Incorrect inclusion of heating radiators - factor that most often causes problems during operation.

Errors in the installation of other components and the wrong choice of system type also have a negative impact on the use of heating devices.

How to properly connect batteries in an apartment building

Connection options depend on the number of pipes used to connect the boiler to the radiators. There are two methods:

- One pipe comes out of the boiler, makes a circle along the harness, simultaneously entering the batteries, and returns to the starting point. This installation method is easy to implement.

- The first half of the system exits the heater, visits all radiators, connecting with them only once. At the extreme, the most distant, it stops and the second part begins. The latter also passes through all the batteries, connecting on the other side. Its end point is the cauldron.

The choice will depend on the budget, as both options have advantages over the other. Single-pipe is easier to install and cheaper, which is why it is used in apartment buildings. Two-pipe is more complicated and more expensive, but more reliable, therefore it is recommended for private buildings.

Schemes for the correct connection of radiators to the heating system

Pipes leading to radiators in three ways:

- Diagonal variant implies a supply connection with the upper axis on one side of the battery, and a return connection with the lower one on the other. This type is characterized by high efficiency and fast heating of sections, regardless of their number and distance from the boiler.

Photo 1. Scheme of diagonal connection of a heating radiator. The supply circuit is on the top left, the return circuit is on the bottom right.

- lower connection is made along one axis. To do this, the supply is cut from one end of the radiator, and the return from the other. This method is used less frequently than others due to poor performance.

Photo 2

- Lateral also known as unilateral. Pipes are fed from one side in a vertical plane. This method is in great demand in small rooms and apartments.

Each type of connection can be used because they independent of the heating system. But in the work of different combinations there are nuances that it is desirable to observe.

Reference. Single-pipe wiring is better combined with bottom and side connections, and two-pipe - with diagonal.

Wrong connection methods

Radiators are usually mounted without problems, but the same cannot be said about some components of the system.

Thermostat head

Errors during installation of the device lead to a drop in performance. The most common problems are:

- Vertical head placement make sure that it does not stick out to the side, interfering with walking or cleaning. This causes the bellows to heat up as the coolant rises up from the valve. To correct it, it is necessary to stop operation, dismantle the device, then reinstall it, placing it horizontally.

Photo 3. Incorrect vertical connection of the thermal head to the battery (left), correct horizontal placement (right).

- Placing the thermal head in a niche or similar confined spaces. This leads to a decrease in convection: heat settles in a closed volume, accumulates and is incorrectly reflected from the surrounding walls. Thus, the heating efficiency is reduced.

- Installing curtains so that they cover the thermal head. This factor leads to an incorrect determination of the temperature in the room by the device. The bellows stops working when it is needed. Solution to this problem — removal of the sensor on the wall, not covered by unnecessary objects. Most thermal heads are allowed to be mounted at a distance of up to two meters from pipes.

- An important role is also played by the quality setting of the device. It is recommended to invite a specialist who will check the correct operation and, if necessary, change the characteristics.

You will also be interested in:

bypass

Problems with the device usually arise when radiators are replaced by an unskilled person. This is especially true in cases in which cast iron is exchanged for another material.

The two most common mistakes are:

- Mounting on the supply bypass pipe of the ball valve designed to let water into the system. The entire coolant should not pass through the device: only a small part, which is enough for operation.

- The bypass is connected to the piping through a mixer with a three-way valve. Theoretically, this allows you to regulate the heat transfer of the boiler, but in practice it leads to damage to the device.

Both errors are easy enough to fix by changing the principle of connecting the bypass. There are also a few rules to note:

- It is forbidden to install a bypass on a free pipe in apartment buildings.

- Forbidden installation of stop valves and valves.

- Allowed reduction of pipes by one typical size.

- In a non-volatile gravitational system pump needed, and it is connected exclusively to the bypass.

Attention! These problems relate exclusively to apartment buildings, in which they lead to imbalance of the whole system. The consequence of such errors is a decrease in the amount of heat that neighbors receive along the highway.

1.

2.

3.

4.

The heating system is created in order to provide heat to everyone who lives or is in a residential building, apartment or building, while the connection of heating radiators must be done correctly. Comfortable is considered to be the air temperature in the room in the range from 18°C to 25°C. The power of heating devices should be such that it compensates for heat loss through walls, doors, windows and other protective structures facing the street.

The scheme that determines the connection of heating radiators in your own house is selected at the design stage of the building before the start of construction work. True, measures to improve or repair the heating structure can also be carried out during the use of the premises.

Of course, if there is a central heating main in the settlement, the best solution to the issue of heat supply is to connect to it. In the absence of centralized heating, the arrangement of an autonomous heating system becomes relevant.

Factors affecting heating efficiency

The efficiency of the heating structure depends on several factors:- Wiring of elements of the heating system. The degree and uniformity of space heating, and, accordingly, the amount of money spent on heat supply to a house or apartment, depends on the correctness of this work.

- The choice of heating equipment. Everything that is needed to create a heating system is acquired on the basis of a professionally performed calculation of technical and financial indicators. The fact is that the decision on how to properly connect heating radiators and the choice of appropriate equipment contributes to achieving maximum heat transfer with minimal fuel consumption. See also: "".

- Mounting method main pipelines, heating boiler, circulation pump, connection of radiators, regulating and locking elements. An incorrect installation of any of the links of the heating structure can result in the failure of the entire system.

- Availability of special knowledge and skills carrying out works related to the design and installation of the heat supply structure. To perform calculations and determine the heating scheme of the house, including the option of how to connect heating radiators in a particular case, professionals in the field of heat engineering should. Despite the fact that the involvement of specialists will lead to an increase in the cost of arranging heating, you should not save on this. See also: "".

The choice of the connection scheme for heating batteries

When the choice of the type of heating boiler is completed, the scheme for connecting the heating batteries in the house is determined. It can be single pipe or double pipe.The radiator connection itself is performed in one of three ways:

- bottom;

- side;

- diagonal.

If, when deciding how to connect the heating battery, one-sided piping was planned, then the number of sections on one device should not exceed 12 for gravity heating networks and 24 for systems equipped with a circulation pump.

If it is necessary to install a larger number of sections, it is necessary to use a versatile piping connection to heating radiators. When installing heating appliances, one should not forget about the throughput of the straight pipe and the return pipe, which depends on their diameter and roughness coefficient.

Efficient heat transfer can be achieved if the batteries are optimally placed, or rather, if the installation distance of the devices is respected in relation to the walls, flooring, window and window sill.

Installation instructions and how to properly connect a heating radiator provides for the following standards:

- the device should be at a distance of 10 - 12 centimeters from the floor;

- it should be installed no closer than 8-10 centimeters to the windowsill;

- the back panel cannot be placed closer than 2 centimeters from the wall;

- when installing batteries, it is necessary to provide for the adjustment of the degree of their heating, both in manual and automatic modes. For this, special thermostats are purchased (more details: "");

- in order to repair or replace the radiator, valves, valves and manual taps should be provided. They will allow you to disconnect the product from the heating system;

- on the devices you need to put Mayevsky cranes, such as in the photo. With their help, air that has entered the system is removed.

- carry out preliminary marking for the placement of brackets that are attached to the wall;

- Mayevsky cranes are mounted on appliances;

- install various shut-off and other elements - valves, plugs, taps and regulators;

- before connecting a heating radiator, it is placed on brackets and aligned to a horizontal level;

- the device is connected to the pipeline using transitional runs;

- make pressure testing and test run of water.

Serial connection of heating radiators

With this method, the batteries are connected using one pipe. Most often, if a serial connection of heating radiators is required, then in order to increase the power of the heating devices and ensure a sufficient degree of heating of the room, it is necessary to increase the number of sections to the end of the line.

The series connection method is characterized by an uneven distribution of thermal power. As a result, the first of the radiators heats up much more than the subsequent ones, and the last device in the circuit will be barely warm.

Despite a number of inconveniences, this method is in demand due to its simplicity, and the desired degree of heat transfer is adjusted by building up several battery sections in different places of the heating structure. See also: "".

Examples of connecting heating radiators in the video:

Heating radiators. Ways to connect radiators. properties and parameters.

In this article you will learn:

Go...

At the sight of various radiators, eyes widen ...

I will help you quickly deal with the types and tell you about how to connect certain types of radiators.

We will not consider convectors and cast-iron radiators ...

You can learn about them from this article:

We continue...

To date, the most popular radiators are sectional: Aluminum and bimetallic.

Aluminum radiators

Working pressure up to 16 bar.

Bimetal radiators

Working pressure up to 20-40 Bar.

What is the difference between aluminum and bimetal radiators?

Some bimetal radiators are very similar in appearance to aluminum radiators.

Since in bimetallic radiators a steel one is hidden, covered with an aluminum shell.

Many write in their articles that it makes no sense to install more than 10 sections, but I say the opposite. There is a point, the heat transfer from a radiator with a large number of sections is much greater. The law of heat engineering.

20 section radiator. An example from life! Heats great!

If you decide to put up to 20 sections, then pay attention to the fasteners, four may not be enough. There are two types of fasteners in nature:

1. Corner bracket

2. Pin bracket

The corner bracket is suitable for flat plastered walls.

Pin bracket - for any walls. The only drawback is that the pin bracket will not hold well in hollow brick.

The best corner bracket is the one on which the wall with the mount is the largest in area. Such a corner bracket holds a horizontal position better without deforming downward bending.

Of the pin brackets, those with a thicker pin diameter are better, and better bursting in a cork. At the moment I like from the company "Omec".

Ways to connect radiators.

Consider a different set of connections. Below we will consider which connection is suitable for various schemes. For example, for apartment buildings with one-pipe systems and with two-pipe systems.

Advantages and disadvantages of each scheme.

1st place. Diagonal connection. The most efficient way in which there is a maximum consumption of thermal energy from the coolant. The disadvantage is the inability to change the number of radiator sections.

2nd place. Side connection. It does not lose much in terms of efficiency from a diagonal connection. If there is a question between options 1 and 2, I choose the side connection. Since if, for some reason, I am not satisfied with the power, then you can add (or reduce) the number of sections without alterations to the connection nodes.

3rd place. Bottom connection. There are many myths about this connection. And now I will say the disadvantage of this connection.

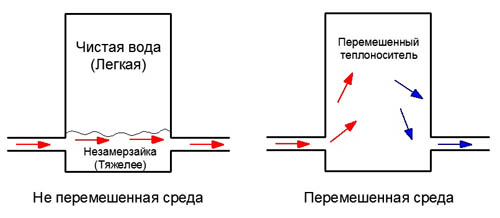

Flaw. For a private house. When you start pouring antifreeze into the system without thoroughly mixing it with a fraction of distilled water, a layer appears along the height (water / antifreeze). And, since the non-freezing liquid is heavier than water, it is lower than ordinary water. Therefore, a puff cake appears in the radiator by mass in the form of two different media: water and anti-freeze. This unstirred layer cake blocks the inside of the radiator. This phenomenon is similar to how you try to mix oil with water and, naturally, due to different densities, these two media (water and oil) will be on top of each other.

The incoming anti-freeze liquid in the radiator cannot rise up and mix with water, as it goes in a straight line. See picture:

Very often, I personally encountered such a problem that the top of the radiator remained cold. Even water that has cooled by 100 degrees will not become heavier than anti-freeze.

This problem is fixed as follows.

Through the Mayevsky tap, you need to pour out all the upper (light) water. And, at the very end, you will see when the anti-freeze of a specific color for it (blue, pink or green) goes.

As for smooth heating in a radiator with such a connection, this is sheer nonsense. And don't focus on it.

Connecting the radiator from top to bottom

This is the best that can be for the heating system. Trust my experience as a hydraulics and heat engineer.

In our company, when it came to laying central heating systems, we used only steel piping for piping. And this was not discussed, since they are being laid.

Advantages of steel pipeline for central heating.

For those who are not in the know. The steel pipeline is an ordinary iron pipeline. There is a galvanized pipe - it is steel (iron), coated on the outside with a thin layer of zinc. Zinc is harmful to the system, that is, to our health. Zinc protects steel from corrosion, but even zinc has deposits. There are chemical flushes to remove deposits.

Try to find a plastic pipeline with such parameters!

And in central heating systems, collapses such as:

Therefore, for central heating systems, a steel pipeline must be installed.

Plastic does not like temperatures already above 80 degrees. Especially polypropylene. By the way, the record holder for resistance to high temperatures. Of course, you can choose copper, but there were problems with copper too. Copper can be destroyed by stray currents in the pipeline with the touch of some metals. An example would be steel reinforcement in a wall. Contact of copper with aluminum and steel is also harmful. Tin solder at the joints does not like alkali, which is present in central systems. In practice, things happened when holes formed in the copper pipeline due to the contact of the copper pipe with steel fittings. Therefore, whatever one may say, a steel pipeline is better suited for central heating. Plus it's cheaper.

In order to avoid deposits in the steel pipeline, various additives are added.

But it's not as scary as it seems!

Above, I told the bike about all the advantages of a steel pipeline.

For central heating systems, cross-linked polyethylene, polypropylene, copper can be used. However, you need to know their features in full.

There are houses that have their own with a personal closed system. Therefore, if you decide on a plastic pipeline or copper, then you need to consult with a housing management company. In addition, in many boiler rooms there is automation that will not allow high temperatures and high pressure in the heating system.

Life does not stand still, and automation makes life easier for us. But there is always a risk that the automation will not work.

Therefore, by mounting plastic in the heating system, you act at your own peril and risk. Although, with each decade, these risks become less and less and gradually reduced to zero.

How to change an old radiator to a new one in central heating systems?

If this is a one-pipe system, then it is better not to touch the riser with a jumper and leave it as it is!

On the steel pipelines going from the riser after the jumper, you need to put repair valves to repair the radiator. It can be ordinary ball valves. After the taps, continue with steel or other pipelines to. It is better to put thermostatic valves on the radiator to regulate the temperature in the room.

Thermostatic valve on the radiator.

A thermostatic valve with a thermal head provides climate control to the room. That is, the thermal head itself, sensing the temperature in the room, changes the position of the stem at the thermostatic valve, the stem, in turn, closes or opens the valve passage. If it gets hot, the valve closes the passage to the coolant. If it is cold, the valve opens the passage for the inlet of the coolant.

Radiator installation

As for the installation of the radiator, the minimum distance from the floor according to the standard is from 10-12 cm.

From the wall 2-3 cm.

All these gaps affect the heat dissipation of heat from the radiator. The farther from the wall, the more heat. If you sink into the floor, this will also reduce the heat dissipation of the radiator. The minimum distance from the floor should be 10 cm. The maximum distance should be 15 cm. Also, there should be an opening for ventilation from the top of the radiator to the window sill.

And you do not need to push the chair and beds with backs on themselves - this reduces heat generation.

If your house is cold, then in your case it is contraindicated to cover the radiator with decorative grilles.

This system creates an equal length of pipeline to the radiator. This condition helps to create an even flow distribution between the radiators.

The fact is that there are resistances along the length of the pipeline, which affect the flow rate.

If you want to better understand what resistance is in a heating system, then you should get acquainted with such sections as:

Collection of photos for reflection:

All schemes are working, there are some shortcomings. These diagrams are for reference only...

| Comments(+) [ Read / Add ] |

What does the correct connection of a heating radiator look like? We will analyze the connection schemes used in private houses and city apartments, and pipes, fittings and elements of shut-off and control valves used for this purpose. In addition, we will find out what mistakes can be made when designing and installing a heating system.

Circuit diagrams

If in a city apartment the scheme of the heating system as a whole or its separate loop does not depend on our efforts, then in a private house the circuit is designed from scratch.

Two fundamentally different schemes can be distinguished:

- Single pipe, which is the only filling along the perimeter of the heated building. Heating appliances are cut parallel to the filling.

Note: consistent installation of batteries is also practiced; it is inconvenient because it does not allow independent adjustment of devices.

- Two-pipe- independent supply and return filling. Each radiator acts as a jumper between them.

The advantages of a single-pipe circuit are low cost, ease of installation and exceptional fault tolerance. Disadvantages - a significant temperature spread between the first and last heater, as well as the problematic laying around the perimeter of the house in the presence of high openings and panoramic windows.

The two-pipe scheme is devoid of these shortcomings, however, under certain conditions, it can create much more serious problems for the owner. The batteries closest to the boiler dampen the difference between fillings, which slows down the circulation in distant appliances. That is why the two-pipe requires mandatory balancing - throttling of the connections and adjusting their throughput to equalize temperatures.

This problem is gracefully circumvented in an associated two-pipe system, the Tichelmann loop, all loops of which are of equal length.

Insert radiators

What are the ways to connect heating radiators to spills and risers?

| Name | Description | Peculiarities |

| Lateral unilateral | The connections are connected to the upper and lower collectors on one side of the heater. | With a small number of sections provides maximum heat transfer. If the number of sections is more than ten, the edge of the radiator farthest from the connections will cool down. Silt accumulates in the outer sections over time |

| Bottom down | Liners are connected to both plugs of the lower manifold | The heat transfer of the device is slightly reduced due to slow circulation through the upper collector. The radiator does not require flushing: the sections do not silt |

| Diagonal | The connections are connected to the top plug on one side of the radiator and the bottom plug on the other side. | Heat transfer is maximum at any length of the radiator. The bottom of the sections is silted from the side of the blind bottom plug |

Please note: in a closed autonomous heating system, you can forget about the problem of battery silting.

A small amount of suspension contained in the coolant quickly collects in the sump and does not create problems in the future.

Accordingly, it makes sense to choose those types of connection of heating radiators that will provide maximum heat transfer.

Mistakes

Incorrect connection of heating radiators can lead to malfunctions of the central heating system, autonomous circuit or seriously reduce the heat transfer of the device.

What mistakes can be made when installing batteries?

- Inserting your radiator between the supply and return risers on any floor except the top one will make your riser neighbors freeze. The coolant will circulate through the small ring - through your battery, but the heat transfer of all devices above the improvised jumper will drop sharply.

- Radiator tie-in with any shut-off or throttling valves on the inlets without a jumper in front of the taps or throttles. In this case, a closed tap will stop the circulation in the entire riser.

- Lateral connection of a multi-section radiator, as already mentioned, will lead to a drop in heat transfer from the extreme sections.

- The connection of heating radiators with an undersized piping will also lead to a drop in thermal power relative to the nominal one. The norm is the pipe DN15 (1/2 inch) with up to seven sections and DN20 (3/4 inch) with more sections.

Material selection

The choice of pipes, batteries and fittings affects the efficiency and safety of the heating system at least as much as its scheme. What materials should be preferred in different cases?

Central heating

The nominal parameters of the central heating operation (4-6 kgf / cm2, 40-95 C) seem to allow the use of any modern pipes, batteries and fittings in it.

However, practice shows that it is better to refuse some of their types:

- The calculated value of the coolant temperature is often exceeded in severe frosts. With massive complaints about the cold in apartments, the operation of elevator units without a nozzle, with a muffled suction, is sometimes practiced. In this mode, the batteries can heat up to 130 - 140 C.

- Abrupt closing of any element of shutoff valves due to the incompetence of a locksmith or a breakdown will lead to a water hammer with a short-term increase in pressure up to 20-25 atmospheres.

Cast iron radiators are designed for a pressure of 9 - 15 atmospheres and can be destroyed during a water hammer.

It is the probability of emergency situations that leaves its mark on the choice of equipment for central heating.

Pipes

For installation of eyeliners can be used:

- Steel VGP (water and gas) pipe on welded joints;

- Threaded galvanized VGP pipe. Welds are contraindicated for its anti-corrosion coating: zinc burns out at high temperatures;

- Corrugated stainless steel pipe with compression fittings.

The latter option is attractive in that it is easy to assemble with your own hands using the simplest tool - a pair of adjustable wrenches. The price of a corrugated pipe with a diameter of 1/2 inch is about 200 rubles per linear meter.

Radiators

Central heating systems use:

- , representing a coil of pipe with fins that increase heat transfer;

- Bimetal radiators. The steel core makes them resistant to pressure surges up to 25 - 40 kgf / cm2;

- In rooms where aesthetics does not play a decisive role, the installation of home-made all-welded tubular radiators (registers) is practiced. As a rule, the connection of steel heating radiators is carried out with a black steel pipe on welded joints.

Heating system

Pipes

Fully controlled parameters of autonomous circuits allow the use of inexpensive and durable polypropylene and metal-plastic pipes in them.

A couple of subtleties are associated with their installation:

- For metal-plastic, not compression, but press fittings are preferred, which better tolerate numerous heating and cooling cycles;

- For polypropylene, reinforcement is desirable that reduces the elongation of pipes when heated.

Radiators

Everything is simple here: our choice is cheap, aesthetic and high heat dissipation aluminum batteries.

Aluminum sectional batteries are an excellent choice for a stand-alone circuit.

Valves and fittings

In recent years, American women have been massively used to connect the heater to taps and connections - fittings with a union nut, which make it possible to make the connection quick-connect.

The following can be used as control and shutoff valves:

- Ball Valves;

- Cone valves (chokes), allowing you to adjust the heat transfer in manual mode;

- Thermostatic valves with thermal heads allowing automatic maintenance of the set air temperature.

On the upper floors of apartment buildings and in cases where the upper radiator manifold is the upper point of a separate loop of the circuit, the radiator plug is equipped with a Mayevsky crane - a simple device for bleeding air plugs.

Conclusion

We hope that our review of connection diagrams and materials used in heating systems will help the reader make the right decision when planning their own repair or construction. The video in this article will offer him additional thematic information. Good luck!

Forces to solve a lot of issues, ranging from the choice of wiring diagram and ending with the selection of equipment. How to connect to ensure high-quality and uniform heating of all rooms? To do this, you need to consider the basic schemes for connecting heating radiators in a private house.

One-pipe and two-pipe schemes

The choice of the radiator connection scheme depends on the area of the heated premises, as well as on the piping system used. It can be one-pipe or two-pipe:

In a two-pipe heating system, unlike a single-pipe heating system, all radiators have the same temperature and evenly heat the house.

- In single-pipe systems, the coolant passes through the batteries in series;

- In two-pipe systems, the coolant is distributed among the batteries according to individual supplies.

Single-pipe systems are usually used in buildings of a small area. They are easy to install and extremely simple. The coolant leaving the heating boiler approaches the first battery, passes it and goes to the next battery. After passing through the last battery, the coolant is sent through a straight pipe back to the heating boiler.

The obvious advantage of the scheme is its simplicity - no need to make bends, spend money on extra pipes. Heating is cheap, although not always efficient. The thing is that the coolant, passing through the batteries and giving off heat to them, cools down. And it will reach the last battery already cooled down - it will be cool in the last room. This problem is solved by installing a circulation pump, which will make the coolant circulate faster.

Two-pipe systems are built so that each battery is connected by a separate pipe. A pipe with a hot coolant passes through all the rooms, taps are made from it to the batteries. After leaving the battery, the coolant is sent back to the boiler through another pipe. The advantage of this system is that all rooms will be heated evenly.- it will be warm even in the farthest room.

The disadvantage of two-pipe systems is their complexity - more pipes are needed, more labor costs. It is also necessary to provide a circulation pump, since natural circulation will not work here. In addition, users and specialists note a decrease in heating costs - two-pipe systems are more economical.

Connecting heating radiators in a private house through individual taps, using two-pipe wiring, will help to adjust the temperature in each room. This is not possible with single pipe systems.

Options for connecting heating radiators in a private house

We talked about the ways of laying pipes around the premises and found out that two-pipe systems are the most efficient, as they provide more uniform heating of the entire building. If the building is small, you can limit yourself to a single-pipe system - it will be cheaper. Now we will talk about how to connect heating radiators in a private house. There are the following schemes:

- Side scheme;

- Bottom diagram;

- Lower for two-pipe systems;

- Diagonal.

Let's look at how to connect heating radiators in a private house in more detail.

side scheme

The lateral connection scheme is often used in apartment buildings, when the coolant descends from top to bottom, passing through radiators in apartments. In order to partially compensate for the cooling of the coolant, a jumper connection is made. Radiators are also connected laterally in private houses, according to a two-pipe scheme - the coolant is supplied from above, after which it passes through the radiator and descends into the return pipe.

Sometimes a side scheme is called a one-way scheme - in fact, they are one and the same scheme. It is recommended for use when installing large-sized radiators for heating large areas.

Bottom diagram

Considering the connection diagrams for heating batteries in a private house, one cannot fail to mention the lower diagram. In it, the coolant is supplied at the bottom from one side and exits from the other side. The scheme is quite effective, but it is focused on single-pipe systems with series connection of radiators. In two-pipe systems, such a connection is practically not used. Often such a scheme for connecting radiators is called a saddle.

Lower for two-pipe systems

Some radiators are designed so that their inputs and outputs are located side by side (usually at the bottom). Such batteries are focused on use in two-pipe heating systems. The scheme is not without certain disadvantages associated with uneven heating. That is, the farthest part of the battery will be cooler than the rest of the surface. Therefore, the use of such radiators is not justified.

Diagonal pattern

The diagonal connection scheme is one of the most common. Its main advantage is the uniform distribution of the heated coolant throughout the battery. The coolant itself is supplied from the right upper part and removed through the lower left part (or vice versa). Due to the fact that it flows diagonally (and always from top to bottom), uniform heating of the entire battery is ensured.

This scheme is focused on use in two-pipe systems. In single-pipe systems, the presence of excess bends will cause an increase in hydraulic resistance.

Choosing the Right Schema

Which heating radiator connection scheme is suitable for certain cases? If you are creating a water or steam heating system in a small house, feel free to choose a single-pipe wiring with a bottom connection - other methods will not work here. Such heating systems are created in one-story one-room and two-room houses, as well as in small country houses.

If you need to organize a heating system in a large house, you should choose a two-pipe wiring diagram. To connect heating batteries, two schemes can be used at once:

- Lateral - when the heating pipes run from top to bottom and you need to connect only one battery;

- Diagonal - the recommended scheme for multi-room houses of a large area. In this case, the coolant will enter from the top of one side of the battery and exit from the bottom of the other side.

As for the lower scheme for two-pipe systems, it is only effective when the pipes are hidden in the floor. But even in this case, we recommend using a neat diagonal connection.