If the basement of the house is high, it is necessary to equip the porch when creating the building. It must be durable and reliable. Therefore, when arranging steps, they must be guided by the established rules and regulations. Create do-it-yourself concrete porch according to the established technology, almost every master who has minimal skills in construction will be able to.

There are many options for decorating the entrance to the building. The main thing is that the porch is combined with the general style of the facade. In this case, you can choose various decorative elements. The main thing is that the structure is strong, safe and durable.

Assumes the fulfillment of all existing requirements. Most often, such a structure is designed together with the plan of a cottage or country house. However, in some cases it is required to attach the steps separately. If the porch was not included in the plan or it is required to reconstruct the old building, it is necessary to approach such work very responsibly.

Various adverse consequences can be expected if building codes and requirements are not followed. Facade walls adjacent to the structure may crack. In this case, additional costs will be required to strengthen them.

Also, if improperly installed, the porch itself may sag. In this case, it will become unsafe to use the steps. Their topcoat may also peel off. In this case, the porch will lose its decorative effect.

When creating a plan for a future extension to the house, you will need to take into account the dimensions of the building itself. The steps should fit harmoniously into the overall exterior. They should not be too small or oversized so as not to look ridiculous.

Varieties

It can have various configurations. When choosing a shape, the geometry of the facade in the entrance area is taken into account. The porch can be semicircular, trapezoidal, square or rectangular. The choice depends on the overall design of the building from the outside, the style of decoration.

The strength of the structure does not depend on the shape of the porch. However, experts say that it is better for novice craftsmen to give preference to structures with corners. It is quite difficult to create round steps without sufficient experience in carrying out construction work.

The porch can also be closed, open, or have a veranda configuration. It can also be equipped with or without railings. If the ascent is steep and the staircase is narrow, handrails are recommended. This will ensure the safety of ascending and descending steps.

Organization of construction

Considering, how to make a porch out of concrete, it is necessary to properly organize the entire workflow. It is better if the steps are built together with the building. However, if it is impossible to carry out this process, it is necessary to take into account a number of recommendations.

The top step should be 5 cm below the door level. This is stipulated by the relevant rules. The number of steps is chosen according to the height from the ground to the door. Their slope and size should facilitate comfortable and safe movement of people. A top deck is optional. If it is convenient for the owners to create a structure with such an element, this will be a good solution.

Construction includes several stages. The project is created first. Next, the site for installation is cleaned. Next, the formwork is mounted. After that, concrete pouring takes place. Finishing work completes the construction process.

Design

The width of the porch should be at least 80 cm. If two people move along the steps at once, this figure increases to 1 m. The angle of inclination of the extension should not be more than 45º. Better if it is 30º. For convenience, the number of steps should be odd. Each of them must be at least 25 cm wide.

The height of the steps, depending on the other selected parameters, should be in the range from 120 to 200 mm. The upper deck must be sized so that the door can be opened freely. After taking into account the listed standards, it is necessary to calculate the amount of concrete and reinforcement.

Tools and materials

It is necessary to create according to the project. The concrete can be ready-made. If you use this material, its grade could be M200. When self-mixing the dry mix, it is recommended to purchase more durable cement. Material with a grade of M400 is suitable. A sand and gravel solution is kneaded from it.

You will also need reinforcement with a diameter of 6.5 mm. It is tied with wire. The formwork is created from planks. Its frame is made of beams. You will also need nails, waterproofing (roofing material).

Several instruments need to be prepared in advance. You will need a hammer drill, a grinder, a special concrete compactor. The boards are cut with a saw. In the process, you will need shovels (shovel, bayonet). The mixture is kneaded in a special trough. It is also recommended to prepare a hammer, spatulas, level, tape measure.

Preparatory process

Having chosen the optimal configuration of the future structure, it is necessary to consider step by step instructions. Do-it-yourself concrete porch should be equipped in accordance with the developed methodology.

The construction site must be prepared. If there was an old porch here, it will be completely dismantled. Next, you need to make the foundation. Without it, the porch can sink. To do this, you need to dig a hole. The depth should be 20-25 cm, the width should be in accordance with the size of the porch (should be more than 2.5 cm). The steps should be wider than the door leaf. They must exceed this figure by 15 cm. The upper platform must be at least 1 m wide.

The foundation must match the depth of the base of the house itself. Crushed stone is poured onto the prepared area. It is necessary to lay raw sand on it. It is slightly tamped. The voids must be filled with sand.

Formwork

Concrete porch formwork is the frame, the shape along which the porch will be poured. To do this, you will need to pick up strong boards and beams. They should not be deformed. You can fix the form with self-tapping screws or even ordinary nails.

The frame should be 30 cm higher than the porch itself. This is due to the deepening of the formwork into the ground. First, the risers are drawn, treads. They must have a right angle. After that, you need to draw the site and treads. Their slope should be 6 mm. The depth of the drain for water should be about 30 cm. Then the risers are indicated. The slope in this case should be 15º.

Stiffeners are attached to the sides of the mold. It is necessary to retreat from the wall of the house by 1 cm. Prepared formwork panels are mounted next to each other. The stakes must be driven to a depth of 25 cm. Spacers are installed between them and the formwork. The backfill of the base should be 10 cm. It is tamped. The size of the boards is adjusted in accordance with the dimensions of the risers. The boards are nailed to the formwork.

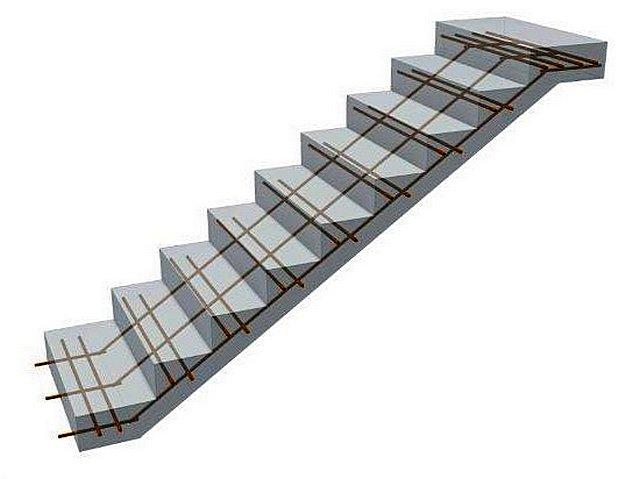

Reinforcement

If the owners of their own house are studying, how to make a semicircular porch from concrete or other configuration with large dimensions, it is necessary to pay attention to the reinforcement process. In this case, construction will be carried out using a more complex technology.

After the formation of the formwork, it is necessary to add reinforcement to the structure. It is also cut into the walls of the house. The distance between each metal element should be 10 cm. In height, the reinforcement should protrude 20 cm higher than the future foundation.

If the boards lead in the process of pouring, they will begin to deform, it is necessary to support them with special structures. Pouring is carried out starting from the first step. It is better that the concrete mixer is located in the immediate vicinity of the formwork. To avoid the appearance of voids, it is necessary to pour a sufficient amount of cement mixture into the mold.

Finishing

After the concrete structure has completely dried, you can start finishing work. When choosing a style, materials, be sure to take into account the general style of facade decoration. This will create a unified look.

Considering, how to tile a porch made of concrete, it is necessary to give preference to materials such as porcelain stoneware, clinker tiles or stone. In this case, the concrete surface will be additionally protected from mechanical damage. The appearance of the porch will be aesthetic.

After the installation of finishing materials, additional elements can be installed. It can be a railing, a visor. Also, if you have a large porch, you can equip a veranda here. The owners make the choice of additional finishing elements in accordance with their taste preferences.

Having considered how to create do-it-yourself concrete porch, every owner of a private house will be able to do the job well. The structure will be strong, reliable and durable.

In order to comfortably climb into the house, you need to make a porch. It can consist of one or two steps, or it can be at a decent height - it all depends on the basement of the house. In any case, the structure must be strong, therefore, before filling the porch, the site should be cleared of all unnecessary things - the old porch (if any), debris, grass, young growth of nearby trees. Construction technology begins with this.

Preparatory process

To build a comfortable porch in a private house, you should calculate the dimensions of the entire structure, prepare the site, and you can begin to build the foundation. The latter must be present, albeit small. And if the soil on which the house stands is clay, the pit under the foundation is pulled out deep enough (up to 70 cm) and strengthened with a mixture of sand and gravel. They are laid on the bottom, forming a kind of pillow, and only then they form the main foundation for the porch of a private house.

With dense soil, a hole 30-35 cm deep is enough. A porch made of concrete should be comfortable and safe - the site should be leveled, and only high-quality materials should be used. Since this structure will be constantly exposed to temperature changes and the influence of precipitation, it must also be especially durable, therefore the process of creating a porch is an exact adherence to technology and calculation.

Types of concrete porch

In addition to the size, you should also decide on the shape. It can be rectangular, square, round, oval. You can also attach a trapezoidal concrete porch to the house. It all depends on the taste of the owners and their imagination. But you need to make sure that the shape is in harmony with the overall appearance of the facade, otherwise it will look alien. A porch with a staircase can be located either on the side or on the front facade of the house (by the way, you can make several entrances, but then the process of building the porch will take a little longer).

Concrete is an excellent choice of material for creating a porch. It can be faced with stone, tiles, even wood and is stronger than other materials. It is not so difficult to create a monolithic concrete porch with your own hands if you follow the technology, but some nuances should be taken into account.

If the staircase is designed higher than 5 steps, you should leave holes for future railings even at the stage of concrete hardening. The same goes for the canopy - the supports for it are installed during the manufacture of the porch.

Design

- the width of the porch is made more than the door by 3-5 cm in each direction;

- and the height of the porch should not reach about 5 cm to the door frame;

- the pit for the foundation will be even slightly wider than the site - by 4-5 cm (this is an allowance for the thickness of the boards for the formwork);

- you also need to count very carefully. It should be at least 30 cm - designed for an average foot size. And the height of the steps is about 20 cm. With a larger one, it will be difficult for children and people in old age to climb into the house;

- the upper platform is convenient with a width of 80-100 cm;

- the staircase should be made inclined - 30-45 degrees is quite enough. So the ascent will be comfortable, and the water after precipitation will not linger;

- the width of the staircase itself can be equal to the size of the upper platform - 80-100 cm.

Calculation of materials for the porch

At this stage of construction, you should find quality materials for assembly, pouring, reinforcement, and so on.

You will need:

- Formwork boards.

- Reinforcement mesh.

- Crushed stone and sand.

- Cement brand M400, and better M500.

- Waterproofing materials.

- Water.

- Fittings (screws and corners).

You can also take ready-made concrete. But mixing it with your own hands (more precisely with a concrete mixer) and controlling the amount of components, you can achieve better quality. To obtain a good solution, you should mix 1 part of cement with 2 parts of sand, but crushed stone needs 3.5 parts of the cement norm. For 1 cubic meter of concrete, about 190 kg of M400 cement will be needed. Therefore, in order to calculate the amount of material, you need to understand how many cubes of ready-made concrete will be needed for pouring. And do not forget about the layer of rubble and sand at the depth of the foundation.

As for the reinforcement, it is believed that at least 2 rods should be consumed for each step. Most often, they take material with a cell size of 10x10 cm. It fits best into the formwork. For reinforcement calculations, it is worth measuring the quadrature of the lowest step and multiplying this figure by the number of steps.

The boards will be used to create the formwork. For each tier, that is, steps, you should take 3 boards about 2 cm thick.Do not take too dry material - it will crack under the pressure of concrete. The frame blocks for the porch should be fastened together with self-tapping screws, and the corners will help to install them evenly. The latter are needed only for a square or rectangular porch.

Design features

If the foundation is deep, you can scatter any non-combustible debris along the bottom - foam blocks, broken brick, even glass. But from above, all this is covered with an even layer of a mixture of sand and gravel.

The reinforcement should be cut into pieces of the required size in advance, it is not laid on the bottom, but on single-standing gas blocks or bricks - so it is all evenly covered with mortar and the concrete porch will be stronger.

Formwork on all sides can be additionally reinforced with pieces of timber or thick boards. The material for the formwork should be lubricated from the inside with a special compound - then it will be easier to remove it upon completion of construction work.

The concrete solution is sometimes supplemented with various additives, which give the required level of plasticity, make it frost and water resistant.

If a porch with steps is attached to an already erected house, it is necessary to leave a gap of about 10 cm between them. This is done so as not to damage the foundation of the house in case of possible deformation and create a so-called "expansion joint". A wooden shield can be laid in this space and filled with glass wool.

Design advantages

- The main advantage is that you can make a concrete porch device with your own hands. If you correctly calculate the amount of materials, follow the technology and do not save on quality, it will be durable and beautiful.

- Materials for the arrangement need the most common, which can be easily bought. They are not a deficit.

- Such a porch can be easily made original, since it can be revetted with stone, tiles, wood, and other materials. You can also use a mixed version.

- The end result is relatively inexpensive. You can choose the shape and size.

Cons of construction

Sometimes the porch quickly begins to collapse - crumbling, settling, loosening. This means that in the process of pouring its technology was violated. The porch of the house should be properly filled. As an option, a low-quality material came across, so you need to pay special attention to its quality.

Making the foundation

To make the porch foundation easier and faster to fill, in addition to materials, you need a small concrete mixer. The solution must be developed within about an hour and a half after its manufacture, then it will harden and crumble.

The reinforcement rods are cut into pieces of the required size and fastened together with a wire. So the concrete staircase of the porch turns out to be durable and does not disintegrate over time. The finished porch steps can be additionally secured with corners.

You need to dig a hole according to the size of the foundation with an allowance of 2 cm from each side. Next, crushed stone with a layer thickness of 7-10 cm is placed on the bottom (you can add any construction waste to save material). The same layer of sand is laid on top, carefully tamping it. Sometimes sheets of roofing material are also placed on the sand. The site should be flat. This is followed by gas blocks, reinforcement and finally concrete.

Site preparation

It is thoroughly cleaned of everything superfluous - garbage, bushes, grass. If we do the foundation with our own hands, we dig a hole 30 cm deep (if the soil is strong enough). In case of doubtful soil, the depth of the foundation should be deeper. Waterproofing and leveling of the site with sand and gravel are required. Pegs for the future formwork should be hammered along the perimeter of the site.

How to prepare concrete?

It is a mixture of cement, sand, and crushed stone in certain proportions. All this is poured into a concrete mixer and water is added. The consistency of the concrete should be doughy - not spilled, but not too dry. It should be easy to spread with a shovel and tamp. Sometimes concrete is supplemented with special additives to improve its technical properties.

Reinforcement principles

The consumption of reinforcement for a medium-sized porch is about 160 meters. Its thickness should be at least 10-12 centimeters. Reinforcement is the binding of reinforcement with wire in a specific configuration. You cannot save on its quality, like other materials. At the edges, pieces of reinforcement should be left under the future railings.

Installation of a concrete porch

After preparing all the components, as well as the area under the porch, you can begin to install it. To know exactly how to make a concrete porch with your own hands, you can watch a training video or work with experienced craftsmen.

The weather should be clear and moderately warm. You should go through all the stages one by one, without missing anything. 6-7 days after the end of the work, you can start finishing the porch.

We install the formwork

Boards for it are installed around the perimeter of the pit and secured with spacers. They should be wider than future steps due to the fact that part of it will go into the depth of the pit. The formwork for the porch is placed directly, fastened with self-tapping screws and, if necessary, corners. Stiffeners will also be needed - they strengthen the sidewalls.

If only dry boards are available, they should be moistened with water. The form of the formwork must exactly follow the outline. A trapezoidal concrete porch with your own hands is more difficult to create than a rectangular one, but it looks much more spectacular.

On concrete blocks or other support at least 5 cm high, reinforcement rods are laid, cut as needed. They are tied together with wire, preferably steel. Make sure that the fittings are not corroded.

Mortar creation

It requires a cement grade of at least 400. The solution is strong enough. Cement is mixed with sand and crushed stone in proportions of 1: 2: 3.5, respectively. Then water is added for the required viscosity of the solution. The mixture is thoroughly mixed in a concrete mixer and after that it is considered ready. It should have a uniform, fairly plastic consistency.

Before making a concrete porch with your own hands, you should think about and check everything. Directly to concreting, you need to start fully armed, because after it there is already little that can be fixed. After the pit has been dug, a layer of sand and gravel is filled in, reinforcement and formwork are installed, concrete mix can be poured.

It must be tamped in the process of pouring the steps, carefully spreading it with a shovel over the pit. It is imperative to get rid of air bubbles that appear in the solution. It is better to place the stirrer as close as possible to the pouring point. We fill the porch of concrete layer by layer: leave the first layer to harden a little, then the second, third, and so on according to the number of steps follow. At the end, we cover the finished structure with tarpaulin or roofing felt.

Concrete porch cladding

To finish the concrete porch, you should first clean it to smoothness, you can manually, you can use special devices. After that, it is painted, revetted with stone, tiles or wood. Everyone chooses the color, shape and type of surface of the facing material independently.

Clinker tiles look great, besides, they also do not slip. Many people opt for porcelain stoneware tiles. The veneering process is the same in both cases. The surface of the tiles is lubricated with special glue and firmly pressed against the desired section of the porch. When the cladding is finished, cruciform spacers are inserted into the seams to prevent the tile from slipping. Then they are removed, and the seams are rubbed with a special mixture. On this, the device of the concrete porch can be considered complete.

Final step-by-step instructions

So, in order to properly fill the porch with concrete, you need to do the following:

- Clear the place.

- Dig a pit.

- Install the formwork.

- Make waterproofing, fill the bottom with rubble and sand, you can build debris, compact.

- Make sure that the surface of the concrete floor is even, cover it with pieces of roofing material.

- Install gas blocks, lay the prepared fittings on them, tie the rods with wire.

- Repeat all steps starting from the formwork by the number of steps.

- Fill all the steps with concrete solution in stages.

- Cover the finished structure with roofing felt or tarpaulin.

- After a week, you can remove and clean the surface.

- Make the cladding to your liking.

The result is one of the most beautiful structures - a do-it-yourself porch that you can be proud of.

The concrete porch is one of the most durable. Thanks to the concrete, it is able to withstand heavy loads and is resistant to abrasion. You can do it yourself, the main thing is to make accurate calculations and draw the project correctly. Drawings will help you build the formwork faster and without errors. It is better to fill the porch on your own even at the stage of building a private house, since it also needs a foundation. If it is attached to a rebuilt building, then it will be necessary to equip the base and connect it with reinforcement to the foundation of the house.

When making calculations and making a drawing, the following factors must be taken into account:

- The height of the porch is the distance from the ground to the bottom line of the entrance door sill.

- The width is selected depending on the number of people in the house, and whether heavy and bulky things (furniture) will be carried through it. For one person, a width of 80 cm is enough, for two simultaneous passage you will need at least 100 cm.

- For a comfortable ascent and descent, it is recommended to build an unpaired number of steps. Width - 25 cm, height is selected from 12 to 20 cm, depending on their total number and the height of the porch. The width of the steps is chosen so that the leg fits freely. Then the porch will be safe. It also takes into account who plans to walk on it. If there are elderly people and children, then the height of the steps is made smaller so that the stairs are more comfortable.

- To prevent the front door from touching the surface of the extension, it must be poured 5 cm below the threshold.

- If the porch is high, then you should foresee the places for the installation of handrails or other fencing.

- The angle of inclination of the march is 27-45 °.

A pre-made plan with a diagram will save time and properly fill the porch for a private house, since everything will be painted step by step.

Step-by-step installation technology

Porch construction consists of the following stages:

- drawing up a drawing with a diagram;

- site and soil preparation;

- markup;

- assembly of formwork;

- concreting.

1. Site preparation.

Regardless of the chosen scheme and construction technology, you should first carefully prepare the place. The old porch is completely dismantled and debris removed. If it was brick, then the brick can be left nearby, as it will work as a filler. If shrubs or trees grew in this place, then everything is completely removed, and with roots. If this is not possible, then it is recommended to treat them with chemicals. Germinating plants can damage even concrete.

Before making a porch of concrete, you need to calculate the required volume of concrete solution. You will need water, sand, gravel and cement. The components are mixed in the following proportions - 1: 2.2: 3.7 (cement, sand, crushed stone). Cement grade - M500. Then the concrete strength will be 300 kg / cm2. They also prepare reinforcing bars, wire for their bundling, waterproofing material, boards, plywood (metal sheets), self-tapping screws, a shovel, a concrete mixer, a building level, a spatula and broken bricks.

2. How to build a foundation.

For the porch, a solid and stable foundation is made from concrete mortar. For this, a hole is dug with a depth of 30-70 cm. The depth depends on the degree of freezing of the soil and heaving. The foundation needs to be built 20-30 cm below the freezing level. The deeper the ground freezes in winter, the deeper the pit. The width is dug a few cm wider than the porch.

At the bottom of the pit, a substrate is needed; for this, sand and crushed stone are poured. First, sand is poured in a layer of about 10 cm and compacted. After that, 5 cm thick crushed stone is poured. Thanks to such a pillow, the foundation of the concrete porch will be protected from groundwater, and it will make the foundation stronger. The entire backfill should be at least 10 cm wider than the foundation of the future building.

The formwork is made so that it can withstand the load from the gravity of the concrete solution. The frame should completely repeat the shape of the future porch. For the assembly of the formwork, boards, plywood, metal sheets and bricks are used. Boards must be strong and not overdried, otherwise they will burst under the weight of concrete, width - 200 mm, thickness - 20 mm.

The sides are mounted, props and boards are installed for each step. There should be no gaps at the joints so that water does not flow out of the concrete solution. You can additionally strengthen the sides with reinforcement rods by sticking them into the ground. Reinforcing bars are laid inside the formwork with a step of 20 cm. Outside, the frame is poured about 10 cm with soil and compacted. After that, they start concreting.

4. Concrete pouring technology.

To increase the strength of the structure, not only reinforcing bars are used, but also broken stones and bricks. In addition, they help to reduce the consumption of concrete. Lay them under the reinforcement. It is best to use a concrete mixer for mixing, since a large amount of the mixture is needed, and its quality will be higher. As soon as the solution is ready, it is immediately poured, as it sets quickly.

Concrete is poured from the bottom step. Each stage is treated with a vibrating unit. It will help remove air and distribute the concrete evenly over the entire formwork area. Then it is rammed and smoothed with the rule. The evenness of the surface is checked by the building level. As soon as the concrete has frozen a little, they begin to pour the second stage and so on they rise higher. The formwork can be dismantled after about a week.

Fill the semicircular porch

Building a round or semicircular concrete porch with your own hands is somewhat more difficult than a square or rectangular one. The main difficulty is the arrangement of the formwork for concreting. First, you should carry out calculations and make drawings. The width of the area for a semicircular porch should be at least 50 cm wider than the front door. Then 2 people will be able to pass without colliding.

The midpoint from which all measurements are taken is the middle of the front door. It is from her that the lines of the location of the steps are applied in the drawing with a compass. The height of the steps for the porch is 16-18 cm. Above it is not recommended, since it will be uncomfortable and unsafe to climb such a staircase. The width of the treads should be from 26 to 30 cm, then it will be convenient to stand on them. It is this number that is added each time in the drawing when the next steps are outlined. It is better to make the angle of inclination of the porch less than 40 °.

To make a semicircular porch, you will need formwork, reinforcement and concrete mortar. It is better to knead the mixture in a concrete mixer. To build a semi-circular formwork, a flexible and durable material is needed. Plywood or galvanized sheet metal will do. To give the plywood a bend, it is soaked in water and bent to the desired angle. Then leave to dry. But since this process takes a long time, sheet metal is often used - it is flexible and durable.

The semicircular porch is large and heavy, so a solid base is required. A hole is dug, at the bottom of which sand and gravel are poured. After that, the fittings are laid. The porch foundation must be connected to the base of the house. Therefore, holes are drilled in the walls, and reinforcement rods from the porch frame are inserted into them. After that, concreting is carried out. A few days later, when the concrete has hardened enough, it is covered with waterproofing and proceeds to the construction of steps.

A curved formwork is mounted to each step. Supports are installed for strength. The main thing is that the entire structure can withstand the weight of the concrete solution. Reinforcement is placed in the formwork and concrete is poured. For greater density, it is processed with a vibrating machine, after which everything is leveled with a rule and left to harden.

After the concrete has fully gained strength, the finishing is started. First, the surface is sanded to remove all bumps and bumps.

The most suitable finishing material for a porch made of concrete is clinker tiles with a rough and anti-slip surface. It can withstand both heavy loads and temperature drops. Not afraid of both frost and heat. When its surface is wet, you can safely walk on it without fear of slipping. The tiles are laid on glue, which must be diluted only according to the manufacturer's instructions.

Concrete or paving slabs are also suitable. It has a low price, but over time it begins to crumble. Wood finishing material is most often used for finishing the porches of wooden houses.

To properly build the most concrete porch for a private house, you do not need to own construction skills. All you need to do is follow the pre-drawn plan and installation instructions.

After pouring concrete for 3 or 4 weeks, it must be sprayed (watered) with water to better gain strength. If it dries too quickly, then part of the cement will not have time to react with water, which will reduce the strength characteristics of the entire structure. In addition, due to the excessively rapid evaporation of water, the concrete shrinks unevenly. As a result, cracks appear on its surface. It is recommended to fill each new step only after the previous one has hardened - after about 4-5 days.

Basically, buildings are erected in different areas (lowlands, hills or plains). Sometimes it is necessary to attach a porch to the erected structure, but sometimes the extension of the porch is the idea of the developer.

Before installing the porch, you need to consider some of the nuances:

- The porch must be built thoroughly and adapted to negative weather conditions;

- Look harmoniously against the background of the house;

- The height of the climb and the size should be calculated clearly, otherwise the ascent will be difficult.

But it is not always possible to comply with these points; before installation, it is still worth considering some of the nuances.

Before planning the size, we recommend that you initially measure the height from the ground to the height - this will be the height of the porch. Taking this measurement, you will calculate the required number of steps. The optimal step height is a limit of 12-18 cm and the width of the upper step will be 15-20 cm wider than the front door.

For a comfortable exit, the upper step of the porch should be about 1 meter wide.

To make the risers and treads correctly, you need to draw them at an angle of 90 degrees.

The steps are approximately 30 cm wide; this must be done for safe ascent and descent.

Then we install the shield, prepared for fixing inside the box and fix it according to the size of the step height. We do it on all marked treads.

Before pouring the porch, it is necessary to make reinforcement so that cracks do not occur, for this you need to purchase a reinforcing rod with a diameter of 12 mm and make a strapping. For the correct implementation of the reinforcement, it is necessary to install the reinforcement on wooden blocks up to 5 cm thick and place them at the bottom of the box. This is necessary to fill the entire formwork with concrete, forming a layer of concrete under the rods and this will not damage the corrosion.

Select the size of the reinforcement so that, at the top point of the porch, it is 5 cm lower.

Be sure to open the box with boards and pegs after finishing the reinforcement. Don't forget to make the final screed using screws or nails.

Having calculated all the dimensions, you need to make a calculation and determine how much money you need for materials. You will need:

- Cement 400 or 500;

- Quarry sand, washed;

- Crushed stone of fraction 5-20mm;

- Armature;

- To assemble the formwork, you will need lumber.

After collecting all the data, you will establish the full cost of the porch, but without finishing. When attracting specialists to install the porch, its price will be slightly higher.

Preparing a mixture for making a porch

There are several options for pouring a porch... The first and expensive way is to use the services of special firms. The second and more profitable way is to make the porch yourself. Making a concrete porch yourself will certainly be a time consuming task, since you will mix all the dosages and ingredients yourself. You can use when mixing ingredients.

It is necessary to pour the steps from the very bottom, the process must be interrupted, since the concrete must harden.

To prepare a concrete mixture, you must: fill the container with sand in the required proportion, crushed stone, etc. We mix everything by hand or using a concrete mixer, while adding water. The ready-made solution at the exit should look like thick sour cream.

To prepare a concrete mixture, you must: fill the container with sand in the required proportion, crushed stone, etc. We mix everything by hand or using a concrete mixer, while adding water. The ready-made solution at the exit should look like thick sour cream.

When mixing ingredients to obtain the required grade of concrete, you should pay attention to the feature. On the bag with cement, the manufacturer indicates the amount of all components for obtaining concrete grades. Such indicators may differ, be careful and follow all recommendations. If you follow this method of calculation, you will receive a high-quality solution.

After pouring the concrete, you will need to wait until it hardens. After the solution has solidified, it must be removed and further work must be carried out. The finishing work will be the facing of the concrete porch with decorative materials. To do this, use porcelain stoneware tiles, artificial stone or natural stone. For facing the porch, it is better to use tiles with a rough surface.

The porch is the face of the house. It protects the home from the effects of bad weather, street noise, is an additional area that you can use for your own purposes, and provides a convenient approach to the house. This part of the mansion lends itself to great stress. Therefore, during its construction, you should know the sequence of all the work, how to fill the porch with your own hands reliably and correctly.

In this article, we will take a closer look at the technology of constructing a porch made of concrete with our own hands, from the design and installation stage to finishing.

The role of a concrete porch

Often, when building houses on a high basement, there is a problem with the construction of a porch that would correspond to the house. Since the veranda is located near the central entrance to the house, then the choice of its model should be approached responsibly. The construction should correspond to the design of the house, be its harmonious continuation.

Remember: an improperly poured concrete porch can ruin a good impression of the exterior of a mansion.An important role is played by the choice of material for making the veranda. If the house is built of brick or concrete, then these materials should be used for the construction of the extension.

Small concrete porch with a plank floor in the country

Concrete porch erection technology

Let's take a look at how to build a concrete porch yourself. Since this is a serious extension to a residential building, you first need to familiarize yourself with the technological aspects of its construction, the rules for preparing the foundation.

Consider: work on the construction of a veranda requires special attention and control at all stages.Drafting a project

As with any structure, you should first develop an extension project. The veranda can be erected together with the house, or attached to an already finished structure.

Stylish porch made of concrete, photo

The veranda consists of a platform and steps. Building codes and rules for constructing a concrete porch will help determine their dimensions. The height of the extension should correspond to the distance from the ground to the bottom of the threshold. To determine the width of the staircase, you should know that for one person to pass through, an opening 0.8 m wide is required, and in order for two people to separate on the staircase, it should be no more than 1 m.

To prevent precipitation from accumulating on the site, it is built at an angle of 26-45 degrees. For its safe use, the site must have a depth of at least 1 m.

Depending on the height, the extension may have steps. Their number should be unpaired, so it will be more convenient to climb them. For comfortable use of the stairs, a step width of 25 cm will be sufficient, with a height of 12-20 cm.

Attention: if a concrete porch for a house, the construction technology of which is described below, is attached to the house, then it should be 50 mm below the threshold of the door so as not to interfere with its opening.Having calculated all the necessary dimensions, you should draw up a sketch - a project of a porch of a private house made of concrete. It will be easier to carry out further work with it.

Monolithic porch - building blueprint

Materials (edit)

Before making a concrete porch, you should prepare the necessary materials:

- boards for wooden formwork (thick, to form the frame);

- concrete, a mixture of cement, crushed stone and sand;

- reinforcement 12 mm in diameter, as well as wire for knitting it;

- finishing material (stone, tile).

Tools

Work order

The construction of a concrete porch takes place in several stages:

- clearing and preparation of the site for construction;

- calculation of the size of the structure;

- manufacturing and installation of formwork;

- pouring concrete.

Preparatory work - site clearance

First you need to clear the area for the extension. A pit should be dug under the foundation (a hole about 30 cm deep, which in width will exceed the dimensions of the foundation by 2.5 cm).

Attention: a shallow foundation is being built under the concrete porch. Its depth should be 20-30 cm below the level of soil freezing.Then, at its bottom, a substrate of sand and crushed stone is made. A layer of sand (about 10 cm) is tamped first, followed by a layer of rubble (5 centimeters).

The base of the foundation is a sand-crushed stone pillow

On a note: the substrate is needed to protect the foundation from groundwater, as well as to strengthen its foundation. It should extend beyond the perimeter of the foundation by 10 cm.If the foundation is located in the zone of groundwater, they should be diverted.

Installation of formwork under the foundation

After the formation of the pillow, you can proceed directly to the manufacture of the concrete porch itself. Like any structure, it needs a frame - formwork. It must be a stable base that can support the weight of the concrete to be poured. It is a box-shaped structure consisting of edged boards, OSB-boards, plywood and fully matches the appearance of the future concrete porch.

How to make porch formwork? For its construction, they take strong boards, at least 2 cm thick and about 20 cm wide.

Attention: do not take boards that are too dry - they can crack.How to set up the formwork? In height, it should be 30 cm higher than the height of the concrete porch, since its lower part enters the ground. Then the side formwork brushes, the location of the risers and treads are outlined. To form their frame, boards of the required width are used. The details of the formwork are connected to each other and fixed with spacers. This ensures the strength of the entire structure.

Exposing the formwork

The sides of the formwork should be reinforced with stiffeners. It is possible to additionally perform strapping with reinforcement - reinforcement. To do this, lay the reinforcement with a step of 20 cm according to a previously drawn up sketch.

Spacers are made between the stiffeners and the formwork. Then all this is covered with a 10 cm layer of soil and well compacted. When the formwork for the porch made of concrete is ready, we fill it with a concrete mixture (preferably grade M200 (B15) with a frost resistance factor of F150, which will ensure the reliability of the structure). It can be prepared by hand or mixed in a concrete mixer.

How to properly fill the porch of the house? Pouring is performed starting from the bottom step. The loaf is leveled with a shovel. After filling each step, it is covered with a wooden shield. This will protect the structure from drying out and waterlogging.

An example of how you can cement a porch

Advice: porch concreting is best done by adjusting the concrete mixer directly to the place of work.If in the future a canopy is installed above the concrete porch, then it is better to install the support pillars for it at the stage of formwork installation. To securely fix the base for the visor, it is poured with concrete.

Pouring concrete for the support post of the canopy

The concrete surface, which is subject to decorative finishing, must dry completely in the formwork for a week. In the warm season, in order to avoid drying out of the concrete, it is periodically moistened with water. After its complete drying, the formwork is removed. To do this, the boards are tapped with a hammer so that they fall behind the concrete base.

The formwork should be removed gradually and carefully so as not to damage the concrete base.

When the formwork is removed, the porch surface must be sanded. Rough roughness can be removed with a stiff steel brush. It can also be done using an electric tool with a special grinding attachment.

After sanding, the surface of the concrete porch will become smooth and even

Finishing work

After leveling the surface of the concrete porch, it is ready for finishing. For these purposes, stone and tile cladding is used. To give the veranda a more presentable look, it can also be painted with weather-resistant paint.

Painting a concrete porch with your own hands, photo

We examined the main stages of building a concrete porch with our own hands. How to avoid typical mistakes during its construction, will demonstrate the video:

Varieties of concrete winglets

The shape of a concrete porch can be varied: rectangular, square, trapezoidal, semicircular. An oval extension is more difficult to complete.

Before filling the porch with a semicircle, similar calculations are performed as in the construction of a conventional structure, only taking into account the fact that the steps will be rounded (the center of the circle is determined).

Beautiful round concrete porch

Outcome

The porch is one of the most important and beautiful elements of a residential building. It not only decorates the building, but also protects it, makes it more convenient to use. Armed with our tips for building it, you can do all the work yourself.