The bathroom is a room with high humidity, where, in the absence of good ventilation, condensation constantly accumulates. Moisture that remains on the tile leads to the formation of fungus, mold in the tile joints. In this case, high-quality waterproofing protection is a fundamental factor in a durable repair and a guarantee that in the event of an accidental leak, the rooms below will not be flooded. Therefore, everyone who plans to finish the bathroom thinks about the question of what is better to choose for waterproofing the bathroom under the tiles.

Wall and floor cladding in the bathroom is constantly tested for stability in everyday life. Temperature fluctuations, splashes, accidentally spilled water - all this negatively affects the appearance and performance of the coating. Moisture seeps through the joints under the tiles, accumulates under the tiles and in the places where communications are laid, creating favorable conditions for the reproduction of pathogenic microorganisms.

Waterproofing serves as a reliable protection of the walls and floor of the bathroom from excessive moisture and its consequences. In addition to the fact that a high-quality hydro-barrier ensures the durability of the finish and maintains its aesthetic appearance, it also reduces the risk of pipe leakage and flooding of neighbors from below.

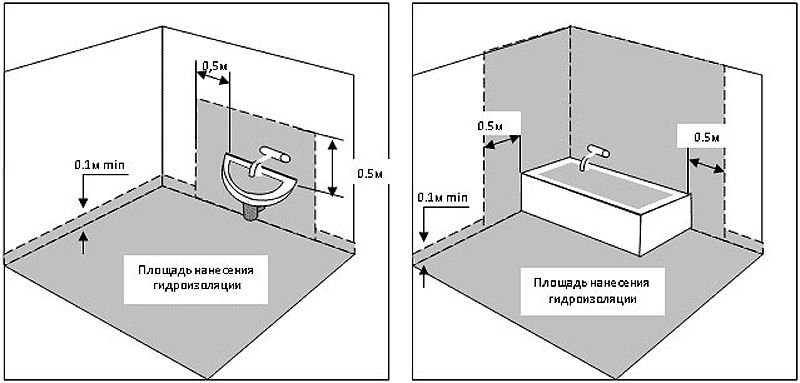

Laying waterproofing must be carried out around the entire perimeter of the floor, making an entry on the walls of at least 10-20 cm. Wall waterproofing is needed in those places where there is a suite, bathtub, washbasin, shower and other plumbing fixtures. At the same time, sections of the wall should be covered at least half a meter in each direction from furniture and plumbing. In addition, experts recommend waterproofing the plumbing cabinet to avoid water and sewer leaks.

Varieties of materials for waterproofing

The modern market offers various waterproofing materials, which differ in the method of application and composition. All materials for moisture protection of walls and floors in the bathroom can be conditionally divided into coating mixtures and rolls for gluing.

Coating materials are available in the form of a dry mixture and granules, with a pasty consistency or in a ready-made state. There are the following types of such compositions:

- Bitumen-polymer mass. It is delivered ready for use, it stretches and recovers well, it is resistant to thermal shocks and the influence of aggressive chemical components, it does not have strong odors and is safe to use. This material is used to insulate the floor in the bathroom before covering it with a thin screed.

- Liquid waterproofing (bitumen-latex). It is considered one of the most affordable ways to provide a bathroom hydro-barrier, it forms a monolithic moisture-proof layer without joints and connecting seams. On top of the liquid waterproofing, it is recommended to make a thin screed, and then lay the tiles.

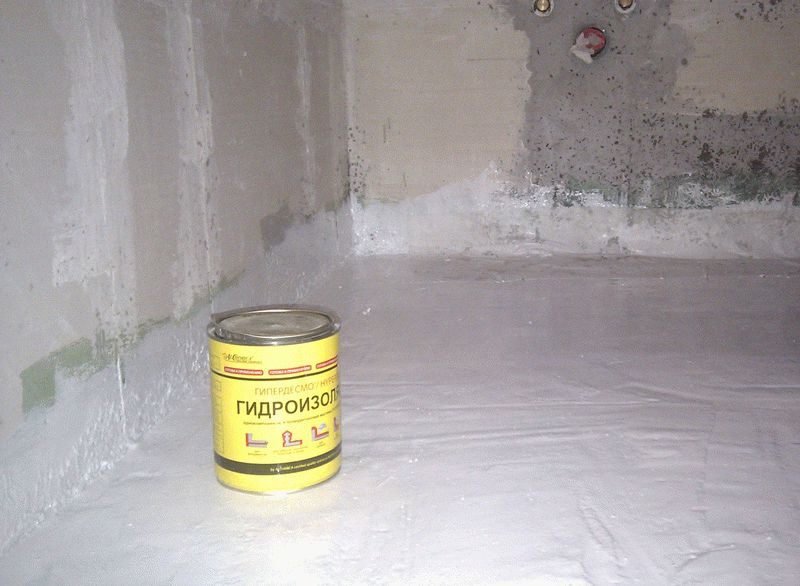

- Cement-polymer mixture. The composition quickly seizes and is ideal for waterproofing protection of walls and floors before facing. This material must be applied with a paint brush on a well-treated and primed substrate.

- Acrylic enamel. The cheapest and easiest option for bathroom waterproofing. Such a composition is short-lived and quickly begins to crack, so experts do not recommend using it.

Rolled waterproofing is made on the basis of fiberglass and polyester fabric, the bottom is covered with an adhesive composition for tight adhesion to the surface, and a special substance is applied to the upper part, which provides high adhesion with tile adhesive.

Before laying the material, it is necessary to clean and level the surface, while small differences up to 2 mm are allowed. As the advantages of rolled waterproofing, an affordable price and efficiency of repair work are distinguished, since the material does not require breaks for drying.

Features of coating and pasting waterproofing

Coating waterproofing of the floor and walls in the bathroom is carried out by applying a plastic material, the thickness of which can be from 1 mm to several centimeters. The main advantage of such protection is the formation of a seamless elastic coating, as well as the possibility of application to any surface. It is best to use coating compositions in cases where subsequent pouring of the screed is required.

On a note! One of the best options in terms of price-quality ratio is bituminous mastic. For a waterproofing layer 2 mm thick per 1 square meter, about 3.5 kg of material will be required.

For horizontal bases, it is recommended to use a bitumen and bitumen-polymer mixture with modifiers to increase strength. Diluted bitumen and mastic are poured onto the floor and spread evenly with a rubber spatula. On the surface of the walls, the composition is applied with a brush or roller in two layers.

Gluing waterproofing must be overlapped to obtain airtight seams. The main difficulty is to correctly calculate the amount of material and cut it. Flooring and leveling of canvases is also a very time-consuming process, in addition, after cutting, the material must lie down and straighten out within a day.

Arrangement of a hydrobarrier: when and how to perform?

Before starting repairs in the bathroom, many are wondering when it is necessary to carry out waterproofing - before or after the filler screed. Each of these solutions is acceptable and has its own advantages and disadvantages. It is recommended to fill the concrete floor with a screed after coating with a waterproofing material. This method will provide the most even surface, high adhesive characteristics of the base, and, accordingly, good adhesion to tile adhesive. For these purposes, it is better to use bitumen, bitumen-polymer and bitumen-latex composition, as well as waterproofing in rolls.

Some finishers equip a hydro-barrier on top of the screed, explaining that in the event of a leak, the concrete base will be reliably protected from moisture penetration. This technology has a place to be, but there is no guarantee that tiles glued to waterproofing with a thin layer of glue will last a long time and retain their aesthetic appearance. However, if you choose this method, then preference should be given to cement-polymer materials and rolled waterproofing.

Waterproofing over the screed is made with cement-polymer materials

Waterproofing over the screed is made with cement-polymer materials There is another option for arranging waterproofing - a combined method, which involves two layers of screed: under the waterproofing and on top of it. Such protection will cost many times more and take longer, but the result will be the most effective and reliable.

Wall and floor waterproofing technology

After preparing the base and dismantling the old screed, the following activities are performed:

- it is required to prime the cleaned base and leave to dry completely;

- with the help of beacons, pull out a screed with a thickness of more than 3 cm, into which the sickle mesh is recessed;

- after a few days, clean the base from dirt and prime with two layers;

- apply the selected coating mixture to the corner joints of the walls and floor, let it dry and stick a waterproof tape on these areas;

- apply waterproofing around the entire perimeter of the floor with an overlap on the walls of at least 20 cm;

- apply three layers in this way, while each layer should dry well;

- treat the last layer with concrete contact to enhance adhesion with glue;

- in a day, pour the floor with a second screed with a layer of about 1.5 cm;

- cover the base with a primer, let it dry and start fine finishing.

For waterproofing walls, it is best to use cement-polymer mixtures. Before distributing the moisture-proof composition, the walls must be covered with two layers of primer, paying attention to the corners and areas of the entry of communications and pipes. The corners should be glued with a special tape, and protective cuffs should be put on the pipes. Coat the walls with waterproofing with a brush or roller, and after they dry, cover with concrete contact. To ensure the high quality of the cladding, it is recommended to stick a reinforcing mesh on the moisture-proof mixture.