Renovation work in the bathroom is fraught with inconvenience. The small area of the room limits the working space, there is a high risk of damage to bulky plumbing. You need to act carefully and for sure, because alterations will not be cheap. Particular attention should be paid to solving the question: how to fix the bathtub to the floor. There are various ways to install a water reservoir, but sometimes it is not easy to decide which method is the most optimal.

At first glance, it seems that the bath itself is quite stable and does not require additional measures for reliable fixation. This opinion is partly true for heavy cast iron baths, which are held in place by their own weight, which reaches 180 kg.

For products made from this material, careful preparation of the floor is important:

- execution of a concrete screed with constant control of the horizontal level;

- use as a final coating of tiles that can withstand significant weight.

If all work is carried out in compliance with the technical requirements, fixing the bath to the floor is reduced to installing a drain and overflow system. Such a tank is often installed in the middle of a room if the bathroom is significant in area, and the non-standard arrangement of plumbing is provided for by the project.

In the case of a tight abutment of the cast-iron bathtub to the wall, it is necessary to ensure reliable waterproofing of the space between the side and the vertical surface. Otherwise, water will seep and accumulate on the floor.

In some cases, it is necessary to screw a heavy cast iron bathtub to the floor. If the floor is covered with glossy slippery tiles, then the bathtub needs to be fixed.

For better measurement accuracy of the horizontal position of the bathroom, the level is placed diagonally on the sides.

The cast iron bath is held in place by its own weight

Features of installing bathtubs made of metal and acrylic

Metal and acrylic bathtubs have gained well-deserved popularity. They are distinguished by their lightness of construction and are affordable. It will not be difficult to choose the right length of plumbing. Considering the modest parameters of bathrooms in housing built 20-50 years ago, this is very important. Indeed, it is much easier to install a bathtub that is supported on three sides. You don't have to think about how to use the space between the tank and the wall.

Screwing the feet of the acrylic bathtub to the floor

To ensure reliable fixation of the bath, installation is carried out in two planes:

- attach the legs to the floor;

- provide a tight fit of plumbing to the walls - two, ideally - three.

In practice, this task is implemented as follows:

- Prepare the floor covering.

- The distance from the sides of the bathtub to the walls is no more than 3-5 mm. Therefore, the length of the product is determined in advance, even before the purchase is made.

- Installation of a siphon and an overflow system is carried out. The work must be done before the final fixation of the bath.

- It is imperative to check the horizontal level. The device is placed on the sides of the bathtub, because the bottom of the tank is slightly sloping to ensure smooth drainage of water - this feature is provided initially.

- Install the bath on supports, fix the legs.

- The last stage is laying the tiles on the walls and installing insulating borders between the bathroom and the vertical surface.

Fixing an acrylic bathtub to the floor is not significantly different from fixing a metal one. But there are features, primarily related to the properties of materials.

If it is necessary to install the bathtub at a higher level, brickwork is performed in the places where the legs will stand

After installing the supports, it is advisable to additionally fix the metal bath with polyurethane foam. After solidification of the material, if necessary, cut off the excess. Most often, a metal bathtub is tiled to give the design aesthetics and completeness. If such a design is provided, it is not necessary to remove the foam - it will serve as a sound and heat insulator.

The acrylic bathtub is attached to the wall using special hooks - as if hung. So the plumbing will not "play" because of the constant displacement of the center of gravity, and regular use will not affect the durability.

Steel bathtubs need sound and heat insulation. This work must be carried out before securing the tank.

How to properly fix the bathtub to the floor

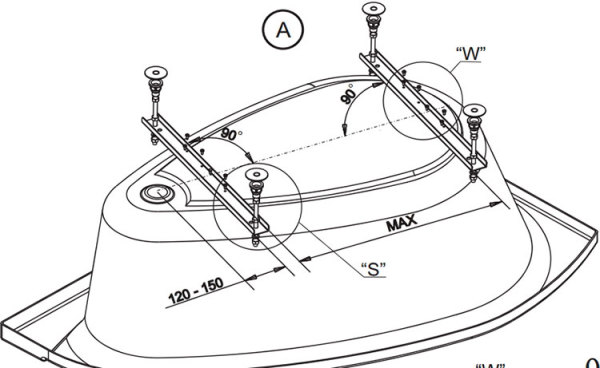

The fixation of the bathtub to the floor is carried out with the help of legs and special fasteners, which usually come with plumbing fixtures. The supports are mounted according to the attached instructions - models from different manufacturers have their own characteristics.

Assembling acrylic bath legs

Among the general requirements are the following:

- the legs are attached to the base of the bath with bolts - during installation it is important not to drill through the metal or acrylic. For this, a limiter is installed on the drill;

- be sure to use protective pads to prevent damage to the floor;

- self-adhesive pads are fixed by turning the bath upside down;

- after installing the bath, adjust it in height and check the horizontal level.

Bath adjustment with water level

All fasteners must be securely connected to each other. Work surfaces are degreased before installation. Before filling the bath with water, it is necessary to check the tightness of the drain - it can be broken due to errors in the installation of plumbing.

After filling the space between the bathroom and the wall with polyurethane foam, water should be drawn into the tank and left until the material has completely solidified.

The installation elements of the acrylic bathtub are located in the immediate vicinity of the drain hole and at the end of the product

High-quality repair work is the lot of professionals. The independent implementation of a multidisciplinary set of measures for the capital transformation of housing is a difficult task. Errors and shortcomings are inevitable, which can negatively affect the operation of expensive plumbing and lead to its premature failure.

The services of a team of true masters of their craft are not a luxury, but a reasonable necessity. Quality, responsibility for the result, warranty period are quite legal requirements. And most importantly - feasible by bona fide contractors.