As a rule, much lower operational requirements are presented than for load-bearing walls. Therefore, for their construction, thin-sheet materials are often used, primarily drywall. However, the price for such convenience is relatively low strength, low heat and noise insulation.

If the first is not so important for the internal walls, then the second two points require an effective and prompt solution even at the construction stage. We will tell you how designed and installed sound insulation of plasterboard partitions, what materials and technologies are involved in this process.

Theoretical basis

Before installing insulation layers, it is necessary to understand the nature of the functions that they should perform, as well as some basic terminology.

Sound insulation is a set of measures and technical solutions aimed at reducing the level of noise coming from outside.

The noise itself is conventionally classified into three groups:

- Impact - arise as a result of mechanical action on the surface and initially spread in a solid medium (impacts, knocks, squeaks, etc.)

- Structural - formally they are a kind of percussion, but due to their specificity they stand out in a separate group. They arise as a result of the relative mixing of structural elements relative to each other, which is typical, for example, of frame houses. Constructional noises include, in particular, parquet creaking.

- Acoustic - the most common group, which includes all sounds emanating from external sources and falling into the structure of walls and partitions from the air. Examples of acoustic noise include human voices and music.

If sound insulation is a general concept that characterizes different areas of activity, then noise absorption- a narrower, physical sphere, indicating the degree of dispersion of sound waves in a solid medium.

In practice, both of these phenomena are inextricably related to thermal insulation as a way to prevent heat loss as a result of heat exchange with the external environment.

Therefore, the modern building materials market includes many combined means that provide comprehensive sound and heat insulation of surfaces, although there are also "highly specialized" substances. You can learn more about them and other insulating materials in the next section.

Which sound insulation material to choose?

A plasterboard partition with high-quality sound insulation is a complex complex design, in which one or two insulating layers cannot be dispensed with.

You will need the correct choice of the drywall sheets themselves, filling the partition, frame materials and even fasteners.

So, the minimum set that will allow you to extinguish up to 30% noise, includes:

- Gypsum plasterboard GKL (GKLV) PK 9.5 or 12.5 mm thick - is located in two or three layers with gaps filled with sound-insulating material, with or without an air gap.

- The main sound-insulating layer is a sheet or roll material located in the intervals of the "pie". The most widespread are: ecowool, basalt and mineral wool, felt or other substances.

- Additional sound-insulating layer - it is used less often and involves gluing the inner support surfaces with a cork, rubber-cork or foil backing. For plasterboard partitions, the backing is not very effective.

- Frame - is a supporting structure made, as a rule, of an aluminum profile. Serves for fixing drywall.

Such an approach to soundproofing the partition will not bring the desired effect, even if the structure is multi-layered. This is due to the vibrational nature of the sound waves, which propagate perfectly over communicating surfaces of high hardness. In this case, the sheets themselves, and the frame, and the frame fasteners act in their role.

Such an approach to soundproofing the partition will not bring the desired effect, even if the structure is multi-layered. This is due to the vibrational nature of the sound waves, which propagate perfectly over communicating surfaces of high hardness. In this case, the sheets themselves, and the frame, and the frame fasteners act in their role.

To reduce the impact of this chain will help following measures:

- the use of not drywall as an internal support sheet, but OSB slabs;

- the use of microporous rubber gaskets between sheet materials and the floor, ceiling, walls;

- gluing frame profiles with soundproof tape materials;

- replacing the aluminum profile with a bar made of durable types of wood, for example, beech;

- in the walls of special soundproofed dowels.

Correctly performed complex of these actions will provide attenuation of at least 80% of noise, which means that voices, music at an average volume and the sound of movable furniture behind the partition will be almost inaudible.

Installation rules

The main sound-insulating material is located between the supporting surfaces of the partition, which means that there can be several layers of it.

The most widespread are fibrous materials, which are supplied in rolls or sheets, depending on the specific gravity of the substance. The form of manufacture also imposes some specific requirements for installation.

Soft roll insulation is usually cut into sections equal to the height of the frame gaps. One of the sections will have to be cut and lengthwise. All sizes fulfill with a margin of 5-10%, to ensure tight fixation of the insulator in the gap.

In the case of installation of sheet soundproof materials, they may need to be precisely molded, which is important, first of all, with a low elasticity of the substance.

If there is an air gap behind the insulator layer, installation of plates on the frame is permissible preventing sheets from falling out of the gaps.

Some nuances may arise with the simultaneous installation of dissimilar noise and heat insulation layers. In this case, the first, starting from the side of the sound source, is the heat-insulating layer. As a rule, its width is chosen in accordance with the width of the frame.

After that lay plastic wrap and proceed to the installation, for which it is most convenient to use sheet materials. They are located in the frame of the other side of the partition or in the free space between them, for which sometimes auxiliary fasteners may be needed.

Selecting wall thickness

It is impossible to unequivocally answer the question of the optimal thickness of the wall with sound insulation, because in each specific case a number of factors are taken into account. on the specifics of materials and place of installation.

Here are some main options with a range of average thicknesses:

- Without a separating layer - consists of two plasterboard layers (about 25 mm), a frame or two separate frames (about 50 or 80 mm) filled with an insulator, and an air gap (about 25 mm), totaling 90-150 mm.

- With one inner dividing layer of - in addition to the layers described, it also takes into account the thickness of the intermediate board itself (approx. 15 mm) and another interlayer. The total thickness of the partition is 160-200 mm.

- With two separating layers (multilayer construction) or with additional insulation - they assume a margin of 50 or 80 mm, respectively, which is spent on the installation of another OSB plate with an interlayer or sheet insulation. The range of thicknesses for the first case is 210-250 mm, for the second 240-280.

In addition, the thickness can be manually adjusted, depending on the architectural and design solutions of the premises.

The design and implementation of high-quality soundproofing of interior drywall partitions is a complex multi-level process that requires responsibility, attentiveness, and accuracy. But in the case of a competent approach to work, you can enjoy the complete silence and comfort of the rooms.

Find out what soundproofing materials can be used for walls in an apartment from the video:

Sound insulation of internal partitions is a procedure that makes it possible to increase the comfort of living at home and significantly reduce the amount of noise entering the apartment.

Which partitions are better for noise insulation?

Most often, the question of creating sound insulation inside an apartment arises in new monolithic houses. In new buildings, apartments are rented either without internal walls at all, or with erected partitions from a tongue-and-groove or foam block - the worst option in terms of sound insulation.

Partitions made of tongue-and-groove and foam block always require additional sound insulation

A significant drawback of such partitions is a strong degree of resonance - they conduct sounds well from apartments above and below. This is what leads to an increase in the noise level from the neighbors' apartments - and such housing cannot be called cozy. Noise insulation between rooms is also very weak: about 37-41 dB, depending on the material used (with the values required for comfortable living of at least 52 dB).

The best solution in such a situation would be to dismantle the ringing blocks and build new gypsum board partitions with sound insulation. Ultimately, it will come out cheaper and save valuable square meters of your apartment!

The fundamental device for noise insulation of partitions

The partition is based on a KNAUF metal profile with a layer of sound-absorbing materials, sheathed with gypsum fiber and drywall sheets on each side. The thickness of the base partition is 10 cm, which is comparable to the thickness of conventional block partitions made of tongue-and-groove or foam concrete.

Noise insulation of interior partitions is one of the activities of the MontazhZvukService company. We have been producing such works for many years and can boast of a large portfolio. We also recommend that you familiarize yourself with the table below - it contains prices for typical noise insulation of partitions.

Prices for noise insulation of partitions per m 2

| Type of work: | Description: | The cost of sound insulation "turnkey" |

| Basic baffle (10 cm) |

A plasterboard partition on a KNAUF profile 50/50 mm with sound insulation inside is a standard solution for sound insulation between rooms. Noise reduction 55dB! | ~ 3700 rubles / m2 |

| Reinforced baffle (15 cm) |

A partition on a wide profile of 100/50 mm with two layers of sound insulation inside. It is used for enhanced sound insulation (for example, between two bedrooms or between the living room and the nursery). Soundproofing up to 60 dB! | ~ 4000 rubles / m2 |

| Partition on split frames (16 cm) |

Two threads of the frame are collected, not in contact with each other. The circuit is used for the most difficult cases (home theaters, recording studios) Sound insulation up to 67 dB! | ~ 4200 rubles / m2 |

When calculating the sound insulation of the partition, it is necessary to pay attention to several factors. First of all, this is the area of work to be performed. You also need to decide what level of sound insulation the partition should provide - for apartments, the MontazhSvukService company offers several options that differ in the degree of sound protection.

In addition to significant loads on interfloor floors, laying brick walls is associated with serious time costs and requires professional skills.

If you want to create, then an imitation for a brick niche can be created by finishing a block or frame structure with brick tiles. Corner elements of artificial stone will allow you to achieve a complete illusion of the thickness of brickwork or natural stone.

Concrete

Suitable for construction with a density of 600-800 kg / m³, a thickness of 80-100 mm. The thinner thickness is insufficient in terms of sound insulation and resistance to cantilever loads. However, the walls of foam blocks require plastering. For this reason, it will be difficult to create a small decorative niche, since you will have to saw off blocks to size, plaster the surfaces.

Expanded clay concrete partition blocks are moisture resistant and durable, but do not differ in the stability of geometric dimensions. Such masonry is done only by professionals, and in any case, you will have to level the surfaces with rather thick plaster layers.

From tongue-and-groove gypsum boards

Gypsum tongue-and-groove slabs are larger than foam blocks, but decorative niches can be created with them. Thanks to the groove-tongue connection, the structures are stable. They do not need reinforcement, only anchoring to the walls and reinforcing the corners with plaster corners made of galvanized steel. The downside of the material is that it is difficult to saw. Therefore, when fitting in size, it is necessary to remove grooves and ridges, and then reinforce the masonry with reinforcing bars or plates. But the walls made of foam blocks let steam through, that is, they breathe. Moreover, gypsum contains water and acts as a humidity regulator in rooms with normal humidity.

Tongue gypsum slabs weigh significantly more than concrete blocks, therefore they are suitable only for houses whose floors are designed for a distributed load of more than 800 kg / m2.

Another disadvantage is high elasticity. Because of it, a drum effect appears - a relatively low level of sound insulation at frequencies of 100-200 Hz.

Partitions with a pocket for a sliding door are usually made of plasterboard. It can be based on a factory pencil case made of special section profiles. The design provides the ability to adjust the height of the web.

Porous ceramic

Porous ceramic blocks are 2–2.5 times lighter than bricks and at the same time hold fasteners well. If you use chemical anchors, then even hinged plumbing can be mounted on a 130 mm thick wall.

The large format of the blocks accelerates the laying, grooves and ridges on the side ends strengthen the partition, and the ribbed surface provides a reliable adhesion to the plaster layer.

The disadvantages of porous blocks include a relatively high water absorption. This problem can be solved with a water-repellent primer and cement plaster.

Plasterboard

Practically does not load the floor, does not require time-consuming and allows you to lay wires and pipes hidden without any problems.

In recent years, instead of the usual fastening with self-tapping screws, punching is more often used: a hole with bent edges is made in two contacting walls of the profiles with a special tool resembling pliers. Fixation with a cutter speeds up the installation, moreover, there are no protruding screw heads on the frame, and the drywall sheet falls on it perfectly evenly. However, when fastening with a cutter, it is more difficult to correct mistakes, moreover, it is less durable, therefore it is important to observe the required pitch of the screws - 250 mm.

Redevelopment Legal Notice

With the housing inspection authorities. If the design calculation shows an increase in the load on the floor, then it will be difficult to obtain permission, since the technical opinion of the house designer will be required.

- Redevelopment, which affects load-bearing walls or unloading non-load-bearing partitions, can only be started after obtaining permission from the housing inspection authorities.

- When redeveloping, it is impossible to increase the load on the floors in excess of the permissible for the project (calculation by bearing capacity, by deformations).

- It is difficult to agree on the replacement of the partition with a heavier one.

- They will not allow redevelopment, in which your bathroom will be above the kitchen or living room of the apartment below. This rule also works for the arrangement of apartments in monolithic new buildings, where new walls of wet zones are erected according to the floor plan.

How to avoid mistakes during installation

A common mistake when arranging interior partitions is their incorrect location. The owner of the apartment may incorrectly assess the dimensions of the premises (for example, a dressing room), the architect may not understand the wishes of the customer, the foreman may misread the plan, the workers may see the “wrong mark”. The wall has to be dismantled and rebuilt, wasting time and increasing costs. Therefore, the owner of the apartment, together with the architect (designer), is highly desirable, armed with a plan and a tape measure, to come to the object to control the laying of the first rows.

| Material | Corpulent red brick | Slotted brick red | Porous ceramic block | Aerated concrete block | Hollow claydite concrete block | GWP hydrophobized |

|---|---|---|---|---|---|---|

| The smallest possible thickness of the partition, mm | 65 (brick by edge) | 120 | 80 | 50 | 90 | 80 |

| Optimal thickness of the interior partition, mm | 120 (in half brick) | 120 | 120 | 100 | 120 | 100 |

| Masonry mortar | Cement-sand grade not lower than М200 | From ready-made cement mix, for example Porotherm | From ready-made cement mix (KNAUF LM2, "Blockstar FIX", etc.) | Cement-sand grade not lower than М200 | Ready plaster (KNAUF-Perlfix, Volma Montage, Ivsil-Plast, etc.) | |

| Density, kg / m 3 | 1600–1900 | 1000–1400 | 750–900 | 400–600 | 950–1000 | 1100–1250 |

| Water absorption,% | 6–14 | 6–14 | 14–18 | 50 | 10 | 6–8 |

In most apartments, interior walls are erected from tongue-and-groove, foam concrete or cinder blocks - materials that are extremely unsuccessful in terms of sound insulation.

Why are these materials chosen for interior partitions? The thing is that it is convenient for builders to erect such walls, and they are erected quite quickly: in a couple of days you can erect all the walls, and then make good money on their plaster. The low noise insulation of such walls and their high ability to transmit noise from the adjacent apartments of the workers, as a rule, do not care, since they will not then live in the apartment being repaired. "Nothing personal - it's business!"

What is the best way to build interior partitions for better sound insulation?

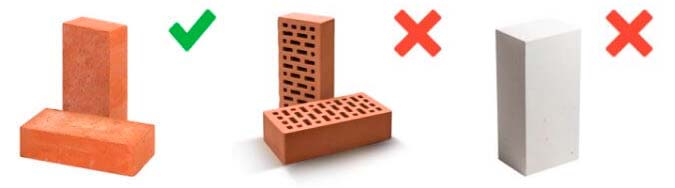

Partitions are single-layer and multi-layer. Single-layer walls are made of blocks, and multi-layer ones are frame sheathing structures, for example, from plasterboard. If we talk about partitions made of homogeneous materials, then only materials with such as solid red brick, expanded clay concrete blocks will provide high sound insulation.

Expanded clay concrete blocks covered with sand are used for interior walls in recording studios

Noise insulation of a brick partition

Partitions made of red solid bricks will have good sound insulation (hollow or sand-lime bricks are not suitable). Red brick has a high surface density and good internal losses.

The wall should be thick half brick(not a quarter) and must be plastered on both sides (total thickness ~ 140 mm). It is important not to skimp on cement mortar.

Building regulations prohibit the construction of brick walls in apartments

We could assume that we have found a suitable material, if not for one moment that makes it impossible to use solid bricks in apartments! Current building codes prohibit brick partitions in apartment buildings - the floors are simply not designed for such a load!

Sound insulation of interior walls made of other materials

The rest of the building materials, passing by weight, have low sound insulation and do not provide standard values.

For example, the density of tongue-and-groove blocks (gypsum) is 1100 kg / m 3. The calculated sound insulation of a partition made of a plastered tongue-and-groove with a standard thickness of 80 mm is ΔR w = 40 dB.

Sound insulation of walls made of foam concrete or aerated concrete blocks has even weaker sound insulation than walls made of tongue and groove. The density of D400 foam concrete is only 400 kg / m 3, i.e. even less than a tongue-and-groove! A foam concrete wall with a thickness of 100 mm has an insulation index of only ΔR w = 37 dB.

Low noise insulation of such walls is also caused by undesirable resonance phenomena in the range of 500-800 Hz (the middle of the speech frequency range), which significantly reduce the sound insulation of household noise.

Indirect noise transmission to block walls

Another unpleasant feature of tongue-and-groove walls or porous concrete is their strong re-emission of noise from the lower and upper neighbors. Due to the low weight of such walls, sounds from massive floors are very well transmitted to them. In addition, gypsum plaster has very low internal losses (as a test, you can knock on the plaster wall and feel its "sonorous"), which also enhances the re-emission of structural noise.

Subjectively, after dismantling all internal walls, the noise level is approximately halved!

Installation of interior walls from blocks cannot be performed without rigid connections with the existing structures of the house, therefore, it will not work to completely exclude the transmission of vibrations to them.

A noticeable reduction in noise can be obtained if the partitions are not brought up to the ceiling overlap by 10-20 mm. The gap should be filled with mineral wool or other damper and the joint should be sealed. Such a measure will reduce the transmission of noise from above to the partitions.

An example of a vibration-insulated junction of a partition to the ceiling.

In no case should you use polyurethane foam, which is very light and has a closed cellular structure, therefore it has neither reflective nor absorbing properties. At the same time, foam is an acoustically rigid material and perfectly transmits vibrations.

Noise insulation of interior walls from a groove (or aerated concrete) is insufficient. Such partitions often have to be additionally soundproofed.

Undertaking repairs, the owners sometimes plan to divide a room that has a large area. In the newly formed room, you can equip a study, a nursery or a bedroom. At the same time, it is necessary to think over the protection of the received premises from noise, because peace and quiet are one of the factors of comfortable rest or productive creative work. The choice of the best option for soundproofing interior partitions will give the desired effect, increase the convenience of the family.

As you know, the thicker the wall structure, the more sound insulation it is characterized. However, a rational approach is a design device that will provide the maximum level of sound insulation with the smallest parameters of the thickness and weight of the partition. Thus, there are three ways to reduce the noise level:

- increase the massiveness of interior partitions;

- use sound-absorbing materials in the structure;

- to carry out sealing of the assumed paths of penetration of sound waves.

Interior partitions: structures and materials

Partition structures are divided into two groups:

- single-layer;

- multilayer.

Single-layer walls separating the interior space of the house are made of various dense homogeneous building materials that are rigidly bonded to each other with mortar. It can be bricks, blocks, tongue-and-groove slabs, expanded clay concrete. The sound insulation parameters of each material depend, first of all, on the mass, and in order to ensure the desired level of this indicator, the wall thickness can be increased. However, this approach increases the load on the floor and foundation, reduces, albeit slightly, the area of the room.

If we recall physics, then sound waves, propagating, encounter an obstacle (partition) on their way and are reflected or refracted. Porous structures are capable of absorbing a wave that is scattered in the depths of the material. Therefore, preference is often given to multilayer partitions, consisting of at least two to three layers.

In this design, materials of various structures alternate: dense and light. They differ greatly in characteristics and are not rigidly linked to each other. The former, for example, represented by brick or plasterboard, have a high reflection coefficient and perform a soundproof function, the latter, soft (mineral wool), provide sound absorption. Such a union is effective and creates optimal conditions for protecting premises from noise, since one layer of the structure reflects the sound wave, the other absorbs.

To compare the characteristics of various materials, an indicator such as the sound insulation index of partitions is used. SNiPom regulates the sound insulation of interior partitions in one apartment. This parameter is not less than 43 dB.

However, as practice shows, recently the number of powerful sources of noise has increased significantly: home theaters, air conditioners, hoods and other household appliances. An increase in the background noise does not contribute to comfortable living and it is advisable to equip the interior partitions, bringing the sound insulation index of the structure to at least 50 dB.

How to soundproof a plasterboard partition

Drywall is a material that conducts sound well, therefore, the thickness of sound insulation is recommended to be at least 15 cm and multi-layer. Work begins with the installation of a frame under a partition made of a metal profile: vertical posts, guides, stiffeners and sheathed with drywall sheets. On the other side of the cladding, a similar frame is mounted, their independent installation, which does not provide for a structural connection, will prevent the formation of sound bridges with opposite surfaces of the partitions.

Next, a soundproofing material is laid. These can be insulating membranes, the popular Isover, or the usual mineral wool. And again sheathing is performed with sheet material. When installing soundproofing walls made of plasterboard, an anti-vibration tape is used, its use will contribute to the protective function of the structure from noise.

Treatment of drywall with antiseptic agents and a primer is an important step in the process of making partitions, it will ensure the reliability and longevity of the newly built interior wall. Further work is related to filling, grouting and decorative finishing of the structure.

Carrying out soundproofing of frame partitions, other materials have also been used. A striking example is the Soundline-dB acoustic triplex. It consists of two gypsum fiber sheets, they are weighted and have high moisture resistance. Each of them has an 8 mm thickness, they are connected with a layer of a special sealant, characterized by elasticity. The material is used for soundproofing frame-type partitions.

The choice of material for soundproofing partitions of a wooden house

Wood is a traditional and favorite material of the Russian developer. Therefore, a huge number of country houses are built from logs and beams. As for the partitions inside the building, they are made extremely rarely from logs, since such a wall not only makes the structure of the whole house heavier, but also takes up part of the usable area.

They are most often made frame-panel, from a bar, from a board. Wood conducts sounds well, so if you don't worry about soundproofing wooden partitions, then every sound will be clearly heard in the next room, and even a quiet creak will interfere.

The most common and effective option is the frame construction of partitions, consisting of several layers, like a pie. For cladding, wooden lining, boards, fiberboard, drywall are used, and fiberglass, mineral wool and other materials are used as an internal sound-insulating layer.

How to make soundproofing of tongue-and-groove partitions

Tongue slabs are another building material that is often used in the installation of interior interior walls. The panels are made on a gypsum basis; by themselves, they have a good sound insulation coefficient - 42 dB (with an 8 mm thickness of the product). But still, this is not enough.

Additional sound insulation is performed using materials with a sound-absorbing effect. These are special membranes that are glued to the surface of the board, fixing it securely. Any construction sealant can be used as an adhesive. To increase the level of noise protection of the room, the membrane is attached to both sides of the partition. Thus, they achieve an increase in the sound insulation coefficient by almost 30 dB.

In ensuring the sound insulation of the premises, the choice of material and the competent implementation of the corresponding complex of works play a primary role. But do not forget that only soundproofing a plasterboard or wooden partition will not give the desired effect. It is advisable to carry out measures for the sound-absorbing processing of the outer walls, if the room has a window facing the street, take care of a double-glazed window, good adjustment of the fittings.