There is an attic in any country house. Very often this is an unused room, but in some cases some unnecessary things are stored here, or even some room is equipped. In any case, there must be access to it, and for this, stairs are made to the attic. They can be created from wood and metal - in this case, you can start making them yourself. Or they can be beautiful forged - such designs are usually created to order.

Primary requirements

Before you build an attic staircase, you need to think through several of its features. First, it must be comfortable and safe to use. Moreover, these two indicators depend on the constructive principle of the staircase and attic itself. An important role is played by taking into account the type of stairs, the width of its steps, and the height of the rise. The height of the stairs is calculated depending on what its design will be. If it is a folding type, then you need to carefully consider its size when folded.

The steps must be of such a size that it is convenient and safe for anyone to climb. The correctness of the design also depends on the location of the steps: the distance between them should not be too small or large. Failure to comply with these requirements will violate safety regulations.

The width of the flight of the stairs to the attic should be at least 0.8 m. It is important that the angle of inclination is observed: this must be thought out even at the design stage of the structure.

Ladder types: folding or stationary?

The choice between these two types of structures depends on how large the attic area is. Of course, a stationary ladder is more reliable and safe, but it is also solid, that is, a lot of space is required for it. That is why many people prefer folding attic stairs: they are convenient, take up little space, due to the fact that they can be folded. Most often, such structures consist of several sections that are superimposed on each other, thereby saving space. Moreover, they can always be adjusted depending on the required size.

Or retractable?

These designs are becoming more and more popular due to their advantages:

- are cheap;

- easy to assemble;

- take up little space due to the accordion-shaped design;

- reliable;

- mask the structure with an attic hatch.

All these advantages make retractable ladders so much in demand. How to make it yourself?

Self-assembly of a retractable ladder: the main steps

The very first step should be a thorough analysis and verification of the dimensions of the hatch opening. This is necessary in order for the parameters you have chosen to match the dimensions of the stairs. Then the location of the bars is thought out - first at the bottom, then at the top. Special spacers are located between the opening and the staircase - they will help to better fix the structure. Once it is in place, the spacers can be removed.

Or outdoor?

If space does not allow the installation of retractable ladders, you can replace them with an external structure. It will provide a connection between the outside world and the inside of your home. The main thing is to remember the safety rules, since the operation of such a structure has its own characteristics. When installing an outdoor staircase, it is important to choose the right material: it must be resistant to sunlight, have increased abrasive wear, reliable and durable.

Ladder made of wood

Wooden stairs to the attic are the easiest option, which you can create with your own hands. This can be done in several ways. Let's consider the simplest and most feasible ones.

Method 1

To make an attic staircase, first you need to take measurements: we need the parameters of the height of the room, the estimated angle of inclination, which most often reaches 30 degrees, while the height is about 2.5 m.In order for the staircase to be reliable and correct in terms of design, you need to think over and draw up drawings correctly. The simplest wooden stairs are created on the basis of bars for kosour, bars corresponding to the width of the stairs, for fastening, overhead hinges and boards, from which we will make steps. Yes, and do not forget about the folding hangers - the hatch cover will be fixed on them. The installation process itself is as follows:

- Steps are installed and securely fastened between the stringers. This is done either by fastening according to the "thorn-groove" type, or on self-tapping screws, or on glue. It is better to treat the steps with anti-slip pads - they will increase the safety of the structure.

- The ladder is first fastened under the ceiling opening on two bars, which are equal to the width of the ladder. They are connected with loops.

- We check how efficient the hinges are, after which we finally tighten the fasteners.

This is the easiest way to create an attic staircase.

Method two

This is a more time-consuming method of making a staircase, which can be easily mounted even in a country house. It looks more aesthetically pleasing and has a more reliable design, which is important in conditions of heavy load on it. The structure itself will be movable on one side, and the other half will be attached to the wall. To create such a staircase to the attic, we need:

- two boards with a length corresponding to the height of the ceiling and the angle of inclination;

- boards for creating steps at least 0.5 m wide and about 3 cm thick;

- bolts, screws as fasteners;

- card loops with which the steps will be attached.

It is important to arm yourself with a drawing - it will allow you to perform all the work with high quality and accuracy. After determining the angle of inclination, you need to saw off the bars from above and below so that they firmly rest against the floor. The boards along the entire length are divided into equal segments - here the steps will be located at the distance that you need. The fastening of the steps is done with card loops, and after the completion of the structure, you can make it exquisite by treating it with varnish or painting it.

Metal stairs

Attic stairs made of aluminum look very beautiful, especially if your country house is decorated in the style of "minimalism" or "high-tech". What is metal good for? First, it is more reliable. Secondly, such structures are treated with special compounds that protect the surface from mechanical stress or corrosion. Thirdly, metal structures are able to withstand heavy loads.

The most popular among buyers are sliding-type metal stairs, which take up little space. They are relevant for rooms that are small, that is, where rational use of space is required.

How to do it yourself?

Despite the complexity of the technological process, you can make a metal staircase yourself. Moreover, it can be made both from metal and from a combination of materials. To make the simplest metal staircase, we need to prepare:

- welding machine;

- mechanical saw;

- an emery wheel, with which we will remove burrs on the metal;

- a circular saw and a clamp for joining parts, if the ladder will have wooden parts;

- pipes;

- steel sheets.

Note that the amount of materials is calculated based on the drawing. With a welding machine, we will make strong seams, so the staircase will be a monolithic and durable structure.

Such an aluminum or steel staircase will be built on the basis of a channel (size 8-10). The steps are made of sheet steel, if they are without additional finishing, you will need a grating on the step, which will protect against falling. The railings are made of angle steel, and the tread supports are made of reinforcement. First, the supporting devices are installed and welded onto the beam, then the brackets for fastening are welded.

Metal attic stairs may have wooden treads, but first you need to think about where the additional fasteners will be located. On metal steps, holes for self-tapping screws should be located at a distance of 15 cm from each other. A plywood backing is mounted to the metal treads - it is attached to mounting glue, which, after hardening, retains its shape.

Aluminum finished staircase

Very often, many people prefer to buy ready-made structures, rather than mount them on their own. But in this case, you will have to work hard, since they are delivered disassembled. How to assemble? The general scheme of work is approximately as follows:

- First, a sketch of the future staircase is created.

- 4 identical segments are cut from a metal profile or pipe.

- The pipe is fastened in a vice and thoroughly cleaned from rust.

- Steps are cut from a metal sheet - they must be of the same length.

- Treads are tried on on a flat surface and adjusted to size.

- The steps are attached to the supports by welding - this is a more reliable option than corners and bolts.

- At the bottom, the staircase is finished with rubber heels.

Forged structures: beautiful and modern

Very often, in country houses, wrought-iron stairs connect the premises with the attic or attic. Moreover, they can be simple screw, or they can have ornate patterns, which allows them to fit into any room in terms of stylistic orientation. All spiral staircases can be divided into several types:

- in the first version, the staircase is carried out with support on the central pillar and walls;

- in the second, the spiral staircase is removed from the walls and is attached to the support pillar with steps;

- in the third case, the staircase with a turn does not have a central pillar, but rests on spirally curved bowstrings;

- the fourth option is a reliable metal ladder, which rests on a monolith pillar based on a steel pipe.

The most convenient are the stairs, the span of which is up to 900 mm with the diameter of the entire staircase up to 2200 mm.

And if you buy?

If you do not want to do your own installation, you can always buy the same wrought-iron stairs, which are quite difficult to assemble on your own, and even more so to invent and make. A large selection of attic stairs is offered by many brands, not only in Russia, but also in other countries of the world. Let's consider the most popular ones:

- STANDART ISO PLUS (MINKA, Austria). This folding wooden ladder is made of quality MDF and is designed for a maximum load of 150 kg. There are special protective caps for the legs, and with the help of a metal handrail, maximum safety is ensured. This is a compact staircase, the price of which is 8,200 rubles on average.

- The Danish company VELTA offers economy class constructions that can be installed in the attic or in the attic. For 6,000 rubles, you get a simple staircase that is compact: it consists of three sections that can be conveniently assembled and retracted into the ceiling.

- FAKRO ladders are made from winter pine, therefore they are reliable and durable in operation. This company offers a wide range of products that are compact and in a wide price range. The insulated manhole cover is the main advantage that this staircase has. The price of the models starts at 8,000 rubles. It is also important that all the connections of the structure are reliable and durable, the steps are supplemented with anti-slip recesses, making the operation safe and comfortable.

conclusions

Now you know how you can make a staircase to the attic with your own hands. With the simplest materials at hand, you will create a concise yet comfortable wood or aluminum structure.

Having started the construction of their own cottage, not everyone understands that such a trifle as a hatch to the attic with a staircase is an obligatory element for the device in any house. A small door will make life in the house safer, even if the attic is not in use. In addition, it is important to make the approach to the attic hatch as comfortable and safe as possible.

The space under the roof of a residential building can be used for different purposes. Even if the attic is not residential, it functions as a technical room. But more often the owners of cottages still use the space under the roof with benefit, placing living rooms or space for relaxation there.

Regardless of the purpose for which the attic or attic is used, this space must meet certain safety requirements:

- It is imperative to have a free passage to the space under the roof to extinguish a fire. Most often, a hatch is arranged for this. The materials from which the door is made must comply with fire safety standards and have a fire resistance of at least EI30.

- Materials for the construction of the roof and attic finishes are compulsorily treated with fire retardants.

- Large attic spaces are divided into compartments that can block the spread of the flame.

- It is prohibited to arrange storage facilities under the roof.

If an attic is being built, then it must have escape routes separate from the living quarters. Despite the seriousness of the requirements, it is not difficult to implement them in private construction. Usually for this it is enough to arrange a hatch with a ladder in the attic ceiling.

Old and new

If you look closely at the houses built in the last century, you will notice that they are all equipped with external attic doors. People have always understood that the entrance to the attic is necessary to make the house more secure.

Modern construction technologies and materials allow you to arrange a comfortable and beautiful entrance to the attic from home. At the same time, the installation of this structure should be approached with the utmost seriousness and pedantry. Despite the seeming insignificance, the reliability of this door may well one day save the structure or life.

On a note! Negligence in the device of the attic door, at least, will lead to drafts.

If you add the absence of a vapor barrier layer to the wrong design, then as a result you will get high humidity under the roof and, as a result, the multiplication of mold and mildew on the floor materials.

Manhole size

There are no regulatory restrictions on the size of the hatch. Here you should be guided by economy, comfort and common sense. First of all, the door to the attic should provide easy access to the space under the roof. Experimentally, some optimal criteria have been identified:

- the width of the door depends on the dimensions of the staircase and usually exceeds the dimensions of the steps by 10-15 cm;

- if the staircase is mounted with a railing, then the opening must exceed the width of the march by 20 cm, least;

- the length of the doorway is usually done 1.2m, this size allows you to move freely up the stairs;

- the height of the slabs at the installation site of the hatch must be at least 2m, it is important to take into account the size of the disassembled ladder;

- the most convenient opening will be internal: the doors open towards themselves in the direction of the living space.

Important! There should be a mechanism for fixing the leaves in the open and closed position.

Types of hatches

The door to the attic can be implemented in various ways. The choice of the opening mechanism and the type of hatch device depends on the version of the stairs, as well as on the frequency of the required passage to the attic. The most common implementation options:

- Inspection hatch settles in a situation where the attic is not used as a living space. Ideal for roofs with an acute slope. Usually operated in conjunction with a ladder.

- Attic entrance a very beautiful solution and, as a rule, is combined with a door to the roof. This method is not recommended for an independent device, since it requires certain construction skills. In addition, it is necessary to correctly calculate the possible loads on such a door.

- Vertical sunroof is built in buildings with different levels of premises. In fact, this is a lowered door from the living room to the space under the roof. An uncomplicated method, but it is used extremely rarely, since it is created in buildings with a specific layout.

- Horizontal entrance to the attic- the most common way for private construction. It is quite possible to device on your own.

We will consider the device of horizontal hatches in more detail.

Prices for roof windows

Mansard window

Requirements for attic stairs

Carrying out an independent design and construction of an attic staircase, you should know what requirements are imposed on such structures. Limitations on the angle of inclination and width of the tread were identified empirically and confirmed by the calculations of engineers. These criteria are spelled out in SNiPah and in the case of mass development are mandatory. This was done in order to make the operation process as safe as possible under conditions of rare use.

Before designing a staircase to the attic or attic, you should familiarize yourself with the basic safety criteria:

- the length of the disassembled ladder should not exceed 3m;

- span width must be within 0.6-0.7 m;

- the height of the step is chosen based on the height of the residents, but usually fluctuates in the area 0.2m;

- the number of steps, that is, steps to climb, must be odd and no more 19;

- optimal angle of inclination of the attic staircase 60-70 0 ;

- tread width 24 -30 cm.

On a note! The tread material must be strong against fracture and at the same time have some bending play. Comfortable tread thickness of the step material 18 - 20 mm.

Types of structures

Depending on what kind of room will be under the roof and how much the area of the building allows, home owners can arrange a different passage to the attic.

All types of stairs can be divided into 3 methods of construction and operation:

- Stationary.

These are marching, screw, cantilever structures. That is, the staircase, which is being built together with the building, is connected with it by one reinforcement system, distributing the load on the load-bearing parts of the building. These stairs have the following characteristics:

- thoroughness;

- significant weight;

- long service life;

- high strength.

In addition, such a structure always takes up the usable area of the lower floor. Even with the device of helical steps, the most economical in terms of volume, you will have to sacrifice square meters.

On a note! It is worth giving preference to a stationary staircase if the attic space is residential and its daily use is planned.

- Portable (attached).

The use of portable ladders to visit the attic is quite common in cases where the roof space is technical and does not require frequent visits. Moreover, this is the most budgetary method of the device and the most inconvenient and traumatic. It is not recommended to use the ladder alone without belay from below. In addition, the stepladder or ladder must be stored somewhere and, if necessary, brought to the area of the attic hatch.

- Foldable.

If the attic has a functional value and is used often, but not daily, folding ladders are the best way to arrange a passage. These structures are retracted into a hatch or wall and for this reason have obvious advantages:

- do not take up space on the ground floor area;

- when unfolded, they are a strong and stable structure;

- do not require the organization of storage space.

Folding ladders, as a rule, do not have a riser, so the width of the tread is often reduced, rightly assuming that a 2/3 foot stop is sufficient. But when designing, it should be borne in mind that too narrow a tread will make the staircase an object of increased risk, therefore the steps should still be near 20 cm wide.

Types of folding ladders

A folding ladder, even complete with an attic hatch, can be purchased ready-made, or you can assemble it yourself. Let's describe the possible most common types of mobile steps:

- Telescopic. The guides for the steps are laid out according to the matryoshka system, that is, one to one. The steps are installed on the guides using locking mechanisms. Not the most reliable type of ladder, problems, as a rule, arise precisely with clamps.

- Scissor. Another name for such steps is an accordion. It is on the principle of bellows that the staircase is stretched with a simple downward movement. When assembled, it is quite compact. This design can be purchased as an automatic extension.

- Sectional folding. The ladder segments are folded, as in the scissor version, but in rather large sections, and not incrementally. For this reason, the assembled staircase is rather cumbersome, but at the same time it does not take up space on the lower floor, since it is retracted into the hatch. The absolute advantage of this design is the price, it is the most economical option.

- Folding. Ladders that are fixed to the nearest wall and retracted into it when assembled. In working order, such a structure is very similar to a conventional marching structure. The advantage of such a march is the normal angle of inclination, usually 45 0 ... But for use, you will need a free area of the lower floor. In addition, the assembled staircase on the wall will not decorate the interior.

Find out with your own hands, as well as see the drawings and videos, in a special article on our portal.

Prices for various types of folding loft ladders

Folding attic stairs

Diy wooden attic three-section staircase

The first thing to do is to cut an opening in the ceiling at the chosen location. All further calculations will depend on the dimensions of this opening. Please note that the hatch will be attached to the body of the ceiling, therefore, if necessary, it should be strengthened.

After the opening is ready, they begin to draw up a project for an attic hatch with a staircase. The drawing should indicate the following dimensions:

- ceiling thickness;

- the length and width of the hatch;

- angle of inclination of the stairs;

- the width of the flight of stairs;

- length and number of sections;

- the number of steps and the distance between them;

- the width of the tread.

The most difficult from the point of view of calculations is the moment of determining the length of the stairs in disassembled form. For such a calculation, you will need to remember school mathematics and find Bradis tables, you will need the value of the sine of the angle:

- determine the location of the stairs on the drawing;

- measure the angle of inclination (remembering that it should not be steeper than 70 0);

- we calculate the length of the stairs using the formula L = H / sin, where L is the length of the stairs, H is the height from the floor to the attic hatch, sin is the sine of the tilt angle.

On a note! A simpler, but less accurate way of calculating is to determine the size of the hypotenuse, in a triangle, where the legs are the height to the hatch and the estimated length from the edge of the hatch to the place where the stairs are fixed on the floor of the lower floor.

Section sizes are calculated as follows:

- the first is the longest, the size of the hatch is reduced by 10% ;

- the second is less than the first by 10%;

- the third is the remaining length to set the entire size of the march.

The project has been calculated, the materials have been purchased in the required quantity, you can start producing a hatch with a folding ladder.

On a note! Once the project is ready, count all fasteners, including connecting hinges, hinges, locks, and an external handle for easy opening of the hatch.

Timber prices

Manhole door manufacturing technology - step by step instructions

Any door consists of a box (frame) and a door (leaf). The box is fixed in the opening, and the canvas is fixed to the frame.

The size of the box should be slightly smaller than the size of the opening for the hatch. Each side should have 2 - 3 cm on the formation of the assembly seam.

The manufacturing process is as follows step by step:

Step 1. The frame is knocked out of a bar or board. Corner connections are made according to 45 0 ... All parts are fastened with glue or self-tapping screws. For greater strength, the corners of the box can be fixed with furniture corners.

Step 2. The frame for a dense one is also assembled from a bar. The structure can be reinforced with a crossbar.

Step 3. From the side of the attic, wind protection material (waterproofing) is laid into the canvas. Insulation is placed inside the canvas, for example, mineral wool. The inner side of the door is laid with a vapor barrier membrane.

Step 4. On both outer sides, the door is sewn up with plywood, at least 8 mm thick.

The canvas should fit snugly but freely in the frame. Before starting work, all wood should be treated with a fire retardant compound.

On a note! The hatch box is mounted flush with the lower plane of the ceiling, this should be taken into account when choosing the size of the timber for the frame.

Construction boards prices

Construction boards

Assembling the stairs

First of all, it is necessary to cut the beam into the string of the staircase. The result should be three pairs of bars of different lengths. It is better to cut out the lowest pair with a small margin, so that, upon installation, cut the corner at the end of the bar for firm fixation on the floor.

The algorithm of actions is as follows:

- saw the boards for treads in the required amount;

- on the bars of the bowstring, make markings for attaching the steps;

- fasten the beams in pairs with tape and drill holes in the places where the steps are attached;

- drill the places for installing the hinge mechanism at the ends of the bar to connect the sections to each other;

- assemble the entire structure with self-tapping screws.

Video - Self-assembly of the attic staircase on metal fasteners

When marking out the fastenings of the treads to the bowstring, it is better to focus on one edge and make one hole only. After the ladder is installed at the desired angle, one step is set and a second hole is made so that the tread is strictly horizontal. To repeat the required angle, make a template from cardboard and drill the attachment points for the remaining treads. Attach the ladder to the door after fitting.

Installation process

If the work is carried out by two or more people, you can assemble the hatch together with the ladder to the attic as an assembly. The design is quite heavy, so it is almost impossible to carry out such an operation alone.

If everything is assembled and measured correctly, the installation process will not be difficult:

- A box is mounted in the thickness of the overlap. Everything is fixed on the anchor screws. The frame is fixed in several places: at a distance 10-15 cm from the top of each corner and with a step 40-50 cm along the length of each side.

- The door is hinged to the frame. A hinge for attaching the stairs and all locking mechanisms are installed on it in advance.

- The upper section of the ladder is mounted to the fixed door.

- The entire structure of the march is assembled using hinge mechanisms.

The assembly seam is foamed. After that, the inner side of the seam should be glued with metallized tape, and the upper part should be laid with PSUL waterproofing tape. After such insulation, the seam can be closed with a cover strip or any other decorative material.

Important! The seam on the side of the PSUL tape does not require additional protection. Plastering according to PSUL is categorically impossible.

Video - The technology of installing an attic staircase into a finished ceiling

Conclusion

A staircase with a hatch to the attic is a must-have element in any building. The types of stairs and hatches, as well as the methods of their installation, must comply with fire safety requirements. At the same time, you can assemble all the structures with your own hands or purchase a finished product and order installation at a specialized company. The modern construction market offers a large selection of ready-made structures, as well as various materials for self-production.

The attic is a traditional space in almost every country house. Its functionality is unusually wide. For example, this room is used as a storage room or workshop, some homeowners even design the attic as a living room or bedroom. In fact, the functional purpose of such a room depends solely on your own imagination, as well as financial capabilities. However, despite the wide variety of design options for the attic space, it is worth knowing that the attic staircase with a hatch is an integral part of it. If you do not build this structure, then you simply cannot get into this room. Creating an attic staircase is a fairly simple matter, in connection with which you do not even have to contact the professionals in the construction industry.

Classification of structures

Actually, the most time-consuming process in organizing the attic space is the construction of the stair segment. Before creating a project for a specific staircase for your home, you must first determine the category of construction. There are such options:

- folding;

- stationary;

- portable.

Features of various designs

Experts in the construction industry call the wide marching structure the most reliable in the relevant segment. It should be noted that its durability, reliability and safety cannot be compared with constructive analogs on the market. Meanwhile, despite the large number of advantages of this option, the choice in its favor is sometimes impossible due to the banal lack of the necessary free space. Thus, if you do not have a large area for the stairs, then the stationary model will not suit you. However, do not despair, because you can always build a folding ladder. Its design has the best characteristics from stationary and portable counterparts. For example, it is not as reliable and safe as a stationary marching model, however, to organize such a structure, it is necessary to have a very small amount of free space. In addition, it is the folding models that are easiest to implement without the help of experienced professionals.

Temporary solution

Portable models will be allocated in a separate category, however, it is quite extensive. The variety of portable products is incredible. Meanwhile, do not forget that the daily use of such a product can never become safe or comfortable enough, and the ladder itself is not able to compete with stationary and folding models in terms of operational and technical characteristics.

Selection of building materials

In the process of creating an attic staircase with your own hands, namely, its preliminary drawing, you should pay attention to what building materials are usually used in this case. Despite all the variety of products in the segment of building materials, any experienced builder will tell you that there are certain types of goods that show themselves in the best way during operation. As a rule, all the main parts of the structure are made mainly of wood, while fasteners and fixing elements are made of metals. Thanks to the competent selection of materials, the attic staircase with your own hands, the drawing of which was made by a non-professional, will be an order of magnitude stronger and more reliable.

How to make your choice?

Due to the fact that building materials for folding stairs to the attic are presented in a variety of price segments, source materials and characteristics, it is quite easy to drown in the sea of information about them. To minimize the time spent on searching and choosing the best options, you should be guided by a number of rules:

- Specify the type of functional purpose of the structure, as well as its main parameters, including design features, sectionality, width, etc.

- Choose building materials in strict accordance with how actively the product will be used and in what conditions.

- Determine the negative factors that can reduce the operational rock of the product.

The main thing is to correctly define the function

Any specialist with the required level of qualifications and experience in working with these types of objects will tell you that the final result of construction work on erecting stairs to the attic with your own hands largely depends on the competent determination of the functional purpose of the product. This parameter allows you to calculate the indicator of the permissible load for each step of the product. The standard value of this indicator for a metal product reads about 250 kgf, but wooden models are designed only for 150 kgf. In addition, it should be borne in mind that the above indicators are valid for products made by professionals, while homemade objects have slightly lower parameters. In general, the indicator of permissible pressure on a step does not mean that it will not bear more stress. However, if you overload the structure too often, then it will become unusable in a fairly short time.

So, the main criteria by which the choice of the optimal option is carried out are as follows:

- free space in the room;

- functional purpose of the object;

- the required angle of inclination of the product.

Stages of work and their features

Actually, experts say that there is nothing particularly difficult in creating a ladder with a hatch with your own hands. It is enough to adhere to certain rules, proven over the years. For example, when drawing up design drawings, it is worth being guided by the regulatory and technical documentation, which, in addition to general conditions, also contains specific parameters of standard products. In addition, on the Internet, a lot of ready-made schemes for every taste are offered in the public domain. You can take a ready-made version and start bringing the project to life, or you can slightly modify it in accordance with the individual characteristics of the house.

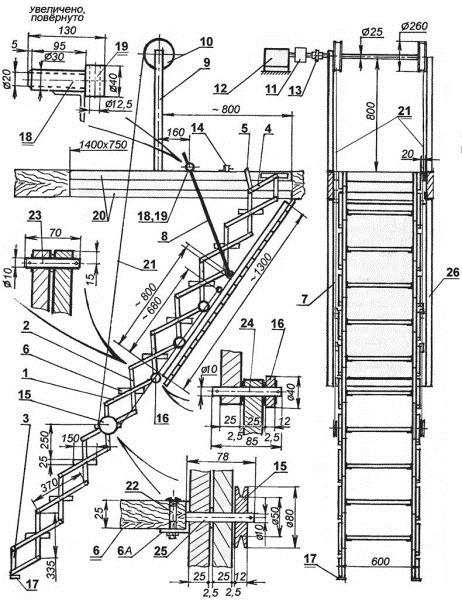

Figure 9.

What to consider when designing?

The most general requirements of regulatory and technical documentation can be reduced to a number of simple and understandable conditions:

- the ergonomic range of product width is from 60 to 100 centimeters;

- the best height is three and a half meters;

- the maximum number of steps - 15 pieces;

- the distance between adjacent steps should be about 20 centimeters;

- the step height comfortable for a person reaches about 20 centimeters, a deviation of 2 centimeters is allowed;

- if we are talking about a folding structure, then when creating a project, a permissible load of 15 kilograms is taken.

Tools

Having decided on the independent implementation of construction work, it is very important to stock up on a certain set of inventory, so that during the implementation of the product project, you do not stop due to the banal lack of a screwdriver or tape measure. So, the standard set of tools consists of the following items:

- polyurethane foam;

- bars;

- self-tapping screws;

- electric screwdriver;

- hacksaw;

- yardstick;

- anchors;

- screwdrivers.

Staircase construction is not difficult

Staircase construction is not difficult Location features

All the nuances of the location of the object in the room will become visible during the construction process. This is especially true if you are engaged in the creation and subsequent implementation of the project yourself. Remember that the product in no way can reduce the comfort of the room. That is why ladders with a hatch are not located in bedrooms, living rooms and kitchens. However, if necessary, you can diversify your staircase project with an interesting design. Thanks to this, the product will be able to harmoniously fit into the overall interior of the room.

Project implementation technology

By following a certain technology, you can quickly and efficiently implement even a complex project. So, if you chose metal as the main material, then remember that the following stages are carried out:

- the drawing is applied to sheets of cardboard;

- the cardboard elements of the future product are cut out;

- hinge markings are applied on metal strips and special holes are prepared;

- prepared parts are fixed to each other;

- the required angle is measured and the structure is expanded in accordance with the obtained parameters;

- on metal sheets, markings are applied to those places that will subsequently be covered by corners;

- elements are cut out using a special tool;

- an aesthetic appearance of the object is given;

- existing corners are rounded;

- the workpieces are fastened in pairs.

As you can see, the technology of work on the implementation of the staircase project with your own hand is quite simple. It applies not only to metal objects, but also to wooden products.

In order for the appearance of the attic staircase to be as attractive as possible, do not be too lazy to carry out preparatory work on the surface of the building material. This is, for example, the application of a special primer before coating the surface with a coloring agent.

Do not be afraid of difficulties, because the technology for the construction of a staircase only at first glance may seem problematic to you and requires experience in the construction industry. Applying the optimal amount of effort will help you achieve maximum results.

In private houses built with pitched roofs, there must be attic spaces. They can be assigned a technical role, but more often they equip living rooms-attic. Everyone needs usable space, but how to get to the attic if its operation was not planned when creating a house project? You can make a stationary ladder, but this task is very troublesome.

Now on sale there are attic stairs with and without a hatch, which are easily installed in the ceiling between floors. The structures take up the minimum amount of free space, are functional and practical. Thanks to these staircase systems, you can comfortably get to the attic floor.

Choosing the type of stairs

Attic lifting structures can be installed outside or inside the house. If the attic is residential, then use the second option. But even if the premises are not residential, access to it should be as safe, convenient and inconspicuous as possible.

The following types of stairs are used to access the attic:

- monolithic marching or screw structures;

- portable in the form of stepladders or ladders;

- built-in solutions.

The choice of one or another staircase structure depends on the operating conditions, strength requirements, and the volume of space in the floor. If a folding structure is purchased, then the dimensions of the product, the material of manufacture are taken into account.

For residential premises, it is better to purchase wooden solutions. In a house with a modern interior, metal stairs are more suitable.

It is important to pay attention to the distance from the floor to the ceiling. If the ladder model has a higher height than necessary, then the possibilities for its adjustment should be clarified - the ladder should not just hang on the ceiling, for safe use it should be resting against the floor surface.

The size of the opening is also important. Very often it is limited by the distance between the floor elements or the overall dimensions of the hatch in a reinforced concrete structure. In this case, if there are no restrictions, you can purchase a model for the largest opening possible. If a construction with a hatch is chosen, then the latter must be qualitatively insulated.

Stationary

Stationary monolithic stairs to the attic are marching or spiral structures. This is one of the most traditional types of stairs in private housing. Such solutions are solid, aesthetic, convenient and safe. But these are massive and expensive products that take up a lot of free space.

Among the advantages of such solutions, one can note the presence of handrails, as well as protective fences. This is very important if elderly people or small children live in the house.

Portable

These attic stairs are nothing more than stepladders and ladders. They do not take up much space, are inexpensive, and after use they can be removed to the pantry. It is very simple to use them, but you need to understand that using a stepladder is not always convenient and safe. A ladder is used only during construction or renovation, as well as in summer cottages.

On sale are steel, aluminum portable and ladders of domestic, European and Chinese production. Products differ in price, quality, number of steps, as well as the presence of additional elements.

Foldable

The folding ladder combines the advantages of the first and second options, but it is also not without its disadvantages. Such models are safe, easily and easily fit into any interior, save space, and are easy to use. The democratic price of models with a hatch will delight, and may even surprise.

The folding ladder can be made of aluminum alloy and wood. Manufacturers often combine these materials. From wood, mainly durable species are used. So, the attic folding system "Fakro" is made from high-quality coniferous timber. Other brands use beech, maple, oak.

A foldable aluminum ladder is suitable when it will be used constantly. This ladder system is characterized by increased wear resistance and greater strength.

Sliding

A sliding or retractable ladder is a metal or wooden structure. It can consist of two or more sections. On the upper section there are guides along which the lower part rises and falls. The feature of the sliding / sliding model is in the complete absence of spring elements - this allows you to reduce the price.

The sliding system is capable of withstanding a load of up to 200 kg. The wooden pull-out model can hold up to 150 kg. The mass of metal products and models made of wood is relatively small, the dimensions are compact, the march has an insignificant scope. Since the device is simple, the mechanism is durable.

These models are mainly used in a private house with low ceilings. In most cases, the structure is built into the hatch and insulated.

Folding with spring mechanism

A folding ladder with a spring mechanism is the most common type. The principle of its operation is simple. Two mechanical assemblies for opening and closing the hatch are responsible for the quality and reliability of work. The sections of the folding ladder are connected by powerful hinges with a shoe or lever hinges.

The ladder can be purchased ready-made or made with your own hands from an attached one, it is only important to calculate the required length of the sections. The folding ladder mechanism is designed to provide smooth operation when the lid moves down and zero gravity when it closes back. A special return spring is installed along the box.

Related article: Telescopic aluminum ladder - a mobile ladder for all occasions

Scissor ladders are also presented. Here the steps are interconnected with special scissor brackets. When lifting, the structure is folded in such a way that each step fits very tightly to each other. When lowering the ladder, the brackets open and the steps are held at a convenient distance for ascent / descent.

Most often, manufacturers offer metal products. Additionally, the models are equipped with comfortable handrails.

Other important advantages include high fire safety as well as durability. The model is capable of withstanding up to 200 kg of weight. These solutions are more compact - the ladder folds out in a straight line, and no additional space is needed directly next to the hatch.

Telescopic

The telescopic system is not very popular in the domestic market, but in Europe such ladders are in great demand. The main material is aluminum. The ladder is assembled from separate hollow tubes, when folded, the steps can fit very tightly to one another, and when unfolded they are securely fixed.

The sides are formed by hollow tubes ranging from larger to smaller diameter. During the folding process, the side elements fold into each other.

The downside is that the telescopic structure has a load limitation - it is not designed for a large weight, and also that the system is not equipped with handrails for easy lifting up. The staircase is also not particularly stable.

The folded telescopic ladder has a compact size - this model can easily be built into ceilings. There are also structures made of wood, but such products are not particularly durable, therefore they are used less often.

Simplified folding ladders

These structures are not hidden behind an attic hatch, but they can be easily hidden in a corner or behind some kind of interior decoration. This is a rare type of attic stairs. They consist of two or more sections, connected by hinges, and fold according to the principle of a book - part of the ladder leans back and compactly leans against the wall.

In the video: an overview of attic stairs and tips for choosing.

Material selection

In the manufacture of attic stairs, manufacturers use a variety of materials. These are mainly aluminum and its alloys, natural wood, and steel. The choice of this or that material depends on the type of staircase structure, as well as on the purpose - whether the product is intended for indoor or outdoor use.

Wooden

A wooden ladder is the most common and affordable option. If the attic in a private house is not used so often, then you can purchase the most inexpensive products - ladders. If the entrance is beautifully decorated or the staircase is needed for the street, then other requirements are put forward - the wood should not rot, dry out after several years of use.

The types of wood are used very different, you should choose them based on the tasks. So, in classic interiors you can buy products from oak, ash and other species. Stationary stairs with railings are most often made from more expensive species, but folding ones are made from pine.

Metal

A metal product is a guarantee that the lifting system will work for many years without wear. This is especially true for models made of aluminum or stainless steel. Steel, if the product is to be used outdoors, will require anti-corrosion treatment.

Metal is more attractive in modern interiors such as hi-tech and minimalism. Telescopic and pull-out systems fit in especially harmoniously.

When choosing the dimensions of the stairs, you should be guided by the already proven, as well as approved standards:

- The recommended march width for comfortable ascent / descent is from 650 to 1100 mm.

- Height - no more than 350 cm. If you choose larger sizes, the product will lose its rigidity and safety.

- The number of steps - no more than 15 pcs. Sometimes this figure can be increased, but the stairs will have to be additionally strengthened.

- The distance between the steps is about 15-20 cm, the thickness of each step is 2 cm, but this is not rigid.

- The angle of inclination of the stairs is 60-80 degrees. Positioning the ladder at small angles requires free space, and a large angle reduces safety.

Dimensions of stairs with a hatch

To have a complete picture of the overall dimensions of typical lifting ladder systems with hatches, you can consider the parameters using the example of one of the largest manufacturing companies.

60x60

This category includes stairs to the attic with a hatch, the dimensions of which are 60 by 60 cm. Such models are available in the catalogs of many manufacturers, but the size is non-standard. The stairs themselves are compact and do not take up much space; they can be installed in any room.

60x80

A ladder with a 60 x 80 cm hatch is a more standard solution. Such models are available from various manufacturers in large quantities. These products are popular with customers.

Luke

The hatch is not the easiest part, and yet an important part in a folding or folding ladder system. There are several types of hatches:

- horizontal - typical solutions installed in ceilings;

- vertical hatches;

- attic structures;

- inspection hatch for checking the condition of the attic.

The first, horizontal option is the classic and the most commonly used design. The manufacture of such a hatch and the installation of a ladder to it can be done by hand, there are drawings and everything you need on the Internet. However, there are models of stairs on sale that are already equipped with a hatch.

The mansard hatch is multifunctional. This is a hatch for access to the attic, and at the same time an exit to the roof. It is complex, but very functional. The downside is that you won't be able to make such a hatch on your own - you need to order the product in the studio, the installation should be carried out by the hands of experienced professionals.

With ladder

Hatches are equipped with folding, sliding and scissor ladders. Such solutions are most often installed in rooms with a lack of free space. Among the pluses is compactness. You can choose a staircase without focusing on the interior and style of the room - the staircase itself is hidden inside the ceiling.

Some hatches are equipped with a special mechanism - lifting devices will lower the ladder down in a few seconds. If the built-in ladder is of a manual type, then one slight movement of the hand is enough to lower it.

The only drawback of the design is the difficulty in carrying out the installation work on your own. However, if you strictly follow the manufacturer's instructions, then everything will work out.

No stairs

Everything is much simpler here, it is a wooden or plastic hatch. There is no built-in drop-down ladder - you need to do it yourself. The installation of the hatch can be done by hand. You can even make your own product. Hold the structure on the hinge ceiling. To keep the room warm, if the attic is without heating, one or more layers of insulation are placed in the hatch.

Construction of the hatch [do it yourself]

The homemade design will not be significantly different from the factory models. The only caveat is the finish. Drawings are presented on the Internet, and a small amount of tools and materials are required for manufacturing. To make a simple hatch, you need several sheets of plywood and a 5x5 cm timber. You can choose another thickness. This hatch will not have any insulation materials inside.

Stages of work:

1. The first step is to choose the place where the hatch will be located. Then its optimal dimensions are determined. Add about 9 mm to the numbers on each side. This will allow you to fold the lid in the future without noise and squeaks.

2. Next, cut the wooden block into pieces according to the dimensions of the hatch. Then grooves are made at each end of the bars, they are lubricated and connected into a rectangular structure. Most often, the dimensions of the hatch are such that it is exactly a rectangle.

4. In order not to lead the diagonals, the kerchiefs are screwed on. After that, you can try on-install the hatch in the opening under it.

5. In order for the hatch to close, a latch is cut into the top cover. The structure will open with a handle, it is fixed on the lid.

6. Then the product is fixed in the opening, for this ordinary hinges are used.

A more complex design includes a beam with a thickness of 10 cm, as well as insulation materials inside and a rubber seal around the perimeter.

The attic in the house can be used for different needs. Of course, comfortable access must be organized to it, for which a ladder is needed. It can be installed on the outside of the building or inside it. The latter is easy to use and more popular. There are many ways how an attic staircase can be made with your own hands. Before describing how to make an attic or attic floor, you need to choose a constructive solution suitable for your home.

Varieties of attic and mansard stairs

Let's take a look at the most popular options for attic stairs.

The latter type is more often used for a while or in the case of rare use of the attic space. But the most practical and compact will be a folding design with a hatch.

What to look for when making a ladder yourself?

The first thing that should be ensured when building an attic or attic staircase with your own hands is safety. The staircase system must have adequate strength and reliability.

The dimensions of the staircase are also important: the more it slopes, the more space it takes up. The most suitable is the angle of inclination equal to 60-70 °. Although with constant use, it is recommended to make it 45 °. Steps with a height of 20 cm and a depth of 30 cm are considered standard. The width of the stairs should be comfortable, as a rule, it is about 70 cm. It is not recommended to make such stairs more than 3 m in height, since a higher structure will not have the necessary rigidity and reliability.

It is advised to make a structure with the number of steps from 10 to 15, and leave the distance between them 19 cm. The recommended step thickness is 2 cm. They should be placed strictly parallel to the floor surface. For greater safety, anti-slip pads are glued to the steps.

Important!The ladder to climb to the attic floor must be able to withstand a load of 150 kg.

The hatch also has its own recommended parameters. The following dimensions are considered standard: width 70 cm, length 120 cm. Smaller dimensions will make the opening not comfortable to use, and large ones will increase the heat loss of the room. For an unheated attic, it is advised to make the hatch heat-insulated and vapor-insulated.

Where is the best place to place the stairs?

The staircase should be located so as not to interfere with household members. Therefore, you should not mount it in the kitchen; it would be more expedient to use a corridor or hall for this purpose. It is also worth considering the size of the room. Sometimes a staircase can be used as an interior detail, then it is not hidden in a hatch.

Important! It is advised to pre-draw the future staircase, then it will be easier for you to understand which place will be the most suitable for its installation.

DIY single-section design

The easiest to climb to the attic floor will be a one-section design solution that will be fixed in one place. In order to build a staircase with one section, you need two wooden planks. The length must be suitable for obtaining the appropriate angle of inclination, and the thickness must be at least 5 cm.

The steps can be secured with bowstrings or stringers. Bowstrings are grooves made by a router in the end plate. A kosour is a horizontal platform cut out on a board, on which a step is then placed. The steps are fixed in place by means of metal screw pins. A handrail provides a comfortable rise to the floor. For their manufacture, a polished solid bar of the appropriate length is used. Depending on the location of your staircase, the railings can be on one side or both. To make the structure more reliable, it is worth adding vertical connecting beams to it.

Manufacturing of a one-section attic staircase.

We make a hatch

Installation and manufacture of the hatch is also an important aspect of the work. It will prevent cold air masses from entering the house. This is the main reason for equipping staircases with a hatch. To make it, you need 50x50 bars and a sheet of plywood.

Work order:

- Determine a suitable location, taking into account the size margin of 0.8 cm, so that the hatch closes normally.

- The bars must be cut into four parts according to the dimensions of the hatch, and holes must be cut out along the edges.

- For each groove obtained, you need to apply glue and fasten the bars with self-tapping screws.

- To keep the diagonals, headscarves are screwed on.

- The next stage is plywood fastening.

- The finished cover is tried on, and then the latch is installed on the opening.

- In order for the lid to open without interference, a handle is installed in the opening.

Important!The resulting structure should open easily and without hindrance.

An example of a homemade attic hatch with a metal-plastic cover.

The staircase, equipped with a hatch and leading to an unheated attic floor or attic, has design features. The opening for the construction of such a structure with a hatch must be insulated. In the manufacture of the hatch, a layer of thermal insulation and vapor barrier is placed on the plywood. The top is still reinforced with a vapor barrier film. After the completed work, the final stage remains - decoration. It is made similar to the ceiling finish. At your request, the color scheme can contrast with the walls. Sometimes, instead of plywood sheets, metal sheets are used, which must be painted with paint that is suitable in color and performance.

How to make a two-section folding staircase?

The staircase structure of two sections is quite simple to manufacture and does not imply the use of a complex mechanism. This design will be optimal for execution by a person without special skills in construction.

The first thing you need to do is make a simple ladder. After manufacturing, it is carefully adjusted according to the dimensions, and precisely observing the angle of inclination. After that, the finished structure is cut into two sections, which need to be attached to each other using awnings, and you get a folding ladder. You just have to make the installation of the folding structure to the cover of your hatch.

The foldable ladder structure can be supplemented with an auxiliary cable mechanism that will facilitate the disassembly and assembly of the system. Install the locking hook to prevent the folded structure from opening. To fix it, a loop is installed at the junction of the sections, and a hook is mounted on the wall at the required distance from it. The design is ready for use, but it will always be in sight, which is considered its disadvantage. If this moment is important to you, then you can use the following recommendations. Execute a three-section staircase, which is made according to the above technology. Such a ladder can be easily hidden in a hatch.

Making a folding ladder to the attic.

Manufacturing of the hinge mechanism

When making a folding structure, the opening mechanism is important. You can make it yourself using the following materials:

- metal corner;

- part of a sheet of metal;

- two strips of different lengths;

- bolts;

- clamps;

- set of drills;

- drill;

- jigsaw;

- teski;

- malka.

Manufacturing procedure:

- First, the ladder is drawn on a sheet of cardboard with an indication of the future angle of inclination in the open state.

- Then the layout is cut out of cardboard to check all sizes.

- On the metal strips, they measure the places for the holes where the hinge will be attached. The hole must match the size of the bolt.

- Parts are assembled and pulled together.

- Use a bevel to measure the desired angle. Then open the mechanism to the resulting angle.

- Mark on the metal the part that will overlap with a corner during opening. Use a jigsaw to cut it out.

- Round off the corners of the strips and remove unnecessary lengths to prevent the strips from snagging, allowing the mechanism to operate.

- When the excess metal has been removed, the corner will rest in the right place. You made the first hinge.

- The second is made by fastening the parts with clamps in pairs, with special tools for better fixation. Drill a hole and place a bolt in it.

- Then a second hole is made.

- The workpieces are twisted with two bolts. Then they can be aligned, giving them the same shape.

This is how all parts of the hinge are performed to obtain the same elements. The completed mechanisms are attached to the hatch and try on whether it matches the opening. They do it like this: if in a fully open state it does not touch the edges of the opening, then the dimensions were taken correctly, and the hatch is ready for installation.

Manufacturing of a folding ladder structure

The construction of folding ladders has a similar technology to folding ones. At the first stage, a ladder is made according to the technology described above. Then choose the more suitable of the two options for yourself:

Stationary Structures and main components of stairs