Having made a jigsaw with your own hands, it will be possible not only to purchase a practical tool, but also to save money: it will be much cheaper than the factory counterpart, while having a full range of functions. A homemade jigsaw will allow you to create products of complex shapes from wood, plastic and other materials, the production of which with a hand tool under normal conditions would take a lot of time and effort.

A homemade jigsaw allows you to make cuts of complex shapes.

You should consider the structure and sequence of manufacturing a simple desktop electric jigsaw, assembly features and the procedure for working with it.

How does a jigsaw work?

As the name implies, this tool is designed to be positioned on the surface of a desktop or workbench. The compact size allows you to work with a jigsaw in a workshop or garage, as well as at home. An electric jigsaw is an indispensable tool for making intricate wood decorations, curly plywood carvings and the like.

Kinematic diagram of the jigsaw drive.

It is necessary to consider in more detail the structure of a factory-made desktop jigsaw. This will allow you to understand the main features of the device and apply them in a homemade model.

The components of an electric jigsaw can be roughly divided into 3 parts:

- movable frame with a saw;

- fixed base;

- Electrical engine.

The principle of operation of the tool is as follows: an electric motor rotates a crank mechanism, which turns rotary movements into reciprocating ones. The movements are transferred to a movable frame on which the saw is stretched.

A homemade device works using the same principle. To simplify the design, the movable frame can be replaced with a conventional hand jigsaw.

Back to the table of contents

Electric Jigsaw Parts

When assembling an electric jigsaw, it is important to find a suitable motor that will drive the working tool - the saw. For this purpose, a motor from a drill, blender, food processor or other equipment of the same type is perfect.

The jigsaw frame is best made of aluminum pipe.

The movable frame is made of metal profiles, wooden planks or sturdy plastic slats. It is most convenient to work with square-section aluminum tubes, since they are easy to process, have a low weight and a significant margin of safety.

To fix the jigsaw in the desired position, a reliable frame of wood or metal should be made for it. The dimensions of the frame do not have much effect on the performance of the jigsaw. They only depend on which version of the tool you need - a compact benchtop or a full-size floor-mounted one.

A jigsaw table is made of a thick sheet of plywood, in which a small diameter hole is made where the file will move (Fig. 2).

Between the body and the table is placed a gasket made of elastic material - rubber or leather, which will damp vibration.

There is also an easier option for how to make a homemade jigsaw. It consists in the fact that a manual electric jigsaw is mounted in a vertical position in a table-stand, while its file is attached tightly to the movable guide rails - levers.

Back to the table of contents

Assembling a jigsaw

Designing a homemade jigsaw begins with assembling the body, which can be made of plywood, chipboard or metal. The simplest model of this tool can do without a case, but in this case, strong vibrations occur, which can significantly affect the convenience of work. In this case, two holes are made in the jigsaw - one for attaching the crank to the tool, the second for movably fixing the jigsaw itself to the table. After starting the engine, the jigsaw begins to produce reciprocating movements, contributing to sawing the material.

This spring will provide the correct tension on the jigsaw blade.

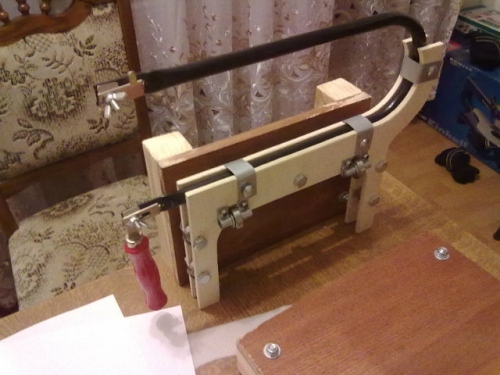

The more sophisticated model includes two separate strips, into the ends of which wing nuts are installed. From the opposite end, the slats are pulled together by a strong spring, which provides a constant tension on the saw. Such a device works from a separate engine or, for example, from a drill.

Inside the body there is a vertical bar, which is fixedly attached to its bottom or one of the walls. Two holes are made in it, the distance between which should be 2-3 cm less than the length of a standard file. Bolts or pins are threaded into the holes, onto which the strips holding the file are put on.

The engine is built into the housing and is attached to the lower bar by means of a disc with a connecting rod mechanism. A table with a hole for a file acts as a cover for the body.

The main disadvantage of a jigsaw with a separate engine lies in its most intricate part - the crank mechanism. The saw with it makes not only vertical, but also oblique movements, which cannot but affect the cutting accuracy. If you need to get an accurate tool, then it is better to replace the engine with an inexpensive factory-made manual jigsaw. It is fixed under the surface of the body and a file is threaded through the table, clamping it with one end in a jigsaw, and with the other in the upper bar of the structure. This design provides sufficient cutting accuracy, bringing this parameter closer to the factory models.

Back to the table of contents

Benefits of working with an electric jigsaw

The jigsaw allows complex cuts to be made very accurately.

Unlike hand tools, the electric jigsaw has clear advantages, including:

- higher speed of work;

- the ability to work with two hands, which increases the accuracy;

- safety - with the correct organization of work, a stationary tool is much safer, since it cannot escape from the hands.

In addition, making an electric jigsaw yourself will save money, since factory machines of this type are quite expensive.

A desktop jigsaw is useful for every craftsman cutting fine details. However, it is far from always possible and meaningful to acquire a full-fledged machine. In this case, get down to business and do it yourself!

Jigsaw device - what's inside?

Jigsaw machines relate more to special tools than to devices that are needed by both an experienced craftsman and an amateur who runs a garage. Their purpose is reduced to a special task, namely, cutting out complex curved contours from sheet materials. The special "trick" of such machines can be attributed to the execution of the cut without violating the integrity of the outer contour. Most often, sawing takes place on wood and derived materials (plywood, chipboard, fiberboard), although modern machines equipped with appropriate nail files are capable of working with other materials, for example, plastic or drywall.

Such equipment has found application in the music industry (making musical instruments) and, of course, in the furniture industry. Such units are also bought by lovers of tinkering in their own workshop. The device of a traditional jigsaw machine, designed according to all the rules, looks as follows: the working surface, on which the saw is brought out, hides the drive (electric motor) and the crank structure under it. The tensioning mechanism can be located both from the bottom and from the top of the machine.

To process a part, it must be placed on the work table. Many models have the ability to rotate it at different angles to make bevel cuts. Stops and guides on the surface, as well as the swivel mechanism, can be marked, which greatly simplifies and speeds up the work. The length of the cut depends on the length of the working table - most models are limited to 30-40 cm. The power of the electric motor is an important, but still far from the most fundamental factor, since the machine has a huge reserve of unclaimed power. For example, for a home workshop or even a small production, an "engine" of only 150 watts is enough.

The crooked connecting rod mechanism is a much more important detail, because in this case it is on it that the quality of the transmission of the drive torque to the forward-reverse movement, directed in the vertical plane by means of a file, depends.

Standard jigsaw machines are devices with an amplitude of movement in the region of 3-5 cm at a frequency of oscillations of up to 1000 per minute. Many models provide speed control for different materials. The jigsaw itself is usually made up to 35 cm long and is capable of sawing material up to 10 cm thick. The width of the files can vary in a fairly wide range - from very thin two-millimeter to coarser ten-millimeter, with a thickness of 0.6 mm to 1.25 mm.

Even the thickest and widest file will break easily if you do not provide sufficient tension along the entire length of the file. For this, spring and coil springs are used. Quite often, such machines are equipped with an air pump, which cleans the cut from sawdust by blowing, as well as a drilling unit. The latter device is especially useful, because in this case the master does not need to be distracted by connecting an electric drill and drilling a hole - everything happens on the working plane of the machine. Of course, you have to pay for the convenience!

How to make a do-it-yourself jigsaw from a manual jigsaw?

On the web, you will find many different designs of homemade machine tools, but most of them boil down to repurposing into this machine. Using your ingenuity and watching the video, you can quite easily make a homemade jigsaw machine from this tool. You only need to modify the jigsaw a little. In fact, it plays the role of a machine drive and a crooked connecting rod mechanism, the rest needs to be thought out and implemented.

Of course, manufacturers are trying to please consumers in this area, offering their platform options for quick and convenient rework, however, in reality, only you can make the device that suits your needs... So, the first step is to make a support table, for which sheet metal is most often used. In it, you need to make a sloping oblong hole for the saw blade and holes for fasteners (countersunk screws are recommended), and attach the jigsaw to the bottom of the support table.

This structure can only be strengthened on a wooden table. You can go beyond this and install the guide rails. The convenience of such a device lies in the fact that in addition to performing functions that are not entirely inherent in it, you can always disconnect the drive and, with a slight movement of your hand, turn it back into a manual jigsaw! If you constantly need this tool for work, it makes sense specifically for the machine - it will be cheaper than spending money on a real machine.

Advantages and disadvantages - continue to modify!

But such a unit inherits not only the advantages of the tool, but also its disadvantages, in particular - a file that is too wide for filigree work, which significantly limits the curvature of the lines. If there is a need for this, there will be a way out. So far, our machine differs from the classic jigsaw unit by the absence of springs that would provide sufficient tension for the file. But it is quite easy to build a simple rocker, which on the one hand will be under the tension of the springs, and on the other is fixed on a nail file.

There is another option - to clamp the nail file between two guide rollers, but the first option is still safer. Remember to turn off the jigsaw pendulum before using your homemade jigsaw. There is another design - if your tool is powerful enough, then it can only serve as a drive in a design of two rocker arms, between which a file is stretched. The movement is transmitted by means of a file attached to the lower rocker arm.

A machine from a sewing machine - giving a second life to old tools!

If you inherited a foot or hand sewing machine from your grandmother or mother, consider yourself the owner of an excellent jigsaw machine! Of course, for this you need to "conjure" a little over the typewriter. First, remove the thread braiding device, which is usually located at the bottom of the machine. There is nothing difficult about this, just unscrew the two bolts. Then we knock out the cotter pin and remove the drive shaft leading to the thread weaving mechanism.

Having unscrewed the upper panel that protects the mechanisms, it is necessary to widen the slot in which the needle went. Be guided by the needs and width of the file that you will use in your work. Jigsaw blades of this kind also need to be slightly modified, namely, cut to the maximum length of a needle that could be used on this machine. After grinding off the upper teeth and sharpening the lower part on the point, you just need to insert the file into the needle holder and test your machine in action!

A tabletop jigsaw is an indispensable thing for any owner who is accustomed to independently cope with household chores. Electric jigsaws are especially good for residents of the private sector, lovers of manual labor and summer cottages. From its prototype, an ordinary hand-held jigsaw, the desktop electric model has gone far enough. The tabletop jigsaw allows you to facilitate and speed up the cutting procedure, not to mention improving the quality.

The concept of a tabletop jigsaw

A jigsaw is a saw, which is characterized by the reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving over the surface that is being processed, and makes movements with a frequency of up to 3000 vibrations per minute.

This tool was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in the sewing machine with a blade. The instrument appeared on the market already in 1947. The manual jigsaw has a flat platform body and a handle. The main difference between an electric jigsaw and a manual jigsaw is its greater functionality and cutting quality.

Inside there is an electric motor and a special mechanism that drives the blade. In stationary jigsaws, the handle is absent, and the platform is located on top. In the front of the mechanism there is a guide, in the lower part there is a retractable canvas that moves and makes cuts.

The tool works as follows: a file for a tabletop jigsaw is securely fastened with clamps in the slider. Reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part to be cut, so the work is carried out very precisely.

The purpose of the table jigsaw

The jigsaw is an integral part of every workshop and every hobbyist. Its thin file can successfully separate plywood, copper, iron, thick boards, brass, steel. The tools can be motor driven, foot driven or hand driven and are more powerful. An electric jigsaw is simply irreplaceable for joiners, woodworkers, furniture decorators, drywall makers, making complex parts.

The electric jigsaw can make straight and curved cuts on workpieces with complex shapes and various sheet materials without disturbing the outer contour. Most often, table jigsaws are used to cut wood and wooden slabs, figures with a complex outline made of laminate and drywall, plastic blanks, and also for cutting sheet metal.

The benchtop electric jigsaw makes clean, complex cuts and works fine

details. Due to the stable and fixed position during operation, a high cutting accuracy is achieved. The saw has a stable ride thanks to the tensioning system and guides, which manual jigsaws do not. The large size of the table makes it stable, so the exact cutting direction is observed.

Types of jigsaws

Today, a wide variety of jigsaws is presented on the power tool market, which differ in the nature of their application, technical characteristics, type of power supply and design features. In hardware stores, you can buy a desktop jigsaw for every taste and wallet.

It is difficult to classify by design features, because each manufacturer seeks to provide its products with features that are designed to facilitate and improve the operation of the tool. In this respect, the shape of the handle is an important parameter.

There are two types of handle - mushroom and D-shaped. The staple jigsaw requires one-handed operation. This increases the possibilities of using a jigsaw, however, it somewhat negatively affects the quality of the cut of the material.

Mushroom handles suggest making more accurate cuts when holding the jigsaw with two hands, after fixing the workpiece to be cut. The choice of a jigsaw with a specific handle shape depends on the financial capabilities and personal preferences of the buyer. It is worth choosing the jigsaw with which it will be more convenient to work.

Household jigsaws are not intended for intensive use, but the low price of a tabletop jigsaw and the power that is enough for household needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of daily use for many hours (up to 8 hours). The significant power of such jigsaws allows you to process materials of great thickness. Extended equipment and improved performance are reflected in the price.

Among professional jigsaws, industrial ones also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

According to the type of power supply, there are network and battery jigsaws. Mains models are supplied with standard voltage mains. If performance is important to you, then it is worth choosing a corded power tool.

Cordless jigsaws provide independence from the presence of outlets and more mobility during work. When buying a rechargeable model, you should pay attention to the type of battery. The increased performance is inherent in lithium-ion batteries. The capacity of the battery is responsible for the duration of operation without recharging.

Advantages of desktop jigsaws

A tabletop electric jigsaw is a stationary design, so this type of cutting tool has many advantages. Modern models can work with wood materials 40-50 millimeters thick. A narrow saw acts as a working body, which makes vertical reciprocating movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the saw, the material is cut by an upward stroke.

The tabletop jigsaw allows you to cut complex decorative details, make longitudinal, straight, oblique and transverse cuts. The wide table top allows you to machine large parts and make cuts inside wide workpieces. A secure mount protects the body from unnecessary vibrations and allows for good material placement, so the motor can work without overloading.

The advantages of table-top jigsaws are good accuracy and precision of cuts, high safety and ease of use, wide customization options from the material and the required part of the cut blanks.

If you need to cut small parts, a manual jigsaw will not be very convenient. It is quite heavy, so you have to hold it with one hand and guide the workpiece with the other. A desktop jigsaw is devoid of this drawback. Perhaps the disadvantages are the too large dimensions and the complexity of working with large details.

The tabletop jigsaw is a kind of mini machine for cutting workpieces. If you buy a jigsaw in a store, most likely there will be the ability to select the power and adjust the frequency of the saw strokes. However, you can make the simplest homemade tabletop jigsaw very quickly. You will need a manual jigsaw, a few screws, a small piece of plywood and only an hour of work.

Making a tabletop jigsaw

A neatly made jigsaw will not be inferior to a factory-made one, and in some respects even surpasses it. It is not difficult to assemble such a jigsaw if you have the necessary materials. Next, we will describe a simple scheme of such manipulations.

The jigsaw design includes the following components: handle, switch button, insulating washer, power cord, frame, heating thread, screw clamp and shackle. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind that the lighter the frame is, the more convenient the jigsaw will be to use. Be sure to provide a conduit so that the power cord can be routed later. The best frame shape is one with one side angled 45 degrees.

Next, you need to make an earring. It is made of copper sheet one millimeter thick. After that, it is attached with screws to the frame, where it connects to the handle. Thus, the screw, wing nut and shackle will form a clamp in which the heating thread can be fixed. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make hold-down cheeks from it, between which there is a button-switch.

After that, you need to cut a gap in the plywood through which the file can pass. It can be done with a drill. To do this, you need to drill holes along the marking line, and smooth the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill the mounting holes on the plywood and the base plate of the jigsaw.

Then you need to fix the jigsaw with screws on the plywood base so that the file can go through the gap. You attach the structure to the table with a clamp so that the file points up. You can also pin the platform in any way you like.

The jigsaw file remains common, but the possibilities for good cutting are expanded by freeing up the hands.

You can use a nichrome coil from any household heating device (iron for example) as a heating thread. It must be tightened with tension between the ends of the frame bends. To warm up the thread, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome filament. With the help of a rheostat, it will be possible to set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the thread heats up. Before starting work, you need to determine the current strength. But keep in mind that if the force is too high, the material to be cut can be seized by the flame, and if it is insufficient, it will not. A do-it-yourself desktop jigsaw will allow you to cut shapes with complex contours from various types of materials.

Rules for using a tabletop jigsaw

When working with a desktop jigsaw, you must adhere to some rules:

- When cutting, do not press hard on the tool, otherwise, at best, the needle will break, at worst, you will ruin the work.

- Replace saws from time to time. An old saw can ruin and erode the surface of the material.

- If you work with organic glass and non-ferrous alloys, the surface of the product must be moistened with water. Such an operation will speed up the process and extend the life of the saw.

- If you are cutting a surface less than one millimeter thick, place a sheet of wood or plywood under the material to be cut.

- The material must be secured before cutting. It is better not to make long cuts by hand, the line may turn out to be curved.

- For cutting different materials, appropriate blades are required, with a special pitch and length.

- Turn the tool by turning only the back of the tool.

- When cutting the laminate, adhesive tape is glued to the cut line, which protects the material from chips.

- If curved cuts become necessary, set the jigsaw pendulum to minimum.

If you have not yet fully understood how to make a tabletop jigsaw, watch the video about this procedure. This tool allows you to cut complex parts from wood and other material, to make longitudinal, oblique, straight and cross cuts. With the help of a jigsaw, you can process large parts, wide workpieces and small products, which is not superfluous at home.

What to do when you need a jigsaw but you don't need to buy one? You can make a jigsaw with your own hands; there are many ways to make or repair such a tool. Let's consider the simplest and most affordable ones.

Manual jigsaw - simple, fast and affordable

How to make a jigsaw quickly from affordable and inexpensive materials? Here's the easiest way.

List of tools and materials:

- plywood sheet (10 mm);

- plywood sheet (4 mm);

- steel sheet (2 mm);

- bolts and nuts;

- drill;

- chisel;

- sanding paper;

- file.

The base of the hand jigsaw is a bracket; it should be prepared from a plywood sheet (10 mm). Further, it is recommended to make the nubs for the tool handle from thinner plywood (4 mm). These nubs must be glued to the handle on both sides, which will ensure more convenient later on. The staple and handle should be finely sanded with sanding paper and a file. Cut out the steel plate with a chisel and then file the clamping jaws. After that, drill the slots in the jaws with a drill, and then cut out the notches inside the clamping jaws with a sharp chisel. In the left-hand clamping jaw, modify the slot for the bolt, for this you need to make a thread. Attach the jaws to the bracket, then screw the bolts into the left clamp, securing them with nuts.

Back to the table of contents

Desktop jigsaw: two production options

The tabletop device can be made both new and by means of revision or repair of improvised means.

Making a new desktop power jigsaw will require the following tools and materials:

- duralumin pipe;

- plastic base;

- clamps;

- screws;

- copper sheet;

- drill.

First you need to prepare the frame, for this purpose it is better to use a duralumin pipe. In the manufacture of the frame, it is necessary to provide a passage through which the cord will be laid, providing power supply. A copper sheet should be taken to make a U-shaped frame, which will subsequently need to be attached to the frame itself. At the junction of the frame with the handle of the jigsaw, screw the frame with screws. In the plastic base, drill a hole for the file with a drill, as well as slots for fasteners. Fix the jigsaw on the prepared plastic so that the file passes through the hole. Using clamps, attach the finished instrument to a flat surface such as a table.

A hand-held device made on the basis of a sewing machine is ideal if repairing a sewing machine is not as important as making such a tool. List of tools and materials:

- sewing machine (both foot and hand models can be used);

- file;

- file;

- drill.

Having unscrewed the bolts at the bottom of the sewing machine, remove the entire threading system. Next, knock out the metal fastening rod and remove the drive shaft of the thread braiding system. The panel covering the sewing machine parts can be easily removed by unscrewing 2 more bolts. Remove the needle carefully. The needle slot requires minor repairs - it needs to be widened to accommodate the file. To do this, it is better to saw the hole with a file, focusing on the size of the file itself. After that, adjust its size to the maximum possible size of the needle by cutting off the upper part of the file. After filing the upper teeth with a file, and the lower part on the point, you can proceed to the next step. The prepared file must be put in place of the former needle - in the needle holder. After that, turn the wheel and check:

- so that the saw does not come into contact with the panel and the presser foot;

- so that in the upper position the plywood passes freely under the saw;

- so that the stretching of the material runs smoothly.

Such a jigsaw is suitable for working with materials made of plywood, balsa wood and plastic, and if you use an electric machine, you get an electric jigsaw.

After several unsuccessful attempts to cut out complex shapes with an electric jigsaw, I decided to make a homemade desktop jigsaw according to the drawings from the network. It will be very easy to cut complex shapes of small sizes from light materials on it.

To assemble a jigsaw with your own hands from a jigsaw, you will need:

- electric jigsaw

- plywood sheet and boards for support

- screws for wood

- bolts with nuts

Tools: drill, sandpaper, clamp, tape measure.

Step 1: cut out the cover and base

Draw two 250x300mm rectangles on a piece of plywood and cut them out with a jigsaw. These rectangles will be the base and cover of your machine. Carefully sand the surfaces of the rectangles with sandpaper, especially the one that will be the lid.

Step 2: making the front pillars

Show 4 more images

Measure the height of the jigsaw from the sole to the handle so that the jigsaw fits in the machine box, the posts should be greater than this distance. My jigsaw is 18 cm high, so I made racks 20 cm long from the board.Then I squeezed the two pieces together with a clamp and sawed off 5 mm from both sides so that both racks were the same height.

The posts can now be screwed onto the base. To prevent the wood from cracking, you must first drill the holes for the screws and countersink them.

Step 3: attach the jigsaw to the lid

Show 7 more images

- Remove the sole from the jigsaw using the included hexagon. There is already one hole in the cover, you need to drill three more so that there is a mounting hole in each corner.

- In the center of the plywood cover, mark where you will attach the sole of the jigsaw and the hole for the jigsaw blade.

- You can now drill four holes in the plywood by countersinking them with a feather drill so that the screw heads are flush with the surface. It remains to make a hole for the file.

- Now slide the sole back onto the jigsaw skis, and place the plywood cover over the sole so that the file goes through the hole provided for it.

- Insert a washer into the expansion of each mounting hole, insert the bolts into the holes and tighten them on the other side with nuts. It was a little difficult to tighten the bolts, so I fixed the head of each bolt with a flathead screwdriver, and twisted it on the other side with a wrench.

Step 4: install the jigsaw on the base

Lower the cover with the jigsaw onto the base with the posts and fix it on top with screws, having previously drilled holes for them. Remember to countersink these holes to prevent the wood from cracking when screwing. The jigsaw should not touch the base and should grip the lid well. Therefore, the heads of the screws must be flush with the surface of the cover, otherwise they will unfold during the operation of the jigsaw.

From the remnants of the board, I made two additional rear posts, so the machine became much more stable.

Step 5: machine rework

At this stage, the machine is quite functional, it is enough to simply fix it with a clamp on the table top and you can work.

I found two things about my jigsaw:

- the canvas walked a little to the sides, especially when working at high speeds.

- the width of the blade was wider than that of standard jigsaw blades, which left a lot to be desired when cutting especially fine holes.

Step 6: reduce the width of the canvas

A narrower blade will allow you to cut through fine curves and make it easier to cut rounded corners.

- Extend the file to the maximum, do not forget to unplug the jigsaw.

- Mark the point where the blade exits the case. Nothing needs to be removed below this point.

- Remove the file from the jigsaw and grind the blade to the desired width on a sander. While sanding, dip the file in cool water so that it does not overheat, otherwise the metal will lose its hardness and the file will not be able to cut through anything. Color change is a sign of metal overheating.

- When you get the desired blade width, put the saw back into the jigsaw.

Step 7: making a file guide

The guide will prevent the blade from wandering to the sides during cutting, especially at high rpms.

I made the guide from a small strip of PVC plastic. At one end of the strip, use a jigsaw to make a small cut at an angle to the middle of the strip. We fix the strip behind the file by screwing it to the wooden L-shaped piece fixed to the lid of your machine. The guide can be lubricated with oil for better movement.

Remember:

- The guide should never be higher than the blade at the lowest point of the blade's path.

- The guide limits the size of the material you are going to cut due to its height and attachment point on the surface. Therefore, it is better to fix the guide as high as possible (taking into account the previous remark), and as far away from the canvas as possible, with a slope to the side, as soon as possible.

Step 8: Conclusion

With a little bit of effort, you have an almost real desktop jigsaw. Of course, it will not replace a real machine, but given its zero cost, it is an excellent option.