Such furnaces are widespread among the peoples of Central Asia. From other designs differ in the form: externally, they resemble a jug with a wide bottom and smooth walls that are tumped up.

Unusual geometry and special properties of the material allow you to accumulate heat in the walls of the furnace, which is used to prepare various dishes. Most often, meat dishes are fried in it (kebabs), bake various types of cakes, prepare pilaf. The walls have the same temperature over the entire height, therefore such troubles, as an unevenly bucked dish, does not happen.

The original oven made through ancient technologies is made only from clay dried in the sun and burned on a fire from saksaul wood. It is easily built in Central Asia, but it is impossible to create in our latitudes. The reason is the lack of conditions for dehydration of the material.

To the walls of the furnace acquired the necessary qualities, a very low humidity is required, a certain light spectrum, a high firing point. Under such conditions there are no internal stresses and cracks. Fully remove moisture from clay in our conditions it is impossible, it remains in large numbers even in a dry wall. Water begins to evaporate intensively during the firing, which leads to the appearance of cracks on the surface, worsening the heat-block properties of the structure.

Therefore, in the distance from Central Asia, modified tandars are built, for example, from bricks that are covered from the inside with a clay solution. They are much thicker than traditional clay and require more fuel to warm up, but in average latitudes there are no problems with firewood. Of all types of brick tands, the best are considered to be constructed from chammed blocks, which, after thermal processing, acquire the properties of ceramics.

Tandoor from bricks are used as follows:

- Inside the furnace, lay the fire and maintain it until the walls are warm up to high temperature. All this time it accumulates heat.

- After burning firewood, wait when the walls are coated to a temperature of 250 degrees.

- Put the products inside and cover the neck with a lid. Clay bricks hold high temperatures long enough and provide preparation of several dishes bookmarks.

How to make a tandoor of bricks

To build a furnace with heat-monitoring qualities, perform work in a specific sequence and choose the right building material. Consider more each stage.

Choosing materials

For the construction of a tandoor of bricks, they will need special refractory chammed materials - brick and clay.

Chammed blocks are made of clay chamotte mixture. There are several types of building materials that differ in density and fire resistance. For our case, samples are suitable with marking Sha, SB. Bricks are produced three sizes: 230: 113: 65 mm, 250: 123: 65 mm and 300: 150: 65 mm. Due to the large dimensions of the blocks in the walls there are fewer gaps, which makes it easy to get a smooth surface.

Chamotte blocks are more expensive than ordinary silicate, so not to overpay, make a drawing of a tandora from a brick, according to which you can define their exact number.

For the oven, choose a material of good quality, paying attention to some points. Suitable samples have an attractive appearance of sandy color and grain base. When tapping, they publish a metal sound, and after impact it is broken into large pieces. Related bricks are scattered on the crumbs, and the sound after tapping on them is deaf, it is impossible to build furnaces from such blocks - they do not retain heat, they have a low strength, so the design can simply fall apart.

Before buying, make sure that the material was stored in a dry place, because He absorbs moisture well, after which she loses 75 percent of its qualities. When used on the street, take measures to protect the design from atmospheric precipitation.

Chamotte bricks withstand a large temperature, so with them can not be putting silicate or ceramic samples. Over time, the wall of the combined material will simply collapse.

For the same reason, do not use the usual sandy cement-cement elements to fasten the elements. For such purposes, a special heat-resistant solution is a marvel. It is made of crowded chamotte bricks and clays. The mixture has increased strength and grasp, which will allow its thickness with no more than 1 mm.

Masonry solution can be prepared independently of chammed clay, which is sold in a dry form in building stores. It comes on sale in bags of 20 kg. One package is enough for masonry 20-30 bricks. To build 1 m 3 walls you will need 5 bags of material. When buying, make sure that the shelf life of the powder has not yet expired, and he was stored in a dry place. Wet material loses its qualities.

The mixture also add other substances that change its properties. For example, special agents that are combined with shamot - cement, salt or liquid glass are added to reduce time on setting. Quartz sand is injected into the solution if it is too liquid.

Preparation of masonry and plastering solution

For self-preparation, you will need chammed clay, salt and quartz sand in a 4: 1: 1 proportion. The usual mixture on the base of clay and sand is quickly covered with cracks and poorly connected with bricks. The prepared composition is very plastic and quickly grasped, during operation it does not peel.

The solution is mixed as follows:

- The bag of chamotte powder and all the components pour into deep containers and fill with water so that it covers the substance.

- Leave the solution for 2-3 days (specify the instructions attached to the substance), mixing periodically.

- At the end of the deadline, all times, all mix and check the viscosity of the contents of the container. It must remind a thick sour cream. If the mixture is too liquid, add the sand, if thick is water.

- To reduce the term of frozen, add cement to it, no more than 2 kg per 20 kg of powder. Instead of cement, you can make a conventional salt at the rate of 100-150 g per bucket of solution or liquid glass in an amount of 1-3 percent of the mixture volume.

- The amount of solution must be calculated in advance to spend it before harmony.

Construction of the founding of Tandara

The furnace is based on a solid base, which eliminates the appearance of cracks on the walls during seasonal priming of the soil. Therefore, before build a tandoor from a brick, study its composition. The most favorable is the rocky and sandy soil. For safety reasons, the design should be located at least 3 m from buildings and plants.

On bunched and clay soils for a tandoo furnace, a reinforced foundation is needed, for example, a column. In other cases, it is possible to do with a slight base in the form of a monolithic plate.

To make a foundation, perform operations in such a sequence:

- Draw on Earth a square 120x120 cm, it will fit the furnace of standard sizes. Draw a hole in a depth of 10 cm in the perimeter, and on the perimeter, select the soil to a depth of 15 cm. In the corners of the cutlery, with a depth of 70 cm, with a diameter of 12-15 cm. Push the layer of 10-15 cm in the removal of sand.

- Install the reinforcement into the holes, cooked into the quadrilateral, and fill it with concrete, while it should rise above the bottom for 5 cm. Concrete speech can be provided with formwork. The solution is prepared from sand, cement and gravel, which are taken in the proportion of 3: 1: 1. Gravel fractions should not exceed 1 cm. Cement Choose not lower than PC-400. After the concrete is frozen, remove the formwork and pumped the bottom of the sand flush with the concrete belt around the perimeter of the pit. The raw mass conclusted and fill with water.

- Prepare the formwork for the monolithic plate, providing its speech over the soil by 10-15 cm.

- Cook the reinforcing grid with 15-20 cm cells. Put it into the pit. It is made of rods with a diameter of 10-12 mm. Rods can not be welded, but to connect in places of intersection of an annealed wire. Ideally, if it turns out to be at a depth of 5 cm from the surface of the stove.

- Fill the pit with concrete and check the horizontal surface, wait 2-3 weeks to solve the solution.

- The basis of the product is a circle, so on the prepared platform, apply a circle with a diameter of 75 cm, this is the most popular size of the tandoor of the brick.

- Fill the makuto inner part of the circumference with blocks, suturing unnecessary with a barrage with a diamond disk or a special disk for cutting stones. Number each brick and bring their location on paper.

- Free the platform from the material, apply a layer of solution to the entire surface and put the blocks according to the composed sketch.

Construction of the walls of Tandara

So that all the furnace elements corresponded to the brick tandyard designed in advance, we recommend using a special template in the form of a frame. Without it, it is difficult to lay the material around the circumference with the same radius.

The dimensions of the device depend on the height and diameter of the furnace. As a rule, the height of the tandora is equal to its diameter, and the neck is 1/3 of this size. One side of the template, which is installed in the center of the base, make a hest with a height of 1 m. To it perpendicularly fasten 3 strips, with a step of 25 cm: at the bottom - 30 cm long, in the middle - 25 cm, at the top - 20 cm. When rotating it will show Deviation of the wall from the specified form at this level.

It will also be needed with gloss, according to which you can lay bricks. For this purpose, the lamels will fit the bed under the mattress.

Build the wall in such a sequence:

- In order for the design to be stable and had an attractive view, draw a brick tandoor coach.

- Apply outside the circumference with a solution layer with a width equal to the smaller side of the brick. Place the blocks in a circle on it by setting them on the edge, the end. Internal edge set out unzymatically. Seams close up with a solution. After laying out the first row, turn it with the wire, and the ends hide between the bricks.

- In the second row, leave a small window through which the air will come inside the design. It can be closed by an iron door. Also in the opening is allowed to establish a chimney pipe.

- When the height is achieved 100-120, start forming the neck, the height of which is 25-30 cm. For this, all bricks of higher rows slightly tightened inside. Often, the hole do not on top, and on the side, but in the classic version, the tab is performed from above.

- After reaching the required form, leave the structure for 2 days to solve the solution. If the furnace is planned to prepare cakes, cover the inside of the masonry of the tandoor of the brick mixture from chamotte clay. The layer must be quite thick - not less than 10 mm. For the preparation of kebabs or pilas, the wall inside can be left without finishing.

- Outside, cover the furnace with a solution, and then separate the stone to give the design of aesthetic appearance. Wait 2 days so that the clay is dried.

Often, inside the furnace fasten the frenzy with hooks, on which the meat can hang. In the Uzbek version provide grille. It can be on it, besides meat, cook fish and vegetables. All products will be uniformly rooted from all sides.

Rules of Operation Tandara

When using the furnace, it is necessary to adhere to some rules that will prolong its service life and facilitate operation:

- Temperature in Tandara raise gradually. In the winter, they first burn a small amount of chips, and then add the main fuel. In summer, such a procedure can be skipped.

- Fly fuel is allowed to the height of no more than 2/3 of the design. It is not worth noting anymore, the heat will simply disappear through the top.

- The type of fuel does not matter. You can use firewood, coal, trigger, no temperature restrictions.

- If the fat fell on the walls, do not remove it. It will simply burn with the next use.

- Asha remove as a scroll and a poker through the hole above. This is the only disadvantage of the device due to the obvious inconvenience of the operation.

In some structures, it is planned to pondered from where the ash can be removed through the door, but this option complicates the device.

How to make a tandoor from bricks - Watch the video:

For the manufacture of such a furnace, the experience of construction works is not needed, all operations are quite simple. The main condition for obtaining a good result is the performance of the technological process in a given sequence. Important material also has the material and observance of the timing between the stages.

Cooking over the heat of hot coal has long been entered into the tradition of dacnis. This uses a very different brazier: mangals, barbecue grills. In addition to them, in the courtyards of connoisseurs of oriental cuisine, you can meet more unusual for our eyes and understanding the device - a furnace-tandyard. The peoples of Asia are preparing in it almost all national dishes, ranging from lush pellets and ending with a juicy kebab or chicken. The taste of food from an exotic furnace is unforgettable! You are easy to make sure that if you decide to make a tandoor with your own hands.

Tandar - Flaking Farming for cooking Eastern cuisine: kebabs, sams, tandar-nan pellek

Tandar is a hollow clay vessel, tapering up. At the top there is a hole (like in any vessel), through which fuel and prepared dishes are placed in the oven. At the bottom, it is satisfied with the damper to provide thrust. To enhance the thermal insulation characteristics of the furnace, the clay base is tinted with bricks. Between brick and clay walls, accumulating materials are covered with sand, salt, clay.

Tandora design with clay base and brick casing

In the process of combustion of fuel, the tandoor walls are accumulated heat and are spinning to temperatures 250-400 ° C. The clay has excellent thermal insulation properties, so the operating temperature in the stove is preserved for 3-4 hours! And all this time inside the ceramic vessel you can furnace, fry and cook. Preparation of food occurs due to powerful heat transfer, but not outward, but inside the tandyard. Due to the smooth high temperature inside the furnace, the meat in it is relocated evenly, the pilaf is obtained crumbly, and the bread is unusually fragrant.

Method of making clay tandora

In accordance with the classical ancient technology, the real masters tandyrer are not built, but are pushed. From kaolin clay, mainly Ahangaran origin, which is famous for its thermal insulation qualities. In order for the clay oven to be cracked when it is filled with the "latter" with high temperatures, to kaolina mix wool camel or sheep. Make a classic tandoor is quite difficult, due to the fact that the exact composition of the kaolin mixture by Asian masters is not disclosed. We'll have to do everything on the eye, experimenting and correcting your own errors.

Classic tandoor is made of environmentally friendly refractory clay with adding sheep wool

The averaged technology looks like this:

- Kaolin is mixed with wool (sliced \u200b\u200bfibers of 10-15 mm). The mixture should turn out to be viscous, similar to thick sour cream.

- The clay composition is left for a week so that he will sleep and reached the condition. All this time, the mixture is stirred for uniform drying. If water accumulates on top of the mixture, it is desirable to drain it immediately, and not interfere in the composition. Remember that the smaller the water in the clay, the less chance that Tandar will go cracks during drying and firing. At the end of the preparation date, the composition should be similar to dense plasticine, from which you can sculpt anything.

- Of the clay "plasticine", oblongable flat sheets are pushed with a minimum thickness of 5 cm. Of these, moving in a circle, form a tandoor. Classic dimensions: height - 1-1.5 m, diameter to narrowing - 1 m, the diameter of the neck is 0.5-0.6 m. At the bottom of the side, the air impending hole is left.

- Leave the finished tandan to dry in the shade of about 1 month.

- Plide the clay walls with chamoten bricks, using kaolin clay or a special furnace composition of clay, quartz sand and plasticizers as a solution. Between the clay and brick walls gradually fall asleep sand, salt or clay, trambus each laid layer.

- From the inside is destructive a clay chunk with cotton oil.

- Begin the firing of Tandara, arguing clay to the state of ceramics. The temperature is raised slowly, gradually. The firing can last up to 24 hours. Such slowness is associated with the appearance of cracks with a sharp warming of crude clay.

Interesting facts about the classic tandoore and technology of its manufacture can be found by looking at the video story:

Simplified classic tandoor with barrel at the heart

Homemade craftsmen, having tried their strength in the manufacture of Tandara at the cottage with their own hands, often note that it is quite difficult to form it without experience. It turns out space crooked, and when drying cracks. Therefore, a simpler "recipe" of the manufacture of an Asian oven, based on the formation of clay walls around a wooden barrel, was revealed.

Using a wooden barrel as a template greatly simplifies the manufacture of tandoore

Consumables:

- kaolin;

- chammed sand - fraction up to 0.5 mm;

- sheep (camel) wool;

- wooden barrel with metal hoops;

- vegetable oil.

The order of work is such. The barrel is filled with water, leave one day to impregnate wood and its swelling. Clay is mixed with sand and wool in proportion 1: 2: 0.05, leave for several days to dry out and set of plasticity. Then drain the water from the bar, wait for its drying. A layer of vegetable oil is applied to the inner surface of the barrels, leave for impregnation overnight. The finished clay solution is applied to the inner walls of the barrels with a layer of 4-5 cm. Wet hands grow surface, trying to achieve smooth walls. Gradually, the clay layer increases to obtain a narrowed throat of Tandara. In the lower part, there is a small hole for imaging air during the furnace.

Drain the tandoor should be in a dry, ventilated place in the shade. Usually it lasts 3 weeks-month. Gradually, wooden rivets of the barrel will begin to lag behind the clay sides of Tandara. When the drying process ends, the metal hoops remove and exempt the tandoor from the barrel.

Set the tandoor on a thick sandy pillow and conduct the firing, that is, the first protostka. For this, weak fire are bred inside the furnace, which is supported by new fuel portions about 6 hours. After that, the tandoor is covered with a lid and burn the fire is stronger, gradually bringing it to the maximum. Cooling the furnace should slowly.

We can say that Tandan is ready. However, to enhance thermal insulation, it is desirable to further insulate it: to build around brick walls with clay, sandy, felt or cotton layer.

Modern version of Tandara - from brick

As mentioned earlier, the classic tandoor, made entirely of clay at home, often cracks during drying and firing. It is necessary to be a lucky one to make the first time not to be mistaken in the calculations of the clay composition and temperature mode of the processing process. Make a clay tandoor is not as simple as it seems! For many masters, he simply falls apart in the first week of drying. In order not to risk once again, we suggest you to make a tandoor with your own refractory bricks - this option guarantees an excellent result, despite the fact that in appearance it will differ from the classic Asian oven.

For brick tandyard, it will be necessary:

- chamotte (refractory, chunk) brick;

- chimney - for masonry;

- chammed clay (kaolin);

- sand, reinforcement grid, concrete - for foundation;

- wooden pattern template.

Now we denote the stages of manufacture.

Stage # 1 - Foundation

On a flat platform, they dig a round pit, the diameter of which is a little more base of the future tandyard. At the bottom of the pit it is suitable for a sandy pillow with a thickness of about 10 cm.

Kotlovan for the foundation is digging to a depth of at least 40-50 cm

On top of the cushion lay down a metal grid woven from thick wire or fittings.

The reinforcement grid enhances the strength and reliability of the concrete slab

A concrete is poured into the pit, aligning it with a metal rule and controlling the horizontal building level. Subsequent works are performed at least a week later when concrete grabbing and gains initial strength.

Concrete foundation should be perfectly smooth and smooth

Stage # 2 - formation of brick walls

Laying the brick is carried out in a circle of the designated diameter. Usually it is 1 m. Bricks put on the end, and, adhering to a wooden frame-frame, form a circle. Laying is performed on a solution from a furnace (refractory) mixture. In its composition: chammed clay, quartz sand, plasticizers. Due to the carefully selected components, the solution does not crack during the firing, plastic, quickly grasps.

Using a wooden frame-template allows you to form a brick circle with a predetermined diameter

At the bottom of the brick tandyard, leave the hole for pushed. Its role can perform a smoke tube or a common window with a metal flap.

For a tandora, a height of 1-1.2 m will be enough to fit bricks in 4 rows. The last row will form a narrowing neck, so bricks at this stage are laid with a slight inclination inside.

Confused from the chimney pipe to be satisfied with the bottom of the wall of Tandara

Tandar with her hands from brick after manufacture should dry completely, only after that you can perform a firing

Stage # 3 - coating clay and stone trim

With the outer and inside, the tandoir is failed with a thick layer of chammed clay, 5 cm thick. Also, at this stage, a tandora was finished with natural stone - for a presentable type of product.

Tandar, lined with natural stone, can be an interesting element of the landscape design of the site

Stage # 4 - First Firing Products

It is done in the same way as in the case of a classic clay tandoome. They burn inside the fire, gradually warm the walls of the stove to high temperatures (up to 400 ° C), then they give slowly cool.

About how to make tandoor with your hands from brick, clearly demonstrated in the following video:

Furnace Tandara - Multifunctional device. And most importantly, not only experts can build it. Independent construction of the furnace is also possible.

What is the tandar

- Tandar is a big clay boiler, an inverted neck down, in the bottom of which a small hole is equipped.

- The clay part of the oven from the outside is covered with brick, and the space between the brick and the edge of the vessel is filled with clay, sand or salt. They contribute to the deduction of heat in.

- This design is such that in its lower part there must be a hole for pond.

How it works

For such a furnace, there is a small amount of fuel - wood or branches. In Asia, Saksaul is used most often for the extract. It is placed on the bottom, ignite and give root to coal. After the firewood burned, you can start baking bread or cooking.

During the extracts, everything is absorbed by the walls - and the clay boiler, and a peculiar layer, and a brick wall. Warring, the oven begins to give heat. It provides a long-term uniform temperature that contributes to excellent cooking dishes, both baked and tomber.

What is needed for construction

In order to make such a furnace, you will need:

- bricks - refractory and facing;

- sand;

- clay;

- cement;

- grate.

This tandoor makes a little of other materials, but in modern conditions the listed components are best suited for this.

Build technology

Initially, the type of tandyard is ordinary (ground) or earthen, horizontal or vertical. The most common ovens are vertical.

Land or earth-type assembly technology is different.

Ground construction is built in this way:

Construction of vertical tandyard Photo:

Video

Another option for the construction of Tandara is presented on the video:

Earthy tandoor is assembled as follows:

- It is necessary to prepare the cutting under the oven, based on the fact that the height will be 1.2 m plus the foundation. The bottom, or the foundation, is laid out of the brick in one layer. Asbestos-cement pipe is supplied to the prepared foundation, which is peculiar subdomains. The edge of the pipe should be located among the bricks of the first row.

- Top masonry need to smell clay. Tandan is assembled in a similar way, except for the external cladding with bricks. The soil will act here in the role of facing.

The walls of the oven itself must be put out of refractory brick, with a shift of bricks inward for the formation of the upper cone-shaped dome. Outside, the masonry must be crucified, and after its drying, the space between the soil and walls should be thoroughly covered with clay and sand. The furnace must also harden with fire.

Construction of an earthly tandyard photo:

Stay at the cottage is unity with nature. I want to cook food on fire, sit by the fire, listening to twilight rustles. For cooking on fire, brands are most often used or barbecue, and we suggest you make a tandoor with your own hands. What it is? This is an eastern oven-brazier, which allows you to prepare a lot of exquisite dishes, which otherwise prepare is simply impossible. Samsa, Lavash, Eastern meat - all this can be done in Tandara. Moreover, the meat is very tasty, because it hangs in a horizontal position, as a result, the fat does not eat on the coal, and flows on pieces of meat, making it juicy and soft.

Skewers in Tandara is much tastier due to vertically located sheds. On the grill, the meat should be watered by marinade or spray with water, and here it turns out gentle and juicy

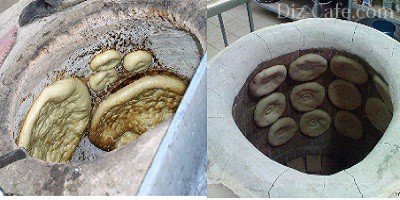

Very interesting, in the opinion of the European, in Tandara, cakes and samsa are preparing - they are attached directly to the stove walls and bakes in this way.

Oriental pellets and sams in tandyra are baked, stripped to the walls of the furnace. This bread has a special taste. Having done a tandoor, you can furnace samsu, pita and delicious cakes

The traditional form of such a furnace is round. It can be located above the ground, and underground. Today, the tandoor from the brick is building many dackets, it is not so difficult to make it, but the eastern cuisine will deliver a lot of pleasure and family members, and guests.

In the east, Tandara can be located in the house, it is installed at the center of the room to warm the air in the room during the cold season.

A small tandoor can be made on a platform with wheels, you can carry it into any place garden.

Tandar can also be bought if the means allow. Here is such a ready tandoor with a platform on wheels can be installed anywhere in the garden or in the house

If the furnace is stationary, it is better to place it on the stony or sandy soil, away from buildings and green plantings. The land under the tandon should be dry.

How to make a tandoor? For construction, you can use stone blocks, ceramic clay brick or white refractory brick. Initially, the base is laid out. The tandoor of the brick is rather heavy, so the base should be strong. The base of the furnace is similar to the foundation in which the opening is made, where the fuel is laid.

You can build a tandoor directly on Earth, in this case, under the base, you need to dig a hole in the form of a circle, with a diameter of 120-130 cm. At the bottom, we fall asleep sand (layer 15-20 cm), and begin to lay out the brick well.

The base under tandoor - the sand pillow is done at the bottom of the base, the vehicle site is also falling asleep with sand. At the bottom it is convenient to arrange the grille under the corners

As a solution for masonry, you can use the finished stove mixture. It consists of plasticizer, red clay and quartz sand. The masonry can be both horizontal and vertical, in the first case the furnace will keep the heat longer, the second is more economical - the bricks will need much less.

Tandoor laid out vertical masonry with gas removal tube. Material for the manufacture of such a furnace is consumed less

The brick tandoor laid out by horizontal masonry - the wall thickness is greater, so it holds the heat inside longer. In any tandoore, the hole should be located for the flue gases

To visually see the dimensions of the future furnace, at first it is possible to make a spoke - masonry without a solution. We work with a brick with a grinder with a cutting diamond circle on ceramics.

The order is made for a visual presentation, how your tando will look like. After such a calculation, you can proceed to work with a solution. Tandar can be built on Earth or on a brick basis

Making a round masonry is not easy, you will help you the drawing of a genuine value made with the help of the transport and circulation, the ability to handle the grinder has the latter.

The scheme clearly demonstrates the device of a brick tandoor. Features of the furnace manufacture may differ, but the basic principle of the structure is always one - the base with the fuel hole and the body, which is clistered up

Bricks pattern - base for the formation of a circle. Do not spare the solution when laying, and use the level to check the horizontal position.

For the manufacture of tandoore, the eastern wizards used a similar pattern. Laying out bricks according to the template, the furnace will gradually acquire a narrowing form

Tandar is too touched - it is done so that the heat is held inside. In order to achieve such an effect, the bottom layer of the brick must be cut off, when laying the form will resemble the arch. After the laying is ready, it is necessary to clean the inner space of the furnace from the traces of the solution. Dry clay use to fill the seams from the outside. The inner surface is also cooked by the clay, which is mixed with fine grass.

When the furnace is driving, it is molded first with paper, and then the firing temperature rises. This is the easiest way to make a tandoor, and if you want to reflect it, the design can be deceived by clay. In the east, the furnace is decorated with mosaic tiles, sandstone, ceramics.

The video demonstrates how to make a brick tandoor, using the template:

Option # 2 - Tandora of wooden barrel

Of course, the brick tandoor is the most durable and practical, but if you wish, you can use in other ways that we will tell now. Here you need skill work with clay.

It is necessary to find a small barrel with poorly impressed hoops. The barrel from the inside is impregnated with refined sunflower oil, leave it overnight for impregnation.

Then we prepare the solution - sheep wool for reinforcement (length up to 15 cm), chammed clay, chamoite sand. The ratio, respectively - 0.05 - 1 - 2. Make a thick solution and we cut the furnace housing along the inner surface of the barrel (thickness - 20-30 cm). The solution is loaded and dried a week with incandescent bulbs. Then the hoops can be removed, and the barrel to disassemble. After that, the product is subjected to secondary burning.

Option # 3 - Brazier using plastic barrel

You will need a plastic classical barrel. Fill it with water, after filling, the barrel is slightly increasing in size, its outer surface is deceived by chammed solution, it will be touched, loaded until the contour of the furnace is formed. The product also successes a week, and then water must be drained. The barrel will become less and it will be possible to extract from a new tandoor.

On top of the furnace can also be made to the preparation of pillies and other dishes, but for this you need to adjust the crown for the volume of the cauldron, the crown is cooked by clay.

The construction of the furnace is the main point, but you will also need to make metal mounts for Shapmur. For example, these are three brackets with a metal hoop in the center. The easiest option is to use a durable rod, putting it along the crown, and attach the shampoo to it

If you have a skill of pottery art, the tandoor can also be made with an ornament on the plot. For example, create such a "house" for the preparation of delicious oriental dishes

We reviewed several simple methods of manufacturing Tandara at the cottage. These are the easiest answers to the question, how can you make a tandan with your own hands. More complex options are offered to manufacture a structure resembling a Russian oven, but it is a bulky structure and build it quite troublesome and hard, and a simple tandoor is quite suitable for cottages and dishes in it are very tasty, try, and you will see for yourself.

The one who loves to relax in the country can not do not love kebabs. What can be delicious meat grilled on coals, watered with fragrant sauce, and acknowledged by a pinch of oriental spices? The answer is simple - only meat baked in a tandoor of a brick.

A brick tandoor is a Turkish oven that allows you to prepare just incredible kebabs. The secret is that the meat is baked as uniform as possible. Such effect is possible to achieve a balanced heat due to the balanced spread.

You, probably, more than once had to face the situation when in a kebab, some pieces were delivered to a black crust, and others were practically raw. The fact is that the coals under the skewers are unevenly and also have different temperatures. The result of such baking is obvious.

Another thing is a brick tandoor. The unique design of the furnace allows you to forget about unambiguous meat. Each piece will be extremely tasty and crispy. Moreover, in Tandara, you can not only bake lamb, veal or pork. In it you can do delicious oriental cakes. Who not only beat your family and friends with an exquisite taste, but will be useful for health.

What is the tandar

This furnace is similar to most structures of this type, but has some differences. The main material of the inner surface is ceramics. Coal, twig or firewood can be used as fuel.

In their appearance, the tandoor from the brick, resembles a clay jug, covered by brick. The fuel is placed right inside and set on fire. As soon as the tree turns into coals, kebabs are laid inside the tandora. They can be placed with a sharp end on the foundation or hang for the hook on a pre-prepared porchochka.

Important ! The indisputable advantage of the tandoor of the brick is the long preservation of the heat. This allows you to make not one batch of delicious baked meat.

This furnace came to us from the distant Mesopotamia and later became extremely popular among the peoples of Asia. As a result, many oriental cuisines are hard to imagine without this wonderful car.

How does it work

Consider an example of a classic Uzbek tandoor of bricks. This furnace in appearance can be compared with the clay boiler. That's just turned upside down the bottom, changing the bottom and top of the places.

At the bottom there is a special hole, it is also called a subdomin. The clay base is traditionally placed by bricks. A small layer of air is formed between the clay base and brick. It must be filled with salt or sand. The first option is preferable.

Coal is stacked through the top hole. There are also versions of a tandoor of bricks with a side hole, but in the traditional Uzbek version, this design is practically not used.

Important ! At Tandara from the brick made with their own hands, there is one significant drawback. The ash has to be removed through the upper hole, and this is not entirely convenient (portable structures does not concern it).

For greater convenience of cooking kebabs in the Uzbek version there is a special lattice. Of course, you can put vegetables or pieces of fish on it. Equally good baking is guaranteed.

Attention ! If you correctly make a tandoor from brick with your own hands, then you can cook food for 6 hours after one extract.

The secret of such incredible heat-saving characteristics lies in the materials used when creating a structure. All of them have phenomenal properties on heat accumulation. With proper diligence of the furnace wall, you can warm up to 400 degrees Celsius.

If you are cooking, and not meat - the walls will preliminarily need to be cleaned of carpentry and ashes that could accumulate from previous sessions of the extracts. It is in the tandyra of a brick, you can cook, such popular Uzbek cakes are now.

Tydandora types

The type of tandora is first of all depends on the place of its installation. Depending on this parameter, such varieties are distinguished:

- jam Tandara

- portable tandoor

- ground tando.

We will consider the construction process of precisely the terrestrial tandora from the brick. The fact is that a nuclear tandoor is predominantly used for the heating of the premises, and the portable is a certain variation of ordinary mangal.

Step-by-step instructions Tandora

Training

Any important project begins with training. Of course, from the point of view of building science, the tandoor of the brick is not called a complex structure. Nevertheless, in order to create a solid and easy-to-use oven, it is necessary to carefully prepare.

The preparatory process begins with the collection of necessary materials. Since the constructions of the tandoor of the brick there are several, then the basic set can be very different. In our case, it includes:

- one hundred fifty kilograms of sandy gravel mixture;

- mesh mesh (each cell 5 cm) - two square meters;

- six or seven kilograms of cement M40050;

- fiber from asbestos - six kilograms;

- chamotte brick 50-70 pieces;

- fireproof paint 1 liter;

- fiberglass fittings of six millimeters in a section (at least 15 meters);

- refractory mixture for masonry - 20 kilograms;

- steel wire with a cross section of 3 millimeters -15 meters.

When the entire set of materials for creating a furnace is assembled, you must take care of the toolbox. Most of them can be found in the utility room of any country house, but some will still have to buy. To build tandara from brick, you will need it:

- plaster rule

- the container in which concrete will suffer

- putty knife,

- bulgarian,

- diamond circles for work on ceramics,

- paint brush.

As you can see, the list of necessary tools is not very long. Collect this set will not be much difficulty.

Foundation

The tandoor from the brick will work in the open sky. Therefore, he needs a reliable foundation that can provide a sustainable position of the design. A lot depends on the soil on which the construction will be built. If the soil is clay, it will take a reinforced foundation.

The best option for working on heavy soil is a column foundation. If the soil is lightweight and consists mostly from the sand, just get the monolithic concrete slab. This will be more than enough.

The tandoore area of \u200b\u200bthe brick will be 100 per 100 centimeters. To withstand this design, the thickness of the plate must be at least 10 centimeters. All over the perimeter of the foundation, it is necessary to remove the soil by 15 cm deep.

Important ! In the corners of the future slab you need to make a recess in 70-90 cm. Their diameter should be no more than 12-15 cm.

After the holes in the corners are drilled, it is necessary to reinstall them. We will need six millimeters with dimers here. At the end, steel structures are poured with concrete.

The recipe for the creation of the desired consistency is as follows: Take three parts of the sand, pour one part of the gravel (fraction size up to 1 cm) and as much cement by the brand is not worse than the PC 400. As a result, it will remind a thick sour cream of gray.

It is very important to correctly calculate the amount of solution desired for pouring. It is best to focus on the pit. To prevent discrepancies in levels, use the formwork. Place it on the bottom of the five centimeters high. In order not to spend time on the location of wooden structures, take a carbar tape.

On the bottom of the pit need to pour sand. The height of the layer cannot exceed the height of the formwork. The sand is watering water. This allows preventing the formation of a cavron. Only then can be laid formwork for the monolithic plate.

Important ! The layer of sand in the foundation plays the role of a damper pillow.

The formwork for the monolithic plate under the tandoor of the brick, is presented with your own hands, it is best to make from ordinary roofing boards. Their width should be exactly 15 centimeters, ten of which fell into the ground, and only five rise above it. A reinforcing grid is laid on the sand.

Important ! Before pouring concrete, it is necessary to align everything with a level.

Concrete setting time is at least 72 hours. Ideally, you need to wait seven days before installing the bake of Tandan to a new foundation. If the fill occurs in the summer, the foundation should be watched from time to time to prevent drying and as a result - the formation of cracks and chips.

Base

For the foundation you need chamotte brick. Note that the combustion temperature of coal is very high and conventional red blocks of burned clay may simply not withstand a similar load.

Chamotal brick has not only outstanding refractory properties, it also does not absorb moisture and is quite dense to withstand the weight of Tandara.

Another important plus chamotte brick is its resistance to temperature drops. That is why it is ideal for creating a tandyard outdoor furnace. Such a brick perfectly tolerate frosts and does not crack with the arrival of warming.

The base of the furnace should be done in the form of a circle. To do this, take the appropriate pattern and out of chalk. The diameter of the pamal is exactly 75 centimeters. Stay bricks in order. And only at the end with the help of a cutting circle, cut off unnecessary parts and angles, forming the perfect base.

Attention ! On the concrete base, you need to put the runneroid. It will ensure reliable waterproofing.

Take a refractory stove for chamotte brick and dress it carefully. Further apply it to the rubberoid.

Rule

The masonry rule is made with the calculation that the base of the tandoor from the brick must correspond to its height. The ratio of the neck to the base is 1/3. For the assembly, you will need a six-meter pole height. The base length is 30 cm.

Attention ! The step between the guides should be 25 centimeters.

To make molds take a piece of plywood. Ideal for lamella beds. The part on which the mattress is stacked.

Making the walls of Tandara

Bricks need to lay vertically. Therefore, it is necessary to spend a sufficient amount of solution so that the structural elements are firmly held together. The inner edges of Tandara's bricks should go close to each other.

Important ! All seams need to be thoroughly missed with a solution.

The first row of a tandan of brick is tightened with steel wire. After the design is fastened, the wires of the wire are twisted and hiding in one of the seams. You also need to be done with the second and third.

In the second row of Tandara from the brick, covered with their own hands, bricks cut into a wedge. The inner facet is laid as close as possible, the external, in turn, is thoroughly labeled with a solution.

After the construction of the main design of the tandoor from the brick is completed, you can start plaster. For this you will need a special oven. Its thickness should not be less than 10 mm. The top edge is made in the form of a roller.

Wait until the layer of plaster dries. For all this period, the tandoor of the brick is covered by cellophane film. This precaution is necessary to protect the design from harmful external factors, such as rain and straight sun rays.

Important ! Excessive heat can harm the unfinished tandoor of bricks to the same extent as high humidity.

After the plaster hardens, it will be necessary to cover the surface of acrylic refractory paint. You can also use bliss. Before use, it is necessary to clean the inner space of the tandoor of the brick from the dirt and the influx. For this work, a special broom is ideal.