, for example with water, which increases the speed of the drilling process and the life of the bit itself. It should be noted that, like all diamond tools, these bits are expensive items. And there is no need to use them to cut multiple tiles. For this, it is better to purchase other models.

- Tungsten-coated. These are cheaper tools. But in terms of the quality of processing, they are not inferior to diamond models. Moreover, this type of cutters can be used to drill holes in stones: marble, granite, and so on. This tool also has its own design feature - it is a drill inside the cylinder, which functions as a centering element. It cuts into the ceramic and prevents the cutter from moving around the center. The diamond category also has such tools. Another advantage is that there is no need to cool the edges. Tungsten bites easily into hard surfaces even at high temperatures.

- Victory-coated serrated crowns. This is an even cheaper tool that quickly becomes dull. 20 holes and you can throw it away. Although for drilling several tiles, it will do just right. The maximum diameter of such cutters is 200 mm, so they can cut a hole even for a sewer pipe. True, you need to work very carefully with such a crown. Its teeth leave chinks at the edges of the cut, so after the process has been carried out, the edges will have to be worked on with a file or emery paper.

The choice of crowns should be the same as for drills. That is, in diameter, length and shank. The mode of use is also identical, the most important thing is to drill at low speeds. If the cutter design has a center-mounted pilot drill, then it can be installed in the drill and drilled with this tool. If there is no drill, then it is better to install the crown in a stationary machine.

Ballerinas

Another cutting tool with which you can drill large holes in the tile. In fact, this is a spear-shaped drill, on the rod of which a bracket is mounted. A cutter is attached to the latter. The rotation of the drill turns the cutter on the arm, which outlines the circle. The diameter of the cut can be varied by changing the distance from the drill to the torch by moving the latter along the length of the arm.

There are ballerinas with one cutter or two opposite each other. For this, a long bracket is installed on the drill with a place for installation and fastening in the middle. Thus, both cutters, set at the same distance from the drill, cut along the same circle. This increases the cutting speed and reduces the rejection of the process. Experts recommend choosing ballerinas not with a cylindrical rod, but with a hexagonal one.

Alternative option

There is another way how to drill a tile. This refers to a large diameter hole.

- A circle is drawn on the surface of the tile for the future hole. This can be done with a marker using a special template.

- Then, with a thin drill 2-3 mm in diameter, holes must be made right along the applied circle. The larger the number, the better the largest hole will be in terms of edge irregularities. If the cut made is covered with a decorative element, for example, when the mixer is installed, then the edges should not be modified. If the hole is completely visible, then the edges will need to be finalized. To do this, you can use a file or sandpaper.

Conclusion on the topic

Considering all of the above, it is necessary to understand that modern tools and methods of drilling holes in ceramic tiles make it possible to do this efficiently. Of course, there are certain requirements for the process itself. But their implementation is not difficult. The main thing, as mentioned above, is accuracy and caution. If you take into account all the recommendations, then it will be easy to drill the tiles, without scrap and cracking.