Even if the production of furniture is far from your field, making a country table with your own hands to get together with family and friends on warm summer evenings is quite a feasible task.

Its main advantage, in contrast to the purchased one, is its undoubted economy. It is not necessary to make a table from scratch: simply by assembling the purchased parts, you will save 30-50% of the cost. If it is possible to use the materials left over from construction or repair, the costs will be limited to the purchase of accessories.

To select a design, you need to decide where the product will be used.

Using cheap off-grade boards - substandard - for a country or kitchen table, you will receive advantages that are not available for mass production. Sounds dubious? But this is so: the knots, due to which the boards are rejected, have very interesting decorative properties. If you succeed in highlighting them, you will become the author of a completely unique design product, which is a pity to leave in the garden in the rain.

Making a country table with your own hands to get together with family and friends on warm summer evenings is quite a feasible task.

To choose a design, you need to decide where the product will be used: on a grassy lawn under a tree, complement the gazebo, stand in a workshop or in a house.

The simplest country table can be mounted in a few hours with a minimum of materials, but it will not last long either. To get a product that will be really pleasant to use, you need to carefully prepare the boards and perform all technical operations with high quality at each stage.

Its main advantage, in contrast to the purchased one, is its undoubted economy.

If you find a large tree stump in the forest, it can make an easy-to-make garden table. You just need to remove the bark from the stump, make an even cut along the top, grind it, treat it with an antiseptic and varnish it. It is enough to nail or screw the finished furniture board to the "leg" from the stump - and you're done.

Tabletops made of boards, fastened at the bottom with transverse slats, look good. If you prefer a glued countertop, you can do it yourself, but it will take a lot of effort.

If you succeed in highlighting them, you will become the author of a completely unique design product, which is a pity to leave in the garden in the rain.

It is difficult for a novice craftsman to fix the legs securely, so try to choose a design, correctly assessing your skills and taking into account the cost of labor and time. The easiest way to make cruciform and L-shaped legs. To attach straight legs - you need to carefully connect the parts.

One of the most comfortable options for a garden is a collapsible table with benches that can be installed in a gazebo or on a veranda. It is not difficult to carry out it, the main thing is to choose high-quality materials and properly prepare them for work.

The simplest country table can be mounted in a few hours with a minimum of materials, but it will not last long either.

How to choose a tree?

For a garden or kitchen table, wood of many species is suitable, both soft (pine, spruce, cedar, fir) and hard (oak, birch, ash, walnut, maple, apple, pear, acacia, etc.) The exception is too soft species wood (poplar, alder, aspen, willow).

One of the main parameters of the suitability of wood for the manufacture of furniture is resistance to decay: the species listed above meet this requirement.

If you do not plan to do furniture work all the time or are just starting to practice, give preference to the most common types of wood - pine and birch.

Tabletops made of boards, fastened at the bottom with transverse slats, look good.

Various wood species can be used for the table top, frame and legs. At the assembly stage, dowels will be needed: they are usually made from acacia or boxwood. Birch wood has an inexpressive pattern and can warp significantly due to spilled liquid - it is better not to use it as a tabletop material, but thanks to the hardness of this breed, legs can be made from it.

The countertop is best made of oak or pine. If you know how to brush wood, the surface of the kitchen table can be a real work of art. Wood of soft types lends itself to brushing: the wood is burned with a gas burner, and soft fibers are removed with an iron brush. It is better to carry out work in the yard due to the large amount of dust. If you managed to burn the wood evenly, the result will delight you. Brush can be tinted with stains, stains, diluted with water, artistic acrylic paint. Of course, wood brushing is not necessary: this is only a finishing option.

If you prefer a glued countertop, you can do it yourself, but it will take a lot of effort.

Selection of paints and varnishes and adhesives

Before proceeding with the installation, the boards must be protected from decay. The tree needs to be impregnated with a water-polymer emulsion (WPE): processing is carried out twice with an interval of 3-5 days. This is enough for the product to serve for a long time.

Some models require glue. Along with special carpentry adhesives (BF-2, etc.), you can use construction PVA: it is applied to both glued surfaces, dried until tack-free, then the parts are connected and kept under pressure for up to three days.

It is difficult for a novice craftsman to fix the legs securely, so try to choose a design, correctly assessing your skills and taking into account the cost of labor and time.

The choice of paints and varnishes is determined by where the product is planned to be used: in the yard or indoors. For a garden table that is inevitably exposed to precipitation, alkyd, alkyd-urethane, nitrocellulose varnishes and oil paints are suitable. For the kitchen table, as well as for any furniture that is constantly in the room, it is better to use acrylic paints and varnishes: they are more environmentally friendly, do not have a strong smell. Varnishes marked with the blue angel are recommended for children's furniture and toys.

If you decide to cover the wood with wood stain, paint or just tinted varnish, this must be done before assembly. Consideration must be given to material compatibility. The varnish is tinted with a paint suitable for its composition: if the varnish is alkyd, the paint should be oily, if you use acrylic varnish, it can only be tinted with acrylic paint. First, a small amount of varnish is thoroughly mixed in a separate container with paint, and then the resulting mixture is added to a larger varnish.

One of the most comfortable options for a garden is a collapsible table with benches that can be installed in a gazebo or on a veranda.

What tools are needed

For work you will need:

- hacksaw,

- circular saw or jigsaw;

- drill;

- screwdriver;

- hammer (if it is decided to use nails).

Many species of wood are suitable for a garden or kitchen table.

This list includes only the most necessary tools, but to make the work more comfortable, and the finished product looks aesthetically pleasing, it is advisable to buy or rent a rotary miter box, an eccentric grinder and a milling machine.

The swivel miter box makes it possible to make cuts at exactly the right angle. The eccentric sander allows you to prepare parts simply, quickly and efficiently: you will sand the boards in an hour, instead of doing it all day by hand with sandpaper. For high-quality processing of the ends, a belt sander is useful, and a milling machine allows you to select the wood for the necessary grooves and process the edges.

If you do not plan to do furniture work all the time or are just starting to practice.

Homemade pallet table

A spectacular, rustic-style table can be constructed from pallets (wooden pallets). If you are the lucky owner of such a container, especially a double-deck pallet, just disassemble it: there is no problem of purchasing boards!

Do you think buying new boards is always better? You probably have not worked with wood before: you cannot use raw wood (the product deforms after a few months), and dry boards are much more expensive. To dry raw wood boards, stack them in a well-ventilated area: this necessary process will delay your project by 4-6 months! A good option for the kitchen table can be the already mentioned rejected boards, also dry.

Various wood species can be used for the table top, frame and legs.

Let's go back to the pallets: they are disassembled. Now you have at your disposal sturdy boards with different patterns and colors, it is possible that from trees of different species. These features should not be considered as disadvantages: they will give the product a zest: you just need to create an interesting composition of them, alternating boards of a similar shade.

The sides of the pallet will make an excellent frame, and the remaining planks will be used to assemble the countertop.

It is better to carry out work in the yard due to the large amount of dust.

To make the legs, you will need a bar with a thickness of at least 5 cm.All details must be prepared: sandpaper strictly along the fibers with coarse sandpaper (No. 120-150), then with a finer grain (No. 400-600), carefully removing dust.

Some boards can be painted with acrylic or oil paint. Fans of the loft style can use stencils in the form of numbers or simple graphic symbols. Boards with a beautiful natural pattern are “stained” or simply varnished. After staining or the first layer of acrylic varnish, the soft fibers rise; sand them with medium-grit sandpaper and apply a new coat of varnish.

A spectacular, rustic-style table can be constructed from pallets (wooden pallets).

If a non-aqueous varnish is used, it is enough to apply 2-3 coats, and if acrylic, the number of coats can be up to ten.

Rejected boards, also dry, can be a good option for the kitchen table.

We fasten the tabletop boards with planks, which we place at the joints of the boards. Using a drill, a screwdriver and self-tapping screws, we fasten the boards to the slats (at the joints we use two self-tapping screws, on solid boards - one). The use of a drill is necessary so that the wood does not crack when screwing in the screws. We assemble the frame from the prepared pallet sides. Using a drill of a suitable diameter for self-tapping screws, we drill holes at the joints. We coat the joints with glue and fix with self-tapping screws. Install the legs: just screw the boards to the frame, screwing in the screws diagonally. To strengthen the structure, we make the lintels at the bottom in a similar way.

To make the legs, you need a bar with a thickness of at least 5 cm.

Wooden table with glued top

For glued worktops, you need to choose boards of the same width. If the table is intended for a workshop and its appearance does not really matter, you can use old floorboards: there are already grooves there. To make the grooves yourself, you need a milling machine.

A flat surface is required to collect the countertop. We just coat the sidewalls with glue, join the boards without gaps and tighten the resulting structure with clamps. Depending on the glue used, the worktop should dry from 1 to 3 days. If everything is done correctly, you will get a worktop with a completely flat surface with no gaps. It remains to work out the ends - first trim with a jigsaw, and then grind. In the absence of a belt sander, this must be done manually - with sandpaper, first coarse, then medium grit.

After varnishing the parts, you can proceed to the installation, which consists of several stages.

If you don't want to mess around with glue and clamps, you can use a ready-made furniture board from a hardware store. Then it remains to cover the tabletop with a transparent or tinted varnish.

For a good result, you need to apply 5-7 (for acrylic varnish up to 10) layers. After every third layer, the working surface of the countertop must be sanded with fine-grained emery paper, carefully removing the dust with a damp cloth. At the stage of varnishing, it is important not to rush: each layer of varnish should dry well.

It remains to make the legs of the garden or kitchen table: let's dwell on the version with L-shaped legs. You will need boards with a thickness of at least 22-25 mm.

For glued worktops, you need to choose boards of the same width.

L-shaped legs consist of two parts, connected at an angle of 90. On the boards to be connected, it is necessary to make a sample, coat the joint with wood glue, and then install self-tapping screws.

When the glue dries, cover the legs with varnish and, after drying, simply attach them to the countertop with screws.

There are several options for connecting the legs to the table top.

Table with straight legs

To make straight legs, it is enough to saw a thick bar into pieces of the same length. There are several options for connecting such legs to the table top.

To ensure that the straight legs are installed securely, you can use a dowel joint at home. You can make them yourself from acacia wood or buy ready-made ones. To assemble the dowel joints, you need fast-drying wood glue (BF-2).

To make straight legs, it is enough to saw a thick bar into pieces of the same length.

Table with X-shaped legs

Sequence of work.

- On the inner side of the tabletop, we fasten two strips on each side with self-tapping screws.

- To make the table look good, the edges of the planks must first be cut at an angle of 52.

- We fasten the paired strips so that the legs fit, we make gaps of 2-3 mm on each side.

- We put the boards on a flat surface, crossing them at the desired angle. We measure the distance between the ends of the boards: it should correspond to the width of the table.

- We outline the intersection with chalk: here you need to choose half the thickness of the boards so that after assembly they lie in the same plane.

- We coat the grooves with glue and place the parts under the press for 1-3 days. For greater reliability, the connection can be strengthened with self-tapping screws.

- We varnish the legs.

- It remains to attach them to the tabletop, placing them in the grooves formed by the slats - and the table for giving with your own hands is ready.

X-shaped legs are made of beams or boards with a thickness of at least 50 mm.

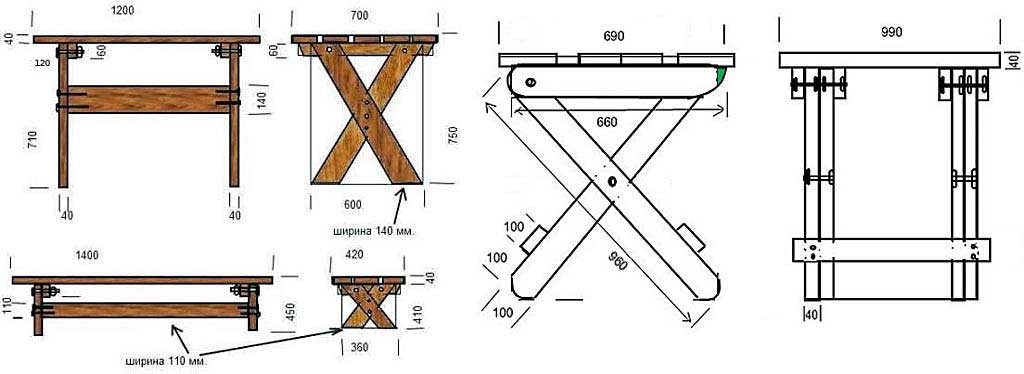

Table with benches

The optimal solution for a gazebo is a dining table with benches attached to it. It is better to make such a structure collapsible in order to clean it up for the winter indoors.

For the table, you will need thick boards (from 32 mm), which must be cut into pieces according to the drawing. In this version, two benches are attached to the table. When all the parts are cut, they need to be sanded, paying special attention to the ends. We varnish each board separately.

The optimal solution for a gazebo is a dining table with benches attached to it.

To connect the parts of the structure, we will prepare studs (length 160 mm), nuts and washers - 24 pcs. For the rest of the connections, we use self-tapping screws or nails of a suitable length. With the help of a drill, it is necessary to prepare all the holes for the fasteners.

According to the drawing, we assemble the tabletop and the upper parts of the benches. We cut the crossbars along the edges, the angle should be 45. It is convenient to do this using a rotary miter box.

We make and attach all the legs to self-tapping screws. We fasten the parts cut at an angle.

We varnish each board separately.

We tighten the product with studs and bolts. The holes for the studs must be pre-drilled with a drill. When installing the stud, you need to put on washers on both sides and tighten the nuts using a wrench.

We tighten the product with studs and bolts.

We fasten the seat boards with gaps of 5 mm or more. When the seats are connected to the sawn-off supports, we attach them to the assembled base with 160 cm boards: you need 4 boards.

Install the remaining studs and enjoy the result.

With the help of a drill, it is necessary to prepare all the holes for the fasteners.

VIDEO: Do-it-yourself wooden table in the gazebo

50 photo ideas: how to make this table with your own hands

Making a dining table with your own hands will take a little skill and a lot of time and patience. If the carpentry skills are well developed, and at home there is a full set of tools (from a circular saw to a milling machine), then such work will be completely simple. In this case, you can choose the option of making a table that matches not only skills, but also financial capabilities.

The choice of materials and the size of the future table

The dining table is the center of the kitchen or dining room, even if it sits under a wall. Its size should be selected depending on the size of the room and the number of people who often dine together. A comfortable area for one person at the table is 60 cm.Total, for a family of 4 people, there will be enough tabletops with dimensions of 80x60 cm.But sometimes you have to receive guests, so it is better to increase the size of the table to the most suitable for the dimensions of the room.

So it will take up a minimum of space, but if necessary, the useful area is doubled. In this case, it is better not to make the table attached to one wall, because sometimes you may need to move it to another room.

What is the best way to make a dining table?

Solid oak is an ideal material for a kitchen table. Strong, durable and wear-resistant material will last more than one generation with proper care. Pine, on the other hand, is much softer and easier to process, so it is better suited for novice builders. If you take a ready-made furniture board, you do not have to adjust and fasten the boards yourself, but such a tabletop will cost more.

It is advisable to choose sturdy wood for the legs - they must support the weight of the countertop with numerous dishes and plates. In addition, a table is often used instead of a stepladder - this must also be taken into account when choosing wood. Natural wood can be stained, varnished or painted in any color. Or experiment with combining different types of finishes and even change the style every year.

If you need maximum savings, you can buy a laminated chipboard board, since the choice of decorative coatings is extremely wide - like natural wood, plastic, monochromatic and colored. If you order a sheet of the required size, assembly will take a minimum of time. But you need to choose only products with a durable top coating and insulate the edge of the countertop well, otherwise, if moisture gets in, the surface will begin to "swell".

How to make a simple dining table

For those who decide to start making furniture with their own hands for the first time, a simple rectangular table with a chipboard top is best suited. It will require:

- Purchase a sheet of chipboard of the required size.

- Buy 4 legs - these can be ready-made balusters or bars with a square section of at least 5x5 cm, which will have to be adjusted in height and sanded with sandpaper. In addition, metal chrome legs can be found which will give the table a modern and stylish look. The included mounts make it as easy as possible to assemble the table.

- If the legs are wooden, the frame is assembled from the facing boards - for a stronger fixation. The crossbars are attached to the legs on the sides - with self-tapping screws on metal corners from the inside.

- Legs are attached to the table top 10 cm from the edge. Wooden - on corners, metal - using ready-made fasteners. The frame to the table top is also fixed from the inside with corners - one on each side.

- The wood is treated with wood stain or painted with a preliminary primer - depending on the chosen style.

- A cut of a chipboard sheet is closed with a furniture edge. It is very convenient to use a rigid U-shaped PVC edging. Silicone sealant is generously applied to its inner side (to prevent moisture ingress) and simply snaps onto the edge. The ends are closed with plugs, and the excess sealant is removed.

- If the table top is round or curved, you can take a flexible profile - it is attached to the sealant, the edges are cut off after the glue has set. The flexible piping allows you to create an edge with only one seam, which significantly improves the appearance.

- For greater reliability, you can use a T-shaped profile, but for it you will have to mill the groove clearly in the center of the entire edge - and not everyone has a manual router. But such an edging with wide antennae perfectly hides the uneven cut edges, if they are replete with chips and cracks. Such defects cannot be hidden with a regular edge.

The advantage of a chipboard table is its maximum simplicity and cost-effectiveness. To assemble it, you need a minimum of tools:

- screwdriver or screwdriver;

- sharp knife for edge cutting;

- sandpaper for grinding wooden legs;

- brush for coating wooden parts.

Folding table-book - for all occasions

In order not to think about placing guests on the floor in the best Japanese traditions, a folding dining table is ideal for a small apartment. How to make a folding table with a swivel mechanism?

No more complicated than a regular rectangular table, just a little more expensive:

In addition, you can make a sliding table. In this case, the frame is made "half". One part is screwed to the lower tabletop in the usual way, and the second is made wider so that it can go onto the first. Full extension telescopic guides are fixed on the outside of the narrow part of the frame and the inside of the wide part. But this design is still less reliable than a rigidly fixed frame.

How to add originality to the table?

If you want to make the table special and have the opportunity to realize your idea, why not give it a try? For example, make it glow or decorate with tiles.

Glowing table - how to impress guests

For such a table, a tree with defects is specially selected - chips, cracks and holes from knots. First, the boards are sized and glued together. For better fixation, they can be attached to wooden chopiks - dowels:

If you need to fill through holes, boards covered with waxed paper are placed under them. You can take ordinary parchment for baking. To prevent the resin from spilling over the edge of the edge, you can stick an adhesive tape on it so that it rises a centimeter above the surface. To make even edges at the chipped board, formwork is made, which is also covered with paper and filled with epoxy.

After the first layer has dried, the table top is sprayed and sanded "wet" with fine sandpaper, dried and a second layer of paint is applied. This continues until a perfect shine is obtained. In addition, the wood will be protected from moisture, which is very important for the kitchen table.

Ceramic table - practical and durable

The basis for ceramic tiles can be any - an old tabletop, a sheet of metal or an OSB plate. The choice of decor is also unlimited, although the mosaic looks better. To simplify the work, you can buy a ready-made mosaic on a grid - you don't have to assemble it yourself, and the thickness is minimal, which is quite important for table decor.

Tile adhesive is applied to the countertop with a notched trowel. The pattern is laid from the corners along the outer perimeter of the countertop, gradually filling the entire surface.

After the glue has completely dried, grout is applied and as soon as it dries, the excess is wiped off with a damp sponge. If you add sunflower oil to the water, the grout evens out in the joints and does not cling to the sponge.

To protect the edge of the countertop, it is sealed with masking tape, which is removed after the grout has dried. If the edge needs processing, it can be painted in a contrasting color, which will give the table even more originality, or completely covered with the same tiles.

The mosaic laid out only in the center of the table looks original. In this case, a tree is selected to the height of the tiles with a jigsaw and a mosaic is laid out in the resulting depression.

Even if it was not possible to maintain the same depth, the height of the tiles can be adjusted by increasing and decreasing the adhesive layer. The main thing is that the table top is flat, so each row of tiles is checked with a level.

You don't have to buy expensive materials if you can use something that no one else needs. How to make an original and beautiful dining table for a summer residence from old pallets can be seen in the video:

This piece of furniture is one of the most versatile in use. The table can be a dining room, utility table, installed in a living room, on a veranda, on the territory, in a workshop, and so on. In a word, it is impossible to do without it. But many people do not like purchased products for a number of parameters - size, design features, shape, or for another reason.

Considering that the tree is relatively easy to cut, polish, make a table out of it according to your own drawing, it is not a problem for a good owner with your own hands. And it will come out much cheaper. Plus - the satisfaction of such work.

Premises

Ideally, this is an extension, a shed, an empty garage, although a small covered area will do. Working with wood in the open air means completely dependent on the vagaries of the weather. If there are "square meters" suitable for the manufacture of furniture, then you should worry about high-quality ventilation in advance. Natural is sometimes not enough (besides, it depends on the change in wind direction and pressure), and an exhaust hood is installed.

Arguments that if you use protective equipment, you can work in an enclosed space, do not stand up to scrutiny. Wood dust will immediately settle on everything, including on the sample with which some action is performed. Neither an accurate cut along the line, nor a high-quality surface treatment of wood (not to mention impregnation and finishing with a paint and varnish composition) can be obtained.

One cannot but take into account the fact that many preparations used for processing wood contain toxic components. For example, varnishes, paints, impregnations, if they are not natural, then harmful fumes are guaranteed.

Instruments

Their set depends on the extent to which it is planned to "refine" a simple structure of wood, what shape it should be given, and a number of other nuances. If the master does not claim the grace of a wooden table, does not aim to achieve its originality, then the usual carpentry set will be enough.

For more "delicate" work in the process of making a table of unusual shapes, external design, you will need special devices.

El / jigsaw. It will not be possible to make an inclined vertical cut with an ordinary saw, keeping the angle exactly. The canvas will "play", and therefore the quality of work will be extremely low. The electric jigsaw is versatile in use, moreover, it gives a high accuracy of cutting a tree or cutouts in it.

Many of the listed fixtures can be rented if making furniture is not a hobby, but a necessity.

Impregnating and other compositions

Rotting protection:

- Dealing with engine oil is an effective and free tool. But not for dining tables.

- Linseed oil. A natural and effective product that penetrates deeply into the structure of the tree and protects it from mold and mildew. The downside is the high cost. But if the table is intended for eating - a great option. The drug has no color, therefore, after processing lumber, it does not leave any traces in the form of darkening, stains, streaks, in contrast to working off.

- Water-polymer emulsion. It is characterized by long-term action and health safety.

- Acrylic varnishes. They have practically supplanted their predecessors of the "NC" category, since they are harmless and in many respects better than the compositions that are diluted with solvents.

- PVA, bone glue and a number of others. More information on joinery -.

For decorating a tree:

- Colorless varnishes are used not only to protect materials from moisture. With their help, you can save the texture of the wood, shade it.

- Stains.

- Varnishes with a coloring effect (tinting).

- Paints (but only for wood!).

- Putties.

Using colorless varnish and pigments, you can make a coloring composition, and of any shade. It is enough only to correctly determine the proportion of the components. This is easy to do by experimenting with mixing and applying a sample to the rejected board. This will help you find an acceptable tone. It is more than advisable, since it is not always possible to buy exactly what you need on the market.

Fasteners

All advice on assembling a wooden table with nails (argumentation - simple, fast and cheap) is better to ignore. The reasons are as follows:

- A nail easily pricks dry wood (and this is what is taken; more on that below).

- It is rather difficult to correctly direct its leg (strictly vertically). In some cases, it is even more difficult to redo your mistake.

- The tree, even the most protected from rot, succumbs to it over time. The maintainability of a table knocked down by nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2 - 3 will have to be changed.

- When assembling a wooden table, if glue alone is not enough, only self-tapping screws should be used.

- Sometimes its individual parts (at the joints) require reinforcement. Strengthening the strength with a hardware with a thicker and longer leg is impractical. The reason is the same - the likelihood of splitting the tree. For these purposes, metal strips, staples, corners are used.

Features of the choice of wood

Someone is guided by the cost of lumber, another is important the resistance of the tree to decay, for the third - its texture. What can you recommend for a novice furniture maker? Do not use for a table, unless it is intended to be installed somewhere in a utility room or garage, the same type of wood. This is exactly what many novice "craftsmen" do, picking up the same type of boards and bars from what is left of construction or repairs and gathering dust in the barn.

When making a wooden table for living quarters, verandas, and so on, you need to take into account the properties of individual species. Naturally, if you don't have enough experience in assembling furniture, you should pay attention to cheaper wood. The first table in life (chair, stool) is just a kind of training in making, gaining experience.

Table top. Here, strength and minimum moisture absorption are in the first place. It is on this part of the table that something is constantly spilled. The optimal choice is pine, larch, oak (although the latter is more expensive). Thickness - at least 3 cm.If the dimensions of the countertops are small, then wood-based panel products (, OSV and the like) can be used. But only with lamination to prevent swelling of the material when liquid hits the table surface. For example, laminated chipboard.

Low-grade sawn timber is not used in the furniture industry. This is not economically feasible, as pre-treatment of the wood increases the production cycle. But in the manufacture of something, wood of lower grades, substandard - just right. The same pallets left over after using stacks of foam blocks or bricks.

And not only because it's free or relatively cheap. With a competent approach, many disadvantages of such wood can be turned into advantages. For example, after coating with a colorless varnish, the tabletop takes on a unique original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, knots falling out and wormholes.

If pine is chosen for the countertop (this also applies to many other conifers), then you need to pay attention to the location of the annual rings. These arcs are called humps. The cuts of the boards show how they are oriented, and this is taken into account in the process of laying them in a row. Samples obtained by the tangential sawing method are arranged alternately (the top is down, the next one is up); radial cutting - the same (arcs in one direction). The nuance is insignificant, but it is precisely the observance of this recommendation that eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. During wood shrinkage, it will deform; this is a natural process, and its consequences in the form of twisting, warping, bending are inevitable. Such a table will quickly become warped, and you will have to repair it. And here you need to decide - to purchase high drying wood or to rid it of moisture on your own. The first option is simpler, but such a tree is more expensive. The second is cheaper, but there are a number of purely technical difficulties.

- Firstly, it is necessary to ensure a stable temperature regime at the place of storage of blanks. Changes in its value will lead to uneven moisture evaporation, which will negatively affect the strength of the tree.

- Secondly, there must be good ventilation.

- Thirdly, and, perhaps, this is the most unpleasant moment - you will have to wait, up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be expected; even in this case it takes practice.

This once again confirms the idea that when starting to make furniture out of wood for the first time, one should focus on the simplest table for household needs made of cheap lumber, without claims to its sophistication and originality of the design. For example, for a barn, garage and the like.

Variants and schemes of wooden tables

It should be noted right away that any work related to design and self-assembly is a creative process. In this case, stereotypes do not exist, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wood tables can be. For example, for summer cottages, small utility rooms, it is worth choosing structures whose geometry can be easily changed - folding, camping, suspended, garden, level, and so on.

Tables that are supposed to be used for eating, playing, as magazine tables for installation in living rooms for their intended purpose, are made stationary, that is, unchanged in size. These assemblies are more "solid", since all mating parts are rigidly fixed; no swivel joints.

Features of the assembly of wooden tables

If a person undertakes to make something, it means that he knows how to use the tool, read the drawings and work with lumber. It is not necessary to teach such a home craftsman the basics of carpentry. But a number of nuances in the manufacture of a wooden table will be worth noting. These notes will only help in the process.

Let's start with the types of connections. There are quite a few of them, but for a table that is assembled with your own hands, the following are quite enough.

On dowels

In this case, the fastening of the parts is done by landing on the adhesive (Fig. 1 - 3).

The nuance is that for the manufacture of "cylinders", which are inserted into pre-drilled "channels", a tree of a denser structure is taken than the elements of the table. This is what ensures the strength of the joints. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are commercially available in any furniture showroom in several standard sizes. Grinding them, even having a carpentry machine, is a waste of time. It is not recommended to purchase plastic dowels for the table; they are used for dismountable connections. For example, frame furniture (walls, multi-level shelving, etc.).

It is not worth using nails to fix the table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - the "shuttle" will begin, especially if the table is intended for installation on the territory or in an unheated room.

On kings

It is advisable to make such connections if the table has to be disassembled either periodically, or without this it cannot be transferred through the doorway. Although not all drawers involve dismantling the structure. The most commonly used options are shown in the figures.

Bolted

Such connections are mainly used for garden furniture or furniture installed in outbuildings; for household tables. An example is shown in the figure.

The nuance of working with fasteners

To make the self-tapping screw easy to screw in and "go" in the desired direction, a hole is made at the point of its installation with a drill slightly smaller in diameter than the fastener leg. The main thing is to maintain the coincidence of the center lines, that is, to avoid skewing. In this case, you can do without a screwdriver to "land" the self-tapping screw.

Features of wood processing

Everyone knows that a plane is used first, an abrasive with a coarse grain, and then a fine one. But sometimes it turns out that the last stage, grinding, has to be done many times. Much depends on the type of wood and the degree of its drying. After applying the first layer of varnish, the villi can "stand up". Nothing wrong with that. Wait until the workpiece dries and repeat abrading it. The work is painstaking and takes time. But it is precisely by this technique that you can bring the "problem" wood to the ideal "smoothness".

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of exterior decoration

- Small defects in the form of cracks, chips are eliminated with a putty compound.

- After sanding is complete, remove all wood dust. In this case, an ordinary household vacuum cleaner with an appropriate attachment will help out. After such cleaning, it is recommended to wipe the entire table with a slightly damp cloth, let it dry and repeat the cleaning of the remaining dust. After that, you can safely start applying stain or varnish - there will be no "pellets" on the wood.

- You can add originality to the table not only with the help of curly cutouts, the unusual shape of the table top or legs, the combination of the texture of different breeds, and so on. One of the good options is art painting.

And finally. The work on self-production of something from wood (the same table) is just the initial stage of mastering the skill of a "constructor-assembler". Having worked out technologies, methods on wood, having acquired the necessary skills, it is enough just to switch to other materials - metal, plastic, glass. So the benefits of a wooden table made from even the simplest drawing (besides the pleasure of work and the saved money) are obvious - not wasted time.

One of the essential attributes of human habitation is a table. It should be in the apartment, in the cottage, and in the summer house in the country.

Making a wooden table with your own hands is not such a difficult task as it seems at first glance. A simple structure that is suitable for a summer residence can be assembled by absolutely anyone, even if he first picked up a carpentry tool.

More complex models that will decorate the kitchen or living room will require creativity and certain skills, but this work is doable if you follow certain rules.

Possible options

Despite its simplicity, the table is considered a variable product and, with the right approach, will organically fit into any room. Manufacturers of wooden furniture usually offer the consumer the following types of models:

- with the correct geometry - rectangular, round, oval;

- corner - help to save internal space;

- transformers - multifunctional structures;

- folding and sliding - allow you to accommodate a large number of guests;

- "Books" are a common modification of a folding table.

It is noteworthy, but all of the listed table options can be made in artisanal conditions, literally from scrap materials.

Regardless of design and shape, a homemade wooden table must meet two requirements. Firstly, it must match the interior of the room, if you do not follow this rule, even a beautifully decorated carved tabletop will look unpresentable. Secondly, the width of one seat must be at least 70 cm, otherwise people will experience discomfort.

Otherwise, the width and height are selected individually, depending on personal preferences and the intended use of the table.

Preparatory stage

Even a simple rectangular table with four legs cannot be made without some preparation. Let's figure out what a home craftsman needs in the production process.

Blueprints

This is a prerequisite that will allow you to visually represent the future table, to determine the size and amount of material. You can search for ready-made drawings on the Internet: many craftsmen willingly share the results of their work with Internet users, detailing each stage of production.

If we are talking about a unique table design, which is planned to be created according to your own project, you cannot do without a drawing. You can draw a future model with a simple pencil on a regular notebook sheet. It is recommended to pay special attention to the following points:

- external dimensions (length, width, height);

- fastening the legs to the table top. Round models usually have one support leg located in the center, rectangular structures require 1 support for each corner;

- mechanisms (relevant for folding options and transforming tables).

It is necessary to carefully consider how all the details of the table will be assembled together, what additional processing of the wood will be required before or after assembly.

Material

It is no secret that wood of different species has different properties and not the whole array is suitable for handicraft processing. Depending on the species, all wood can be conditionally divided into 3 groups.

Soft. This includes almost all conifers (spruce, pine, fir, cedar) and many deciduous (linden, aspen, poplar, alder). Such material is easy to process, but the manufactured table will require additional protective coating, especially if it is supposed to be used outdoors. Coniferous wood is dependent on external factors, prone to deformation and cracking. The exception, perhaps, is larch, which is used in construction wherever possible, including for the manufacture of tables.

Solid. This group includes birch, oak, walnut and fruit trees: plum, pear, apple, apricot. Such a bar, even without impregnation, is resistant to a humid environment and exposure to direct sunlight, but in the process of processing one cannot do without a power tool.

Extra strong. This category includes boxwood, acacia, hornbeam and yew. The material has high consumer properties, but requires professional processing, which is possible only in the shops of industrial enterprises.

Tool

The simplest rough table made of boards can be assembled with your own hands with just a hammer, nails and a hacksaw. But for a more accurate execution, additional tools are required:

- electric jigsaw;

- grinder;

- screwdriwer set;

- drill with a set of drills of various diameters;

- roulette;

- simple pencil;

- square.

In addition, it is recommended to pre-treat the wood with special antiseptics, which will make the finished product more durable and resistant to moisture. If you plan to cut a pattern on the legs or sides, then you will need special cutters. A lathe or milling machine for wood will be of great help to the master, but not everyone has such tools.

Homemade tables for a summer residence

The simplest and most practical option for arranging a summer cottage is a table made of wooden pallets. At first glance, unnecessary pallets are a ready-made raw material that practically does not require additional processing, but offers several options for use. For example, from 2 pallets you can make a small hanging table with a wall mount, which can be used as a shelf or for small friendly gatherings.

Such a structure is made elementary. One pallet is fixed to the wall with nails or self-tapping screws. The installation height is selected individually. The working part is attached to the fixed base - the table top. The elements are articulated with two chains, which will perform a supporting and supporting function. For ease of use, 2 hinges are placed at the junction of the pallets; in addition, you can install a locking mechanism, for example, a hook, which will hold such a table in a closed position.

A more complex option is a pallet coffee table that will look organic on a veranda or terrace. In this case, the pallets are carefully disassembled into their component parts, polished, and painted. After that, the boards are hammered into a rectangular tabletop, fixed along the perimeter with vertically arranged elements. The function of the legs is performed by 4 square bars. Such a structure is made in 3-4 hours and is quite suitable for evening teas and family vacations.

We use the remnants of building materials

Practically on any personal plot there are boards left after the construction of a house or outbuildings. This material is quite suitable for creating a simple rectangular table that can be placed on the veranda or in the garage, used as a dining or utility table.

Here you need to be guided by the following instruction:

- assembling the frame. To do this, you need 4 boards: 2 long and 2 short. The sides are fastened together with self-tapping screws, forming a regular rectangle. To preserve the geometry, we use a square. At the joints, you can put iron corners, which will give the structure rigidity and reliability;

- fasten the legs... For these purposes, 4 boards or bars are suitable. The length can be chosen arbitrarily: 80-100 cm. Support stands are installed on the inside of the frame, fastened with nails or self-tapping screws;

- stiffening rib . An additional wooden crossbar is nailed approximately in the middle of the legs. A cross member is installed on both sides, making the structure more robust and stable. In addition, these crossbars can subsequently be used to install a shelf where you can place dishes or other small items necessary for the household;

- table top. This is where the remaining boards go, which are best placed across the frame. The material is sawn with a hacksaw along the width of the table, and is attached to the frame with finishing nails.

At the final stage, all surfaces are sanded, primed and varnished. You can paint the table, in which case the tree will last much longer. And if you walk on the boards with a brush for brushing and apply stain on top, you get an antique table.

Table with benches

This option is great for a garden, a structure made of wood is installed permanently, depending on the size chosen, it can comfortably accommodate 8-10 people. A garden table and benches are made from boards separately, then the elements are fastened together with a threaded connection: steel pins.

The manufacturing process begins with the shops. For this, the boards are sawn to size, according to the drawn up drawings. To assemble a bench, you will need:

- 3 long boards that will fit on the seat;

- 4 short pieces, cut at the edges at an angle of 45 ° - the length of these elements should not exceed the width of the seat;

- 4 boards 40-50 cm high - these will be the legs;

- 1 board is 25-30 cm shorter than the length of the seat - stiffening rib.

note that all the listed elements are duplicated, since there are supposed to be 2 benches for such a table.

The shops are assembled according to the following scheme. A longitudinal stiffener is attached to two short cross members. Legs are installed, which are clamped by the remaining segments. For reliability, short parts are drilled through and, together with the legs, are pulled together with pins.

Seat boards are nailed on top of the frame. It is not necessary to put them close to each other, it is better to leave small gaps.

The finished seats are interconnected by four boards 160-180 cm long. Fastening is carried out at the bottom of the legs in such a way that the support posts are clamped by boards on both sides.

After preparing the base, the table is assembled. The table top and areas for the installation of support posts are made according to the principle similar to the benches. The legs themselves are made cruciform, fixed to the longitudinal supports that connect the benches to each other. The result is a comfortable DIY kitchen table that can be used for family gatherings.

Round tables

Despite the specific geometric shape, making a round table with your own hands from wood is not as difficult as it might seem at first glance. In particular, if there is a felling of old trees in the courtyard of a multi-storey building or next to a personal plot, you can get an original round tabletop without any extra effort. For this, a cut from a tree made in the thickest part of the trunk is quite suitable. Such a round, 5-7 centimeters thick, is varnished and can become a key table installed in the hallway.

If you are not lucky with the fallen trees, you can create a round tabletop on your own. This will require 4 boards of the following sizes:

- length - 2000 mm;

- width - 250 mm;

- thickness - 40 mm.

The boards are tightly connected to each other (without fastening), a circle of the required diameter is drawn on the surface. After that, the boards are cut with a jigsaw exactly along the marked line. A rectangular or triangular frame is assembled under the legs from bars. The shape is chosen depending on the number of legs. If 3 support posts are supposed, the frame is made in the shape of a triangle. The elements are fastened together with self-tapping screws, the legs are fixed in a similar way. The tabletop is installed using corners; after assembly, the entire structure is varnished. If you make such a table carefully, then it can be installed in an apartment in the kitchen or in the living room.

An oval table is assembled by a similar principle. The only difference is that on the boards connected to each other, not a circle is drawn, but 2 semi-oval at the ends. The boards are trimmed along the line with a jigsaw. The frame is also made of bars, but has a strictly rectangular shape. Ideally, the frame should be 10-20 cm from the edge of the countertop. Small tables are often used as coffee tables and look especially interesting on curly legs. However, for the manufacture of carved supports, certain knowledge is required, so it is better to order such elements from the furniture industry.

Transforming tables

A folding table made of wood, made by hand and capable of changing its original shape, is a real masterpiece. Folding structures look equally advantageous in the country and fit into the interior of a city apartment. The simplest option is to make a transformer for a personal plot, and you can easily cope with this task on your own.

To surprise guests and get a comfortable picnic table made of wood, you need to assemble 2 benches with high backs. The seat is made of 3 planks connected by crossbars. There is one nuance here: the edge of the cross member, which is located on the side of the backrest, should protrude 10-15 cm beyond the edges of the seat.

Table legs are made in different lengths. A short support leg is placed on the side of the seat, the long one will serve as the basis for the back. Note that the recommended height of the backrest should vary between 60-90 cm. The design feature of the backrest is that it is mounted on a single bolt, which is located in the upper part, and acts as a swivel mechanism. Closer to the seat, a hole is drilled in the rack where the backrest retainer will be inserted.

After completing all the operations, they get 2 benches, on which you can sit quite comfortably, discussing the latest news or watching the sunset. If you raise the backs of these benches and move them closer to each other, you get a table with two rows of seats. Taking into account the width of each backrest, the result is a table top measuring 120-180 cm.

Computer desk

If we are talking about a factory product, a computer desk seems to be a rather complex structure. It has a pull-out keyboard shelf, drawers for storing discs and other items that require experience to make. However, the model of a table made of wood can be significantly simplified, leaving a minimum of parts necessary for working at a computer.

Here you can try to implement this option:

- steel frame in the form of a welded rectangle made of a professional pipe with 4 support legs. On the one hand, a frame is immediately made for the shelf where the system unit will stand, and two similar elements from the other end;

- the table top is made of cut-to-size boards or a sheet of fiberboard;

- the shelves are made of a material similar to the countertop.

All elements are connected to each other by a threaded connection or a corner. Of course, such a design is inferior to factory counterparts in external design, but it costs several times cheaper and does its job quite well.

Processing and exterior finishing

In order for a homemade wooden table to have a presentable appearance and retain its properties as long as possible, all parts are impregnated with a water-polymer emulsion before assembling. It is better to repeat the treatment 2-3 times with an interval of 5 days. After the installation is completed, the surfaces are carefully sanded, minor imperfections are masked with a putty. Then varnish is applied: it is better to choose acrylic-based compositions that are safe to work with.

To extend the service life, it is recommended to protect wooden tables from strong moisture and direct sunlight. In the garden at the dacha, it is better to install them in a shaded place, and cover them with foil in the rain.

Dinner table - an essential attribute of any dining room or kitchens, center of gravity for the whole families and on weekdays, and especially on holidays, when behind him are going relatives and friends. Therefore, the table must be comfortable, of high quality and beautiful.

The stores are big today choice, but it is much more pleasant to make a dining table with your own hands. In addition, it is significant saving for the family budget.

Dining table options

- Extendable dining table. The most popular option. Small for everyday use, with the arrival of guests, this table is significantly increased due to additional countertops.

- Folding table - a great solution for a small kitchen. The easiest option is to the wall table top and support leg.

- Folding table. The classic representative of this type of furniture - When assembled, it resembles a curbstone. It has one narrow frame tabletop and two wide large ones that are located on the sides and unfold.

- A very handy thing that is suitable for both the kitchen and the living room. When folded it can even be unfolded - a full dining table.

What can be made of?

Materials that are used for the manufacture of dining tables, enough:

Materials that are used for the manufacture of dining tables, enough:

- wood;

- Chipboard, chipboard, MDF;

- plastic;

- natural or fake diamond;

- metal;

- glass other.

Each of them has as their own pros, and cons.

- Wood

The solid wood table is a classic. Wood attracts people not only for its beauty, but also because it is easily processed. In addition, the tree is ecological material that has a beneficial effect on human health. Unfortunately, it has its drawbacks. At the table you need to carefully look after. Wood is sensitive to climate change conditions in room. For example, if the room has enough wet or hot, it doesn't do very well on the material. - Glass

whether it be a magazine, lunch or some other, it looks very stylish. But this stuff is tough processed. In addition, not every glass is suitable for a dining table. Need to pick up lasting material. Best for countertops armored glass, the cost of which is very different from the usual one, and processing is carried out only at the factory where it is used special equipment.

Dining table made of wood

So you have decided do dining table on kitchen do it yourself. First of all, you need to decide on dimensions future product, so that it blends harmoniously with the interior.

So you have decided do dining table on kitchen do it yourself. First of all, you need to decide on dimensions future product, so that it blends harmoniously with the interior.

You can take ready-made drawing dining table, if specified in it dimensions meet your requirements.

For example, consider making dining table made of wood.

This simple rectangular a table on four legs will be Great look both in a classic interior and in choosing the appropriate way finishes, you can make a dining table in or in

Materials and tools

Before assembling the table, prepare materials:

Before assembling the table, prepare materials:

- balusters(legs) - 4 pcs. Height - 73 cm. They should not be thin;

- edged boards:

5 x 15 x 100 cm (for table top) - 4 pcs.,

80 cm (long crossbars) - 2 pcs.,

40 cm (short slats) - 2 pcs.; - sandpaper;

- glue carpentry;

- dowels.

Note: countertop boards need polishing.

necessary for making a dining table:

necessary for making a dining table: - pencil, roulette, meter;

- hacksaw, a circular saw or grinder;

- plane;

- drill(drill 8 mm.);

- screwdriver or screwdriver;

- self-tapping screws(30 mm);

- brushes.

Manufacturing steps

Step 1. We make a table top. Planks trim first in width and then in length. Process surface plane. Sand the wood thoroughly so that the worktop becomes smooth. The edges must be well finished. If you do, the boards will tightly adjoin each other.

Make the same marks on the edges of the boards, step back 10-15 cm. Then drill out holes and apply in them joinery glue. Plaster the edges. Then the chopiki must be driven into the holes. Connect boards.

Remove excess glue emery paper. Level the joints between the boards with a plane, grind countertop surface and edges.

Note: if you walk on the countertop with a metal sponge, the wood will become more textured.

Step 2. We fasten the legs and do base for countertops. Balusters must be connected with short crossbars thus:

Step 3. Pairs of legs, connected by short crossbars, are fastened together long crossbars.

Step 4. Drill in long crossbars holes. When the glue is dry, install countertop.

For more strength you can strengthen the structure with additional transverse bars or boards.

How to make a table from a metal profile correctly:

Table finishing

Necessarily more before assembly necessary antiseptic impregnation.

Necessarily more before assembly necessary antiseptic impregnation.

When the work is done and the table is ready, you need to tackle it finishing. First of all - choose Colour your product. It can be absolutely anyone. Best fit oak or walnut, these colors are considered classics.

Give the wood the right shade and even imitate valuable wood species can be used with decorative stains.

For protection from moisture and imparting presentable appearance need to cover the table several layers varnish. Each layer must be thoroughly dried.

If desired, the tabletop can be decorate. For example, interesting and uncomplicated even for a beginner is applicable both for decorating a new product and for restoration dining table do it yourself.

How dining tables are made of wood, see video: