Septic tank with high GWL

The construction of a country house does not end with the construction of a box. Ahead is the most difficult and crucial stage - the construction of engineering communications. It is they who determine the comfort of living outside the city.

Perhaps one of the most important systems is drainage. In most suburban villages there is no central sewage system, which means that its construction is the concern of the owner of the house. It is especially difficult to organize a sewer network if the house is located on a site composed of quicksand or having a high level of groundwater.

Are you ready to give up the usual city comfort and want to live in a country house with "comfort in the yard"? Probably not. So it's time to choose equipment for the drainage system.

There are two possible options: a flow-through septic tank or autonomous local treatment facilities. At first glance, it may seem that both options have their advantages and disadvantages, and this would be true if we were talking about areas with normal GWL. With quicksand, everything is much more complicated. Let's look at all this in more detail.

The nuances of installing a septic tank in quicksand

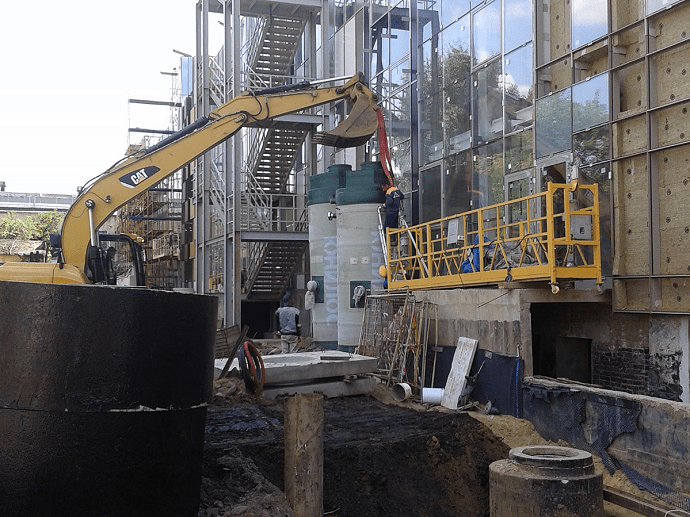

Installing a septic tank for a private house with a high level of groundwater in quicksand is incredibly difficult. Quicksand is a mixture of sand and water. It quickly erodes the walls of the pit, filling it. In clays and loams, installing a septic tank in a quicksand is easier, but not by much. In any case, such work is very labor-intensive.

Digging a pit for a septic tank in a quicksand is easier in winter, as the soil freezes through, does not float, and the level of groundwater and flood waters decreases. Despite this, there remains a risk that groundwater will not fall below the required depth.

In the summer, when groundwater reaches its maximum level, the installation of a septic tank in the country is necessarily carried out with the installation of formwork. This complex, time-consuming work is carried out in several stages:

- The pit for the installation of a septic tank is dug until water appears. The depth depends on the characteristics of the site.

- After the appearance of water, the assembly of the formwork begins. With high groundwater, formwork with a frame is required. The frame is assembled from a durable beam, on which guide boards are attached. Their choice is also not an easy task, because in case of an incorrect calculation, the soil pressure will simply crush the entire formwork.

- If there is a lot of water coming in, then it is necessary to additionally dig a drainage pit into which water will leave the pit. A drainage pump for dirty water is installed in the pit and groundwater is constantly pumped out.

- Formwork installation. After assembly, the frame is lowered to the current bottom of the pit and earthworks continue. As the depth is deepened, the frame is lowered and new boards are stuffed on top. Constant pumping and installation of boards occurs until the required depth is reached.

- A septic tank is lowered into the resulting pit. Regardless of the model of the septic tank, all installation work is carried out manually, without the use of special equipment. Immediately after installing the station in the pit and leveling it in level, it is necessary to fill all the chambers with water as quickly as possible.

- At the last stage, the development of a sewer trench takes place, this stage also complicates the fluidity of the soil, a pipeline is laid and the sewer pipe is connected to the station.

In practice, the installation of a septic tank at a high level of groundwater can be complicated by other factors, for example, the complex topography of the site or the special location of the station, the lack of the possibility of a quick intake of water or the impossibility of its rapid discharge, for example, into a storm drain, etc.

Having understood the nuances of installation at high groundwater, let's return to the question of choosing the right type of septic tank.

Flow septic tank

Simple 3-chamber septic tanks without aeration, sometimes with a submersible ruff bioload, such as Eurolos Eco. They are low cost, easy to install and operate. The model range allows you to choose the device of the desired performance. It would seem that flow septic tanks are the best choice in terms of cost. In practice, everything is different.

A flow septic tank cannot ensure the degree of wastewater treatment to sanitary standards, which means will require the arrangement of post-treatment systems- one or more drainage elements or a whole filtration field.

High groundwater is always a risk that some of the untreated sewage will fall into the ground and poison everything around. Therefore, in such conditions, it is impossible to install septic tanks with post-treatment of wastewater with soil.

And then a logical question arises: - “Then what is suitable?”

Local treatment facilities

These are biological wastewater treatment plants with gravity or forced discharge of treated water. Their distinctive feature is the treatment of wastewater right inside the septic tank, i.e. soil treatment is not required. After passing through all stages of treatment, wastewater meets the requirements of SanPin 2.1.5.980-00 "Hygienic requirements for the protection of surface waters".

Within the framework of a single house built on a site with a high GWL, this also means savings during operation. Treated wastewater is suitable for technical use, such as lawn irrigation. They can also be safely dumped into the ground, which means that the arrangement of post-treatment systems is not required. After analyzing these advantages, we get an almost ideal septic tank for a high level of groundwater - Eurolos Grunt.

What if it's a complicated installation?

Let's go back to the installation, if at the time of installation there is groundwater on your site, then additional efforts must be made to carry out the installation of a septic tank.

The production of formwork, various pits, the rental of a motor pump for pumping constantly arriving water, additional labor, and so on are superimposed.

In this case, it is easiest to bury the septic tank of the smallest size in height. Those. least depth.

It is for such cases as installation in quicksand, as well as for any other complex soils, such as rocky soil, that there is a specialized Eurolos Grunt station.

Price Eurolos Primer

| Production m 3 per day |

Dimensions and weight | Gravity station |

Enforcer- water discharge |

Standard mounting | |

|---|---|---|---|---|---|

| Eurolos GROUND 3 | 0.6 , for 2-4 people | 149kg 1.5x⌀ 1.2x 1.7m | 86000 rubles | 92000 rubles | rubles |

| Eurolos GROUND 4 | 0.8 , for 3-5 people | 162kg 2.0x⌀ 1.2x 1.7m | 91000 rubles | 99000 rubles | rubles |

| Eurolos GROUND 5 | 1 , for 4-6 people | 188kg 2.5x⌀ 1.2x 1.7m | 102200 rubles | 110200 rubles | rubles |

| Eurolos GROUND 6 | 1.3 , for 5-7 persons | 223kg 3.0x⌀ 1.2x 1.7m | 108000 rubles | 116000 rubles | rubles |

| Eurolos GROUND 8 | 1.6 , for 7-9 people | 267kg 4.0x⌀ 1.2x 1.7m | 119000 rubles | 131000 rubles | rubles |

| Eurolos GROUND 10 | 2 , for 9-11 people | 325kg 5.0x⌀ 1.2x 1.7m | 155000 rubles | 163000 rubles | rubles |

| Eurolos GROUND 12 | 2.4 , for 11-13 people | 359kg 6.0x⌀ 1.2x 1.7m | 167500 rubles | 175500 rubles | rubles |

| Eurolos GROUND 15 | 3 , for 13-17 people | 409kg 7.5x⌀ 1.2x 1.7m | 195000 rubles | 203000 rubles | rubles |

| Eurolos GROUND 20 | 4 , for 18-22 persons | 492kg 9.0x⌀ 1.2x 1.7m | 245000 rubles | 253000 rubles | rubles |

| Eurolos GROUND 25 | 5 , for 23-27 persons | 560kg 11.0x⌀ 1.2x 1.7m | 295000 rubles | 303000 rubles | rubles |

| Eurolos GROUND 30 | 6 , for 28-32 people | 636kg 13.5x⌀ 1.2x 1.7m | 370000 rubles | 378000 rubles | rubles |

The Eurolos Grunt aeration unit, with the lowest housing height on the market, requires a depth of only 1.5 meters from the ground, which greatly simplifies its installation.

A cylindrical body with large lugs, a minimum of external seams and seven internal chambers provide the strongest structure in the segment of on-site treatment plants, as well as installation that does not require anchoring or a concrete slab.

The close occurrence of groundwater is a factor that greatly complicates the installation of a septic tank on the territory of private country estates. Therefore, when planning the construction of engineering communications for a summer house or a house, it is necessary to take into account the "situation" on the ground. Ground water at the level of up to a meter is definitely a problem. A septic tank for high groundwater must be equipped in accordance with all the rules - otherwise the operation of the structure will be a complete headache.

How to determine the level of groundwater?

It is recommended to measure the groundwater level in spring, when the snow melts, or in autumn after prolonged rains. The distance between the surface of the earth and the “water surface” in the well, “feeding” on groundwater, is subject to measurement. No well? You can also determine the level of groundwater by drilling the soil with a garden drill in several places (for objectivity of observations). Well, the easiest method is to just talk to your neighbors and find out from them how things are in the area.

A high level of groundwater can be a problem when arranging a septic tank - but knowing the rules for carrying out work, many typical mistakes are easy to avoid

The problem of high GWL is typical for almost the entire territory of central Russia. Ground flows can occur even at a depth of 20-30 cm.

What is the insidiousness of the swampy area?

When arranging and during the operation of an autonomous sewage system in a site with a high level of groundwater, each homeowner may encounter such problems:

- The complexity of installation. What sweet speeches you would not have to hear from sellers of different types of structures, do not believe it - it will take a lot of time and effort to install a septic tank. However, having worked "at full capacity", there will be no doubt that the sewerage system with a septic tank will serve you faithfully, perhaps even for more than a dozen years.

- The emergence of a septic tank. If the septic tank is not installed on a concrete pad and secured with straps, nylon ropes or cables, there is a high probability that groundwater flows will provoke the septic tank to rise. As a result, the integrity of the structure of not only the septic tank itself, but also the entire sewer pipeline, has been violated.

- In a leaky septic tank, made, for example, of concrete rings, water will constantly leak. And this means that you will have to resort to the services of a sewage machine very often. Needless to say, it is very expensive?

- Complete flooding of the septic tank. The systematic flow of liquid into the septic tank will quickly render the structure unusable.

- Sewage seeping into the soil can become a source of groundwater pollution. Where it leads? It will take quite a bit of time and the water from the well will become unusable. Ponds adjacent to the site are at risk of blooming. There will be a local ecological catastrophe.

A septic tank installed on a site with a high level of groundwater must be completely sealed - otherwise you risk both your health and the contents of your wallet

Basic device rules for high GWL

The septic tank, if groundwater is close, must be completely sealed in order to prevent seepage of runoff into the soil. Structures, bricks and other prefabricated elements are not able to provide proper tightness - therefore, such options should disappear even at the stage of theoretical reflections on the sewage system. Ideally, it is desirable to resort to installing a septic tank of industrial production. On the market there is a wide range of these devices with different volumes. It is worth knowing that the volume of the septic tank should be equal to the three-day volume of water consumption by people living in the house.

Having studied, you will see that today you can easily purchase both a compact design for a small cottage and a multi-chamber installation designed for a modern cottage.

A three-chamber factory septic tank is a plastic container divided into chambers. The first chamber is a place for settling and dividing wastewater into fractions. The second and third are intended for post-treatment of wastewater. Instead of filtering wells, infiltrators are used in such structures - they provide rapid absorption into the soil of 94-98% of purified water. The main disadvantage of infiltrators is their large area. The industrial septic tank itself is, of course, quite expensive. However, such an investment is by no means an excess or a whim. A high-quality septic tank with high groundwater is a vital necessity.

With limited funds, you can build a septic tank yourself - from suitable plastic containers, for example, and design. Between themselves, the containers must be connected with special pipes for the flow of wastewater.

If industrial solutions do not suit you for one reason or another, you can always build a septic tank with your own hands

When equipping a septic tank in an area with a high GWL, it is necessary to provide a reinforced concrete pillow under the structure. By attaching the structure to such a base, it will be possible not to worry that it will be pushed out of the soil.

Also a good option for installing a septic tank with a high level of groundwater is the installation. Due to the absence of seams, the penetration of effluents into the ground will be impossible. The order of work will be as follows:

- digging a pit;

- formwork installation;

- fittings installation;

- pouring concrete.

It is advisable to pre-flavor the concrete mixture with a hydrophobic additive - this will improve the waterproofing properties of the future structure. Overflow holes must be provided in the partitions between the chambers. Inside, the finished chambers must be treated with coating waterproofing. If desired, such a septic tank can be built independently, without the involvement of specialists. It is enough to plan your work correctly and take into account all the nuances.

What other solutions are there to the problem?

If you have a small dacha that you visit two or three times a month, then the easiest and most cost-effective option for you would be to install a storage tank. It is desirable that it be made of fiberglass by machine winding. How would such a design work in practice? Drainage from housing will gradually accumulate in a sealed container, and then “extracted” by a sewage machine. For rare visits, a three-cube storage tank is more than enough for a whole season.

One of the most important components of the competent use of a septic tank is its high-quality, timely, professional cleaning - therefore, the services of a sewage machine should never be neglected!

As you can see, you can arrange a septic tank with a high GWL in many different ways. It is impossible to say which of them will be optimal for you in absentia. It all depends on your financial capabilities, the type of housing (permanent or temporary), the specific conditions of the area. After consulting with a competent specialist, we are sure that you will be able to make the right decision.

When soil waters lie at a depth of about a meter from the surface of the earth, this does not allow the placement of ordinary treatment facilities, but septic tanks are required for high groundwater. To determine the depth of occurrence, it is enough to check the site with a garden drill. It is desirable to do this in 3-4 places. After that, you will need to select the appropriate cleaning system.

When groundwater comes close to the surface, and sometimes its occurrence can be located even at a distance of 30 cm or less, many homeowners have no idea how to properly install treatment equipment on the site and what it should be like.

Design installation features:

- The septic tank must be mounted on a completely flat surface;

- It is considered mandatory to install the system on a concrete pad and securely fix it with cables, ropes or belts, otherwise it may float and be damaged;

- The body of the equipment must be firmly sealed, especially for devices made of concrete rings - this way water seepage can be avoided;

- Also, poor tightness of the installation can lead to the sinking of the model and contamination of soil water with waste sewage pipes.

Measurement of the high groundwater level should be done after spring floods or in autumn, when the rains end.

In the Middle Lane, the GWL problem applies to many territories and areas of the suburban sector, so you will need to choose high-quality equipment for cleaning sewers.

How to choose a country sewerage with a high level of groundwater

Of course, you can use home-made fixtures made of concrete, brick and other materials, but this approach is unlikely to ensure complete tightness of the structure.

This further threatens to cause serious problems associated with poisoning of groundwater with waste and flooding of the equipment case.

It is better to choose the optimal modification corresponding to the position. Special septic tanks are well adapted to the swampy area, designed to work with GWL.

You can solve this issue in the following way:

- For a summer residence or a private house, you can choose a small model of industrial production, the rating of such modifications is very high.

- You can design your own modification from eurocubes - special containers with a plastic container inside.

- Country sewerage in a territory with a high GWL necessarily provides for the installation of a heavy concrete pillow with iron elements under the septic tank. It is even better to make a concrete well without seams, which will provide protection against sewage from entering the ground.

The well will require digging a pit, installing formwork, reinforcement and pouring concrete.

Stages of construction: how to make a septic tank if groundwater is close

A high level of groundwater is not an obstacle to the construction of a sewer system.

With the independent construction of a treatment structure, the most important is:

- Absolute tightness of the case;

- For the strength and weight of the structure, it will be necessary to make a reinforced concrete pillow at the base;

- The freezing point of the soil must be taken into account.

Chambers for filtration and storage are made of metal or plastic cubes, concrete rings.

Work order:

- The location is determined - the sewer should be located 5 meters from the housing;

- A pit is being dug, the walls of which are reinforced with any wood material;

- A layer of waterproofing is placed at the bottom and a concrete solution is poured;

- After drying, another layer of waterproofing is laid, on which a septic tank is placed, while groundwater should be pumped out;

- Next, a ventilation pipe is assembled, which is necessary to remove methane;

- The structure must be buried;

- The cover of the equipment equipped with ventilation is erected.

The design will be reliable with maximum stability. This point needs special attention.

Advantages of a concrete septic tank with a high level of groundwater

Pat UGV often forces us to look for optimally acceptable solutions for the construction of an autonomous sewage system in a private house. Unlike materials such as metal, plastic, reinforced concrete rings for the body of a septic installation, cast-in-place concrete is more practical, since it allows you to build equipment of any size.

The main advantages of a concrete well are:

- The material is not subject to corrosion, rotting, calmly tolerates critical temperatures, is not afraid of small animals and insects;

- The seamless design is perfectly sealed and does not allow contaminants to penetrate into the groundwater;

- A concrete septic tank is the best because it is heavy, its ascent is excluded.

Concrete is the cheapest material, in connection with this, construction will not require large financial investments, which is also important.

Septic tanks for high groundwater (video)

In the countryside, especially if there is no central sewage system, the presence of aeration septic tanks is simply necessary. If a summer cottage or the territory of a private house is located in a swamp, this is not a reason to be upset. A home-made concrete septic tank or high-quality factory equipment for sewage treatment will help ensure that the home has a normal operation of an autonomous sewer system, and cleanliness, order and comfort will reign in the house for a long time.

Unable to connect to the central sewer? You can solve the problem locally - install a septic tank. To make this task easier, we have prepared a review of 9 reliable septic tank manufacturers. Chances are good that other companies you come across are either copying or counterfeiting these 9 products.

We warn you! Here and below, by septic tanks, we mean any engineering structures designed to collect or process wastewater, unless otherwise indicated. Including these are VOCs and SBOs - local treatment facilities and biological treatment plants, respectively.

Instructions for the selection and installation of VOC

Purpose of the article: tell about the most reliable companies that have been producing septic tanks and biological treatment plants for domestic wastewater for more than 10 years. Simplify the selection of a suitable equipment model based on the needs of the buyer, the soil conditions on the site and the budget of the purchase.

Types of septic tanks

Before we talk about wastewater treatment plants, let's conduct a small educational program. Conventionally, all treatment facilities can be divided into 3 groups:

- storage tanks. It doesn’t matter what they are made of, their function is the same - to accumulate drains in themselves before the arrival of a sewage truck. Relatively cheap, easy to install, no maintenance per se. Use is limited by the useful volume of the tank, hence the need for economical use of water and binding to the services of sewers. It's inconvenient and expensive. They are used only when soil and other conditions do not allow the installation of structures from the following two groups;

- settling tanks. Multi-section tanks that do not require electricity connection for sedimentation of wastewater and their anaerobic treatment. Microbiological purification processes proceed slowly in an environment depleted of oxygen. The outlet water has a characteristic odor and is purified by a maximum of 60%, so it must be cleaned up. For this, fields or filtration wells are used: effluents seep through the soil layer, after which they do not pose a threat to the environment. Settlers are simply arranged and affordable, but demanding to maintain. They periodically need to be cleaned of accumulated sediment, once every 5 years the filtration field must be redone. This solution is not suitable for high groundwater levels (GWL) and soil with poor throughput, such as clay;

- aeration stations. The most advanced systems for the preparation of households. drains. In the process of sedimentation, aeration and the use of microorganisms, wastewater is cleaned by more than 90%, has no smell, and can be drained into roadside ditches. However, such stations require connection to the mains, their efficiency suffers during power outages. Plus, they are expensive and require qualified maintenance.

We figured out the types of treatment facilities. It remains to take 5 steps to choose the right one for your operating conditions.

| Step 1. Choose your accommodation option | |

|---|---|

| seasonal (at the cottage) Operating conditions:

|

Ideal fit:

|

| permanent (in a private house) Operating conditions:

|

Ideal fit:

|

| Step 2. Choose the type of soil on the site | |

| clay Initial conditions:

|

Ideal fit:

|

| sand, sandy loam, loam Initial conditions:

|

Ideal fit:

|

| peat Initial conditions:

|

Ideal fit:

|

| Step 3. Choose the depth of groundwater | |

| above 1.5 Initial conditions:

|

Ideal fit:

|

| below 1.5 Initial conditions:

|

Ideal fit:

|

| Step 4. Choose a model according to the autonomy of work | |

non-volatile

|

Ideal for:

|

volatile

|

Ideal for:

|

| Step 5. Select the number of permanent residents | |

up to 5

|

Ideal fit:

|

to 10

|

Ideal fit:

|

up to 20

|

Ideal fit:

|

We hope that this table has helped you choose the right septic tank option. It remains to be determined by the manufacturer. The table below shows 9 companies and their brief characteristics. All the manufacturers we have reviewed offer solutions for both seasonal and permanent residence.

| Manufacturers of all types of septic tanks | ||

|---|---|---|

| , all types of septic tanks Bars |

Ideal for: residents of the above cities, because Bars is a practical and economical option for waste disposal. You can choose the most suitable model for the specific operating conditions of the septic tank. |

Middle price segment:

|

| , models Topas, TopBio, TopAero |

Ideal for: permanently residing in a private house, provided there are no power outages. |

Middle price segment:

|

| , models Cedar, Unilos Astra, etc. |

Ideal for: VOC devices in a residential home. |

Middle price segment:

|

| , Microbe, Tank, Biotank models |

Ideal for: a budget purchase for the country, which is facilitated by frequent manufacturer discounts and the simplicity of the design of most models. |

Budget price segment:

|

| , models Termite and Ergobox |

Ideal for: residents of the cities indicated above due to free delivery. For those who are looking for an alternative to Tank structures. |

Budget price segment:

|

| , Eurolos models |

Ideal for: those who need simple models of septic tanks for giving at a low price. |

Budget price segment:

|

| Manufacturers of non-volatile septic tanks | ||

| , Rostock models |

Ideal for: devices of inexpensive autonomous sewerage in the country. |

Budget price segment:

|

| Manufacturers of local treatment facilities | ||

| , models Eurobion, Yubas |

Ideal for: permanent residence, when the maximum degree of wastewater treatment is needed, even with significant salvo discharges. |

Premium price segment:

|

| , models Tver |

Ideal for: large areas with permanent residence, because the hatches provide free access to all parts of the installation and take up a lot of space. |

Middle price segment:

|

1. "Aqua Hold" - Bars septic tanks

at a price of 54,900 rubles.

2. "Topol-ECO" - treatment facilities Topas

at a price of 89,900 rubles.

"Topol-ECO" is engaged in the development and production of autonomous aeration-type treatment plants. The company was founded in 2002, the plant is located in the Moscow region, Lobnya.

The manufacturer's catalog includes both individual treatment facilities for private houses, as well as complex and specialized solutions - for a group of houses, villages and enterprises. Other plastic goods are also available: cellars, decorative stones, contact tanks, galvanizing baths, etc.

The company produces VOCs, which make up 3 large groups:

- For private houses. Topbio - non-volatile septic tanks for installation in sandy soils. Topas and Topas-S are stations with two or one compressor, respectively. Topaero - treatment facilities with protection against increased volley discharge of wastewater.

- For businesses and communities. Topglobal - a set of equipment with reinforced concrete tanks for cleaning households. and industrial waste. Topaero-M - a set of VOCs with increased total productivity for the treatment of domestic wastewater. Topaero-M / E - an analogue of the previous version for any type of wastewater.

- specialized stations. Toplos-FL - for cleaning wastewater from organic matter. Cyclone - a system for post-treatment of domestic wastewater. Toplos-KM - LOS container type for households. drains. Toppolium is a separator of fats from effluents from public catering establishments. Toprain - installation for the treatment of storm drains.

The presented equipment covers a wide range of performance. The youngest models are designed for 4 people, the oldest - up to 200. The use of active forced aeration guarantees 98% of domestic wastewater treatment. Therefore, the company positions its SBOs as treatment facilities that do not require the call of a sewage truck.

In most cases, polypropylene sheets with a thickness of 8 to 20 mm are used as the main material. The rigidity of the structure is achieved by using internal partitions and lattice structures as stiffeners.

| Model* | Topas 4 | Topbio | Topaero 3 |

|---|---|---|---|

| Operating conditions | For permanent use by a family of up to 4 people on a site with any groundwater level and type of soil. | For permanent or seasonal use by a family of 3-6 people on a site with sandy soil and low GWL. | Permanent use for a large family and guests - up to 15 people in total. Any ground conditions. |

| Short description | System with two compressors for aeration of drains and deep biological treatment. Effluent can be dumped into the ground or ditch. | Vertical 5-chamber non-volatile septic tank for which a filtration field is required. | Aeration system with the expectation of volley discharge of wastewater up to 1 m3. Effluent with up to 98% purification is odorless and can be dumped into a ditch. |

| Material | Polypropylene 12.5 mm for external walls, internal partitions 8 mm thick. | ||

| Size, L×W×H, mm | 950×970×2500 | 1600×1200×3000 | 2400×1200×2500 |

| Electricity consumption, W/h | 42-63 | — | 208 |

| Weight, kg | 215 | 400 | 605 |

| price, rub. | 89900 | 115900 | 218700 |

* you can choose a modification with a built-in pump for forced pumping of treated wastewater. Higher capacity models come with an extended neck for deep station installation when away from home, as well as heavy duty versions for difficult ground conditions.

Conclusion: the main part of the products from Topol-Eco, which can be used in a private house or in a summer cottage, are volatile biological treatment plants. They are made according to the most advanced technology to date, which is why they are more expensive than conventional septic tanks with a filtration field. But you also need to consider that such equipment requires qualified maintenance, does not tolerate a long power outage and is designed for continuous use.

3. "SBM-Group" - treatment facilities Unilos

at a price of 59,000 rubles.

The SBM-Group company produces Unilos stations, storm sewers, sewage pumping stations, plastic containers, fat separators. The plant has been operating since 2006 in the Moscow region, there is production in St. Petersburg, Novosibirsk, in 2015 a plant was opened in Kazakhstan.

Production technologies and assortment

The main emphasis is on autonomous sewage systems made of polypropylene, fiberglass and concrete. The stations are designed for household cleaning. and storm sewage. The performance of septic tanks, depending on the model chosen, can range from 0.6 to 10,000 cubic meters per day.

Septic tanks are represented by three product lines:

- Unilos biological treatment stations. This includes models of the Astra series and a modification with a service platform - Scarab, large-capacity systems for camps - Mega, container-type kits for rotational camps - Container.

- Septic tanks of low productivity for summer cottages. The line includes aeration stations of the Uni-Sep series of a hybrid type, a four-chamber non-volatile wastewater purifier Kedr and a three-chamber Unilos-OS.

- storage containers. Tanks made of polypropylene and reinforced fiberglass with sewage pumping by a sewage machine.

| Model | Unilos Astra 5* | Uni-Sep-1 | Cedar |

|---|---|---|---|

| Operating conditions | For a family of up to 5 people on a site with any soil conditions. | For permanent or seasonal residence of 5 people in conditions of periodic power outages. For any soil. | |

| Short description | Vertical station of deep biological treatment hoz.-byt. drains with gravity or forced drainage. The treated effluent is discharged into a ditch or soil. | Horizontal VOS with 2 maintenance hatches and 6 chambers for anaerobic and aerobic wastewater treatment. Discharge of purified water into a ditch or filter well. | Vertical non-volatile septic tank with 4 chambers for domestic wastewater treatment. Mandatory filter field device. |

| Material | Polypropylene. Side walls 15 mm thick, bottom - 20 mm. | Polypropylene 8 mm thick. | |

| Size, L×W×H or D×L, mm | 1030×1120×2000 | 1020×2000 | 1400×3000 |

| Electricity consumption, W/h | 60 | 71 | — |

| Weight, kg | 220 | 130 | 150 |

| price, rub. | 89500 | 72000 | 62400 |

*This is standard equipment. There are Midi modifications with a built-in SPS, a post-treatment and / or disinfection unit, as well as Long - with the same options, only of a greater height.

Unilos Astra 5 is the most popular model among those who live in a private house all year round. In the video below, they talk about the design of such a station and describe in detail the principle of its operation.

Conclusions: from the SBM-Group company under the Unilos brand, you can pick up the Astra aeration system, which is very similar in design to Topas from Topol-Eco. The choice among non-volatile septic tanks is limited to one model, but you can choose the storage capacity of the desired volume. Those. the manufacturer is more focused on consumers who permanently live in their own home.

4. "Elite Stroy Invest" - tank septic tanks

at a price of 34,900 rubles.

Elite Stroy Invest (formerly Triton Plastic) specializes in the production of plastic septic tanks, water and fuel tanks, caissons, swimming pools and a variety of products for summer cottages. The plant is located in the Moscow region, Mytishchi. Works since 2007. Delivery throughout the country through a dealer network is possible.

Production technologies and assortment

The catalog includes products for three types of drainage devices:

- storage containers. This includes containers made of polyethylene Triton-N with a volume of 1 to 3.5 m3;

- septic tank and. This includes the Microbe model (3-12 people) - a 2-chamber model for giving, as well as Triton-T (2-10 people), Tank and Tank Universal (1-25 people). These are 3-chamber tanks with the possibility of increasing the levels of wastewater treatment by adding additional blocks;

- bioremediation systems. Volatile VOC Biotank (4-10 people) and Eurobion (4-150 people) made of HDPE and polypropylene, respectively.

The main material for the manufacture of containers is HDPE. The thickness of the material is between 10 and 15 mm depending on the model and location. For example, it is larger for stiffeners, and less for straight lines or areas of small curvature.

The video below clearly demonstrates the production of models of the Tank line from HDPE. The plant is equipped with modern equipment, sheet plastic is supplied from Russian, Czech and German manufacturers.

| Model | Tank-2 | Microbe-450 | Biotank-3 itself* |

|---|---|---|---|

| Operating conditions | For a family of 3-4 people with permanent or seasonal use. Works at low GWL, soil - sand, sandy loam, loam. | Model for seasonal use. Operation by 1-3 people in economy mode. For low GWL and filter soil. | Seasonal accommodation for up to 5 people. Low GWL, sandy or loamy soil. |

| Short description | Cast horizontal 3-chamber sump with developed stiffening ribs. It can be completed with an infiltrator** (analogous to the filtration field). Mandatory soil post-treatment of wastewater. | Compact vertical septic tank with 2 chambers. Provides minimal cleaning from heavy and light fractions. It is necessary to arrange a filtration field. You can also purchase an infiltrator. | Vertical 4-chamber septic tank with aeration section. Installed 1 compressor and simple automation. The degree of wastewater treatment is 95-98%, after the station they can be dumped into a roadside ditch. |

| Material | HDPE 10-15 mm thick | HDPE 10 mm thick | |

| Size, L×W×H or D×L, mm | 1800×1200×1700 | 810×1430 | 1020×2120 |

| Electricity consumption, W/h | — | — | 60 |

| Weight, kg | 130 | 35 | 100 |

| price, rub. | 50500 | 16500 | 42500 |

* This is a model with gravity drainage of treated wastewater. There is a modification with an installed pump for forced withdrawal. There is also a horizontal model.

** The infiltrator looks like an inverted plastic bath; it serves as the boundary of the treated wastewater filtration area.

Conclusions: although this manufacturer has different types of models, it is known more for its sedimentation tanks. The Tank series line is ideal for suburban conditions and, in certain cases, can be used for permanent residence. In production, HDPE with a thickness of 10-15 mm is used, which is not always enough to ensure structural rigidity when installed in complex soils.

5. "Multplast" - septic tanks Termit

at a price of 25,000 rubles.

The Multplast company specializes in the production of polyethylene and fiberglass products: septic tanks, caissons, wells, etc. This manufacturer is known for its Termit and Ergobox product lines. The plant has been operating since 2004 and is located in the Vologda region, Cherepovets. The company has its own warehouses in Moscow, St. Petersburg, and also in the Krasnodar Territory. They deliver throughout the Russian Federation thanks to a developed dealer network.

Production technologies and assortment

The equipment is represented by 2 main product lines:

- settling tanks. Produced under the brand name Thermite. Includes several modifications: Profi - 2- and 3-chamber septic tanks for summer cottages with low GWL; Transformer - the same as the Pro, but with one neck (more rigid construction); Transformer PR - modification with a pump for forced pumping of treated wastewater at high GWL. There are also accumulative models with a capacity of up to 5.5 cubic meters;

- biological treatment plants. Produced under the Ergobox brand. They are modifications of the Transformer (PR) models in which a compressor and aerators are installed.

All these products are made by rotational molding of Korean-made HDPE. It turns out a strong seamless construction with developed stiffeners. The wall thickness is 20 mm.

| Model | Termite Profi 3.0 | Ergobox 6S* |

|---|---|---|

| Operating conditions | For a family of up to 6 people with a low GWL, when the soil is sand, sandy loam, loam. | For a family of up to 6 people with low GW, because it is a gravity version. The type of soil doesn't matter. |

| Short description | 3-chamber horizontal settling tank for primary treatment under anaerobic conditions. It is obligatory to arrange a filtration field for the post-treatment of wastewater. | 3-chamber LOS in horizontal execution with the Japanese compressor and the German pump. Discharge of treated effluents into a ditch, onto a relief, into the ground. |

| Material | HDPE 20 mm thick | |

| Size, L×W×H or D×L, mm | 2300×1155×1905 | 2000×1000×2100 |

| Electricity consumption, W/h | — | 63 |

| Weight, kg | 165 | 137 |

| price, rub. | 52100 | 73700 |

* S - gravity. There is a PR modification with a pump for forced pumping of treated wastewater. It costs 6 thousand rubles. more expensive than the gravity version.

Video demonstrating the process of installing a septic tank Termit. From a short video, you will also learn about the diameter of the supply pipe, whether it can have 90-degree turns, how and where to drain the treated wastewater, etc.

Conclusions: it is easy to notice the similarity of products from "Multplast" with products of the Tank type. All the same pronounced stiffeners and a simple design. Of particular interest may be versions with a compressor - a simple refinement gives the design special properties. However, it should be borne in mind that a small number of chambers can lead to a low quality of wastewater treatment and, as a result, the need for a field device or a filtration well for post-treatment.

6. "Eurolos" - cleaning systems Eurolos

at a price of 26,000 rubles.

The Evrolos company is relatively young, the plant has been operating in the Moscow region since 2015. It gained considerable popularity due to the release of high-quality plastic products: wastewater treatment systems, caissons, grease traps. Deliveries from the manufacturer are carried out from a warehouse in Moscow, throughout the country - through a developed dealer network.

Production technologies and assortment

Cleaning equipment is represented by 2 lines:

- for individual use. This is Eurolos Luck - a compact septic tank for seasonal use in the country; Eurolos Eco - 3-chamber sump; Eurolos Bio - VOC with pump and ejector; Eurolos Pro - aeration SBO. They are designed for a family of 3 to 20 people;

- for collective use. This is Eurolos Contus - a modular system for wastewater treatment. Productivity from 20 to 4000 cubic meters a day.

All containers are made of sheet polypropylene 8-10 mm thick. In the Biot model, oxygen is supplied not by a compressor, but by a combination of a pump + ejector. How it works is clearly shown in the video below.

We also recommend that you watch the full review of this cleaning station, which explains how the system works and the role of each of the nodes. We focus on the Bio model, because it is the most popular among Eurolos buyers.

| Model | Luck | Eco 1 | Bio 5 |

|---|---|---|---|

| Operating conditions | For a family of 2-3 people with seasonal living and economical use of water. GWL is low, the ground is sandy loam or sand. | For a family of 5 with permanent or seasonal use. GWL is low, good filtering ability of the soil. | For 5 people for permanent or seasonal residence. Any ground conditions. |

| Short description | Compact 2-chamber sump. Does not require digging a deep pit. A filtration field device is required. It is also recommended to use bacteria. | Horizontal 3-chamber settling tank with brush loading for cultivation of colonies of anaerobic bacteria. The arrangement of soil after-treatment is required. | Vertical VOC from 3 chambers and a biofilter with effluent circulation throughout the circuit. Aeration due to the ejector and fountaining. Does not require soil post-treatment - runoff can be dumped onto the terrain or into a ditch. |

| Material | Sheet polypropylene 8-10 mm thick | ||

| Size, L×W×H or D×L, mm | 1500×1500×800 | 1000×2000 | 1400×2000 |

| Electricity consumption, W/h | — | — | 88 |

| Weight, kg | 69 | 84 | 165 |

| price, rub. | 26000 | 43000 | 71000 |

The kit does not include related structures for arranging a system for discharging treated effluents. An infiltrator will cost an additional 5,600 rubles, a well - from 21,000 rubles, submersible drainage pumps - from 2,900 rubles.

Conclusions: in the assortment of the company "Evrolos" you will find solutions for the installation of a local treatment plant for seasonal and permanent residence of different productivity and degree of preparation of wastewater for discharge into the external environment. It should be noted the affordable cost of the basic set of equipment, however, due to the small thickness of the walls of the tanks, we do not recommend the installation of such systems in complex soils, where there is a possibility of squeezing the structure.

7. "Ecoprom" - septic tanks Rostock

at a price of 26,800 rubles.

Ecoprom has been producing goods from recycled polyethylene since 2008. The range includes water tanks, fuels and lubricants, septic tanks, grease traps, tanks for showers, etc. Today, there are 3 plants in the Moscow and Leningrad regions.

Production technologies and assortment

2 product lines are designed for local sewerage:

- drives. Sealed containers Rostok U with a volume of 1250 to 3000 liters.

- settling tanks. These are 2-chamber septic tanks Rostock Mini, Country, Country, Cottage. With a volume of 1000 to 3000 liters - this is enough for a family of 2-6 people.

All containers are made from recycled materials, which makes them competitively priced. Tanks are made of HDPE by rotational molding. In this case, the wall thickness is 10-12 mm.

Watch a 2-minute video that clearly shows the device of the Rostock Dachny septic tank and describes the role of each element of the cleaning system.

| Model | Rostock Country | Rostock Zagorodny | Rostock Cottage |

|---|---|---|---|

| Operating conditions | For 2-3 people. | For 4-5 people. | For 5-6 people. |

| Seasonal residence, low GWL, soil - sand, sandy loam. | |||

| Short description | 2-chamber horizontal settler with developed stiffening ribs. A filtration field device is required. Volley discharge and the use of aggressive chemicals are unacceptable. | ||

| Material | HDPE 10-12 mm thick | ||

| Size, L×W×H or D×L, mm | 1680×1115×1840 | 2220×1305×2000 | 2360×1440×2085 |

| Electricity consumption, W/h | — | — | — |

| Weight, kg | 85 | 125 | 160 |

| price, rub. | 33800 | 49800 | 58800 |

The price does not include an infiltrator for the filtration field device. This is about 7000 rubles. a piece.

Conclusion: Are you looking for the simplest settling tanks for giving and their main quality for you is strength, tightness and affordable cost? Then you should consider buying a septic tank from Ecoprom. Especially if we are talking about a summer residence, and the site is located somewhere on the outskirts of the partnership. Because the quality of pre-cleaning, due to the presence of only two chambers, leaves much to be desired.

8. "NEP-center" - Eurobion cleaning systems

at a price of 84,000 rubles.

Since 1998, NEP-Center Group of Companies has been specializing in the production of local treatment facilities for low-rise buildings. The plant is located in the Moscow region, Kubinka. The enterprise has a powerful scientific and technical base for developments in the field of wastewater and drinking water treatment. Delivery across the Russian Federation through a dealer network.

Production technologies and assortment

All systems are equipped with active aeration of wastewater and are allocated to a common group - aeroseptics. Depending on the model, they are able to meet the needs of 4 to 100 people. According to the engineer-inventor of the company, Yu. O. Bobylev, NEP-center products are the result of the evolution of the VOC Topas line.

| Model | Eurobion-5 ART | Yubas 5 |

|---|---|---|

| Operating conditions | VOC for permanent use by a family of 5 people. Any ground conditions. | |

| Short description | 4-section vertical installation with a large receiving chamber capable of enduring a salvo discharge of up to 390 liters. Differs in economical power consumption. Treated effluents can be dumped onto the terrain. | Vertical station with deeper cleaning. Able to take salvo discharge up to 700 liters. Consumes more electricity. It has a complex automation system, which complicates repairs. Drains after the system are dumped onto the terrain. |

| Material | Sheet polypropylene 10 mm thick | |

| Size, L×W×H or D×L, mm | 1080×1080×2380 | |

| Electricity consumption, W/h | 39 | 60 |

| Weight, kg | 125 | 270 |

| price, rub. | 85000 | 138000 |

Station maintenance is an important stage in the operation of the system. From the video below you will learn not only how to maintain the VOC Eurobion 5, but also how the station is cleaned and what role each of its components plays.

Conclusions: treatment facilities from NEP-Center have a well-thought-out design in terms of wastewater treatment efficiency, but their maintenance requires highly qualified workers. Such systems are great for continuous operation, but at the same time their cost is higher than analogues.

9. TD "Engineering equipment" - septic tanks Tver

at a price of 67,900 rubles.

The company Trading House "Engineering Equipment" has been operating since 1992 and specializes in scientific research, production, construction and installation of equipment for wastewater treatment and pumping. In the assortment of the company LOS Tver, facilities for the treatment of stormwater Svir, grease traps, wastewater treatment plants for car washes, regions of the North. Production is carried out at 4 factories in the Russian Federation.

Production technologies and assortment

- for private houses. Biological treatment stations made of polypropylene of the Tver-P line are designed for 2-36 users, depending on the performance of the system;

- for residential complexes. Cleaning equipment in a metal or polymer case of high capacity for 30-1500 people.

- for shift camps. Container version Tver-S for 6-1000 people;

- in block-modular design. Modular designs Tver-BM with flexible adjustment of wastewater flow by varying the number of connected units;

- for landfills. Specialized Tver-MSW stations in container design for deep wastewater treatment of MSW landfills.

All models of treatment systems Tver are volatile installations for seasonal or permanent residence. Polypropylene 5 mm thick is used as the material for the walls of the containers. Rigidity of a design is provided with stiffening ribs and internal partitions.

* There are 7 more modifications of this station, for example, the model with the PN index has a pump compartment with a submersible pump for forced supply of treated wastewater.

The video below provides detailed information on the installation of a septic tank Tver-0.75 PN. A company representative at a real facility explains the structure of the system and the role of each of its elements. The maintenance of the station is described in detail. If you're thinking about buying this model, be sure to check it out!

Conclusions: Trade House "Engineering Equipment" does not offer a wide range of systems for country houses. The guys just designed a model that works well and scaled it up. It turned out not the most compact water purification station at an average price. The main thing is that it works, right?

Editor's Choice

All the presented manufacturers are good, but we especially want to highlight the following:

- Aqua Hold. For septic tanks Leopard: a large selection of models of different types, the durable case of which is made of HDPE 25 mm thick. You can choose a treatment plant for any conditions. There are solutions for giving, for permanent residence, for low and high groundwater levels, various types of soil. Prices for products are average for the market.

- Elite Stroy Invest. For simple septic tanks Tank, which are ideal for giving - durable, reliable, at a price of 25,000 rubles.

- TD "Engineering Equipment". For biological treatment plants Tver. Unlike most VOCs, it not only copes with the task of treating wastewater, but is also easy to maintain - no need to call a specialist. This is possible due to easy access to each chamber of the station.

Frequently asked Questions

Here we have collected answers to current questions about septic tanks.

What material is the best septic tank?

Factory products for individual use are made of polymeric materials: polypropylene, low-pressure polyethylene (HDPE), fiberglass. They are relatively light, not subject to corrosion, strong, sealed and durable - all these materials are good.

The only question is to what extent their capabilities are implemented in a particular septic tank design. For example, there may be a container made of polypropylene, in which the seams are poorly welded, respectively, after some time it will leak.

The rigidity of the structure is influenced by the thickness of the material and the presence of structural elements: stiffeners and internal partitions. Therefore, if the design is unsuccessful or simply does not fit the specific operating conditions, the septic tank can be flattened or torn apart by soil. But the point here is not in the quality of the material from which it is made, but in the design itself.

I can not decide between a non-volatile septic tank and a biological treatment plant with aerators. What's better?

If for a summer residence, choose a non-volatile sump, provided that the groundwater level is below 1.5 meters, and the soil itself has good filtering abilities. For example, it is sand or sandy loam. Once a season, you will have to do dirty work and remove accumulated sludge from the bottom of the tank, but in general, this solution is the most cost-effective and convenient for seasonal living.

For private houses, it is better to buy a system that provides maximum cleanliness of wastewater at the outlet of the treatment plant. Here you can not do without a station with aerators. Of the benefits: the drains after it do not smell, they are cleaned so much that they can be drained into roadside ditches. However, this solution is more expensive, and automation and compressors require connection to the mains.

Summer cottage next to the forest, seasonal accommodation, four people. Recommend a septic.

If you need cheaper and easier, then consider the Termit Profi 2.0 option. It is very similar to the well-known Tank, but it costs only 39,000 rubles. Also, the manufacturer often has promotions - you can save several thousand.

The filtration field can be arranged next to the forest. There you will dump wastewater for further treatment. So you deliver a minimum of inconvenience to yourself and your neighbors.

There is a well at the dacha, from where water is used for food purposes. Which septic tank to choose?

Obviously, a treatment station is required here, after which sewage can be dumped into a roadside ditch. If there is no ditch, it can be lowered into the ground, provided that the discharge point should be 50 m from the well.

If the soil does not accept water, then in some cases it makes sense to think about installing a storage tank with the subsequent call of sewers.

Will drains freeze in winter? Do I need to insulate a septic tank?

If they are used constantly, they will definitely not freeze - a kind of bioreactor is constantly working inside, releasing heat. In extreme cases, you can insulate by pouring a layer of straw or leaves on top.

During seasonal operation, it is recommended to fill the tank by 2/3 with drains, additionally insulating from above. So the container will not float and will not be crushed by frozen soil. We recommend that you additionally read the instructions for a specific model, the manufacturer may have a different opinion on this matter.

What will happen to the volatile water treatment plant if the electricity goes out?

Typically, such systems are very sensitive to power outages. The compressor that pumps air stops working, and after 6 hours the amount of oxygen in the drains is significantly reduced. A struggle begins between aerobes and anaerobes. Drainage can begin to ferment due to anaerobes, so after turning on the electricity, normal operation occurs within a few days.

Is there a strong odor from the septic tank?

After a conventional sump, a strong characteristic sewer smell. It can be felt even near the filtration field, so they are equipped in the most remote place.

After systems with aeration, the water is cleaner and does not smell. Unless the operating mode of the station is violated: exceeding the permissible peak discharge, power outages, the use of aggressive detergents.

Installed a septic tank with a filtration field without connecting to the power supply. How to serve it?

Once every six months, it is necessary to open the container and check the amount of sediment. If it is more than 1/5 of the height of the container, you will have to remove it. Use a bucket or a fecal pump for this purpose.

Light fractions will accumulate on the surface of the effluents. If they form a thick hard layer more than 5 cm thick, it is also better to remove it in a timely manner, because later it can significantly complicate the cleaning of the tank.

The arrangement of sewage and treatment facilities in a summer cottage or personal plot requires taking into account many small things and nuances that at first glance seem insignificant. An example of such a factor is the groundwater level (or GWL for short) in the area where a private house or cottage is located. If they lie deep, then everything is fine, one less problem. But not all sites are in such favorable conditions - in some GWL is 0.5-1 m. In this case, when installing a treatment plant, it is necessary to solve a whole range of problems, and the design of a septic tank for a high level of groundwater has its own characteristics, differences. And every owner of a summer house or a cottage should know about it.

The problem of high groundwater for sewerage

Let's start with what problems and difficulties for the sewerage system create groundwater, which lies only 0.5-1 m from ground level.

- Flooding- due to heaving of the soil and the movement of groundwater, there is always a risk of moisture penetrating from the ground into the septic tank. This problem is especially acute for composite structures made of concrete rings, whose tightness leaves much to be desired. As a result, the tanks quickly overflow with liquid, it becomes necessary to call a sewage truck. And in the worst cases, groundwater flows mixed with fecal masses will flow from the septic tank into the sewer, and then into the house, flooding the bath and toilet.

- Ascent- this problem is typical for lightweight structures made of plastic cubes. In the spring or after heavy rains for many days, the soil is saturated with a huge amount of water, which puts pressure on it, trying to squeeze it up. In this case, the septic tank itself turns into a kind of "float". And if the tanks were not securely fixed to the concrete pad, they would start to float up. Often this phenomenon is accompanied by a roll, leakage and sewer breaks. As a result, a cleaning system that has become unusable, part of the site is flooded and fecal matter penetrates into groundwater.

- Drainage- one of the most important stages of sewage treatment is soil post-treatment. Water, passing through the septic tanks, enters special filtration fields. There, it seeps through a bed of gravel into the soil, where it undergoes the last and most important stage of purification. According to sanitary standards, between the GWL and the filtration field there must be a layer of earth with a thickness of at least a meter. Accordingly, it is rather problematic to fulfill this requirement with groundwater lying at 0.5-1 m. Ignoring these norms leads to pollution of the surrounding ponds, rivers and wells.

- swamping- the soil in the zone with high GWL is characterized by high humidity. Therefore, the ability to absorb water for post-treatment will be worse. And if this factor is not taken into account, then the land around the septic tank will turn into a small swamp.

- Septic tank damage- groundwater is often characterized by increased alkalinity or, conversely, acidity. In such cases, they not only put pressure on the walls of the tanks and penetrate in case of leaks, but also gradually destroy them. This is especially true for concrete structures. In addition, groundwater is not static, it is in motion and often carries with it small and sharp stones, which can also damage the integrity of septic tanks or communication pipes.

- Installation problems- one of the main problems for the arrangement of treatment facilities in areas with high GWL. When digging a pit, builders will be forced to work knee-deep in water. In addition, the process of pouring concrete or installing industrial septic tanks becomes more complicated.

Important! The danger of seepage of sewage into the ground, mentioned several times above, is that groundwater is constantly moving and mixing. And if fecal masses, sewage and harmful microorganisms got into them somewhere, then they spread over a large area. As a result, soil and groundwater become polluted, and nearby wells, streams, and ponds become poisoned and undrinkable. In fact, a local environmental disaster occurs, which was caused by errors in other treatment systems.

Determine the depth of groundwater

You know about the problems that appear with a high GWL. The next step is to determine the depth of groundwater in your own area.

The list contains three ways to do this, listed in order of increasing difficulty:

- polling neighbors;

- search for indicator plants;

- drilling of exploratory wells.

The second way is to evaluate what grows on your site and in the surrounding area. Plants are a kind of indicators that allow us to draw approximate conclusions about the level of groundwater. If the flora on the site is predominantly moisture-loving, then, most likely, the GWL is high here. For a more precise definition, use the table.

Table. Indicator plants that indicate the level of groundwater in the area.

| Approximate groundwater level, m | indicator plants |

|---|---|

| 0 to 0.5 | Sedge, cattail, reed, Langsdorf reed grass, wild rosemary, fluffy birch |

| 0.5 to 1 | Canary grass, meadowsweet, cattail, reed, |

| 1 to 1.5 | Sand bulrush, spruce, heather, blackberry, mouse pea, white bent grass, meadow grass and fescue |

| From 1.5 and deeper | Yellow alfalfa, naked licorice, chiy, meadow clover, awnless bonfire, plantain, creeping wheatgrass, juniper, moss, lingonberry |

The third method is the most accurate, but at the same time the most time-consuming. We will present it in the form of a step-by-step instruction.

Step 1. Prepare a drill with a length of at least 2 m. If necessary, you can use a tool with a greater drilling depth.

Step 2 Identify several locations on the site for wells. It is desirable that one of them is located where it is planned to install a septic tank and treatment systems.

Step 3 Drill a hole 2 m or more deep.

Step 4 Wait a day. For reliability, cover the wells from above with waterproof material so that night rain does not interfere with the determination of GWL.

Step 5 Prepare a metal pin or wooden stick under the depth of the well. Put marks on its lower part every 10 cm.

Step 6 Immerse this "indicator" in the well and pull it out. Determine how long the pin turned out to be wet and determine the GWL. As an example: a well was dug 2 m deep, the pin turned out to be 30 cm wet. Perform simple calculations 200 – 30 = 170 , therefore, the groundwater level in this place is 1.7 m.

Step 7 Wipe off the "indicator" or let it dry and repeat the experiment with other wells in the area.

Step 8 Repeat steps 6 and 7 with all wells for three days to get more or less accurate results.

Important! It is best to take measurements in the spring, after the snow melts, when groundwater rises to a maximum. If March or April is too long to wait, experiment in summer or autumn after a few days of heavy rainfall.

What should be a septic tank for a high level of groundwater

Consider the basic requirements that each must meet, placed on a site with a high level of groundwater.

Video - Construction of a septic tank on a site with a high level of groundwater

Monolithic concrete septic tank - instructions

One of the most common designs created independently for a country house or cottage. The walls and bottom of the septic tanks are reinforced with a grate and have sufficient strength so as not to collapse under the pressure of groundwater and earth from the outside. Due to heavy weight, it cannot emerge in the spring or in the rainy season. In this case, step-by-step instructions will be considered for creating a three-chamber monolithic concrete septic tank, which provides a significant degree of sewage treatment.

Step 1. Determine the place under), its dimensions, then proceed to dig the pit. Depth - 3-3.5 meters. If possible, order the work of an excavator or a team of excavators - in this case, you can dig a pit on the first day. To prevent shedding of the walls, lay them out with plastic wrap. Tamp the bottom of the pit.

Important! Additionally, it makes sense to build an awning over the foundation pit so that it is not flooded with rain. In order to minimize the problem with groundwater, proceed with the arrangement of the septic tank in the summer during the driest period. If moisture still accumulates at the bottom of the pit and interferes with work, bring the hose from the pump there.

Step 2 Lay a compacted and moistened sand cushion at the bottom with a depth of 15-25 cm.

Step 3 Proceed to the construction of the outer formwork. Use at the same time thick enough and strong boards, as a large mass of concrete will be poured. If the formwork is too weak, he can simply spread it to the sides, especially in the lower part of the monolithic septic tank. Do not forget about the spacers from the timber.

Step 4 Begin to form a reinforcing lattice at the bottom and walls of the pit. Use steel bars with a cross section of 10 mm, tie them together with wire. The side of each individual lattice cell is from 20 to 30 cm.

Step 5 Form a reinforcing lattice on the partitions that will divide the septic tank into separate chambers.

Step 6 Fill the bottom of the pit with concrete, the thickness of the bottom of the septic tank should be at least 150 mm. Add anti-corrosion and waterproofing additives to the mixture so that the tank does not leak groundwater and is not subject to destruction due to the aggressive internal and external environment.

Step 7 Build an internal formwork that will form the walls of the septic tank and divide it into three separate chambers.

Step 8 Proceed to pouring the outer walls and partitions of the septic tank. Don't forget about forming overflow holes from chamber to chamber. When pouring, try to reduce the number of cold joints, as they will be the weak points of the structure, in which leaks will occur first.

Step 9 Build the formwork for the roof of the septic tank. In this case, the boards must be carefully adjusted to each other. Do not forget about hatches and ventilation - each chamber of the septic tank should have its own hatch for inspection, maintenance and, if necessary, sewage.

Step 10 Fill with concrete the ceiling, which will be the roof of the future treatment plant.

Step 11 Separately, form a reinforced grid around the hatches and fill them with cement mortar.

Step 12 Inside, mount the tees of the overflow holes, fill the septic tank with soil on top, install the manhole covers and the ventilation system.

A three-chamber monolithic concrete septic tank is ready. Then you just have to make a diversion from it to an embankment with a filtration field (for post-treatment of technical water) or to a sewer.

According to a similar principle, a two- or three-chamber septic tank from European cubes is equipped. In this case, it is necessary to take into account the high level of groundwater and, accordingly, the risk of ascent. Therefore, plastic eurocubes are mounted on an anchor concrete slab previously poured or laid in a pit. It also makes sense to protect the structure from the sides with something from squeezing during heaving of the soil.

When using an industrial septic tank, such as or, the same recommendations are valid - a concrete slab is installed at the bottom of the pit under the treatment plant, the tank itself is fixed on it with anchor straps, as in the image below.

If you consider yourself not too well versed in construction and are in doubt, then it is better to contact an experienced specialist who has encountered similar problems and knows the solution when installing both a home-made and an industrial septic tank. Remember one important truth: when improving a site, money is spent either at the construction stage or after it, but already on correcting mistakes and dealing with the consequences of savings at the expense of reliability.

Prices for anti-corrosion and waterproofing additives

anti-corrosion and waterproofing additives